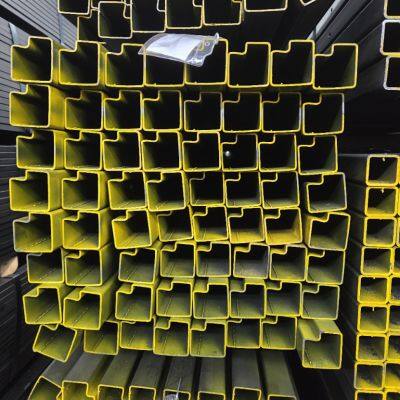

Durable Welded Special Shaped Steel Pipe for Oil and Gas Sector Applications

Engineered for extreme reliability in critical oil and gas operations, our welded special shaped steel pipes deliver unmatched durability in high-pressure and corrosive environments. Manufactured by Hunan Yige Special Steel Science Technology Co., Ltd since 2015, these pipes combine advanced welding techniques with rigorous ISO9004 and ISO14000 certified quality control. With customizable profiles tailored to specific project needs, they ensure seamless integration into pipeline networks while reducing maintenance downtime and lifecycle costs across drilling, transmission, and refining applications.

Key performance advantages include:

- Superior resistance to sulfide stress cracking and hydrogen-induced corrosion

- Precision-formed joints eliminating weak points through continuous weld integrity

- Optimized flow dynamics via custom cross-sections reducing turbulence

- Enhanced structural load-bearing capacity for above-ground installations

- Reduced total ownership costs through extended service lifespan

Technical specifications vary based on application requirements with standard configurations shown below:

| Parameter | Range | Notes |

|---|---|---|

| Cross-Section Dimensions | 20x20mm to 500x500mm | Rectangular/Square profiles |

| Oval Major Axis | Up to 600mm | Minor axis ratio customizable |

| Pressure Rating | Class 300 to 2500 | Per ASME B16.34 standards |

| Temperature Tolerance | -46°C to 350°C | Material-dependent |

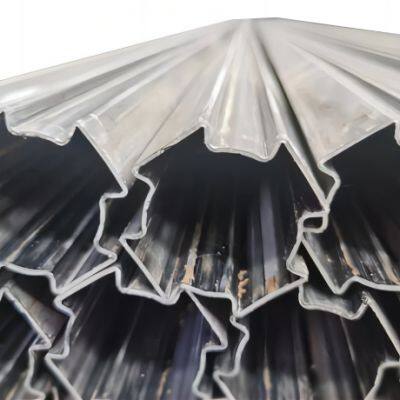

The manufacturing process employs high-frequency induction welding with real-time NDT monitoring, ensuring consistent wall thickness and metallurgical properties. Custom alloy compositions are available for sour service applications requiring HIC resistance. Our 5,000-10,000 sqm facility enables flexible production runs from prototype to bulk quantities with rapid turnaround.

Operational benefits for your projects:

- 15-20% weight reduction versus standard circular pipes in structural applications

- Elimination of field welding through prefabricated connection systems

- Compatibility with common pipeline coatings and cathodic protection

- Third-party mill test reports provided for material traceability

Backed by extensive export experience across 6 continents, we support logistics coordination including bundling and anti-corrosion packaging. With dedicated engineering consultation, we help optimize pipe geometry for your specific flow rates and space constraints.

Frequently Asked Questions:

Q: What certification documentation do you provide?

A: All shipments include material test certificates compliant with ISO9004 and ISO14000, with additional reports available upon request.

Q: Can you produce non-standard shapes like triangular pipes?

A: Yes, our flexible tooling accommodates custom geometries including polygonal and asymmetric profiles for specialized applications.

Q: What is your quality assurance process for welds?

A: We implement automated ultrasonic testing on 100% of welds, supplemented by hydrostatic testing per API 5L standards.

Q: Do you offer surface treatments for offshore applications?

A: Yes, we provide hot-dip galvanizing and specialized epoxy coatings meeting NORSOK M-501 requirements.

Q: What is the typical lead time for custom orders?

A: Standard configurations ship in 3-4 weeks; complex custom projects require 6-8 weeks for tooling and production.

Q: How do you handle international shipping?

A: We arrange containerized shipments with proper cushioning and VCI protection, providing full export documentation.

Leverage our expertise in specialized steel fabrication to enhance your oil and gas infrastructure efficiency. Contact our technical team for project-specific solutions backed by a 15-year design lifespan guarantee. With manufacturing capabilities spanning global markets, we deliver compliant products that meet your most demanding operational challenges.

Send Inquiry to This Supplier

You May Also Like

-

Heat Treatment Shape Steel Pipe Cold Drawn Welded Special Shaped Seamless Steel TubeNegotiableMOQ: 1 Ton

-

S960MC Welded Round Steel Pipe Cold Drawn Welded Special Shaped Steel PipeNegotiableMOQ: 1 Ton

-

Durable Welded Special-shaped Tube Designed for Agricultural Equipment UseNegotiableMOQ: 1 Ton

-

Welded Special-shaped Tube for Automotive Frame Support in Heavy MachineryNegotiableMOQ: 1 Ton

-

High-Strength Welded Special-shaped Tube With Corrosion Resistance for DurabilityNegotiableMOQ: 1 Ton

-

Precision Welded Special-shaped Tube in Alloy Steel for Aerospace EngineeringNegotiableMOQ: 1 Ton

-

Various Dimensions Welded Special-shaped Tube Made From Carbon Steel MaterialNegotiableMOQ: 1 Ton

-

Custom Size Welded Special-shaped Tube in Stainless Steel for Industrial ApplicationsNegotiableMOQ: 1 Ton

-

Welded Special-shaped Tube Used in Construction Industry Structural BeamsNegotiableMOQ: 1 Ton

-

Welded Special-shaped Tube for Marine Industry Shipbuilding ApplicationsNegotiableMOQ: 1 Ton