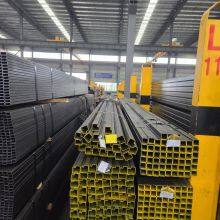

Precision Welded Special Shaped Steel Pipe in Custom Sizes for Engineering Projects

Our Precision Welded Special Shaped Steel Pipe is engineered to meet the rigorous demands of modern engineering projects, offering unparalleled customizability and durability. Designed for seamless integration in construction and infrastructure, it ensures high accuracy in welding and robust performance under stress. With custom sizes tailored to your specifications, this pipe reduces waste and installation time, making it a cost-effective solution for complex applications. Trust in our ISO-certified manufacturing to deliver reliable, long-lasting steel pipes that elevate your project outcomes.

Key features and benefits include:

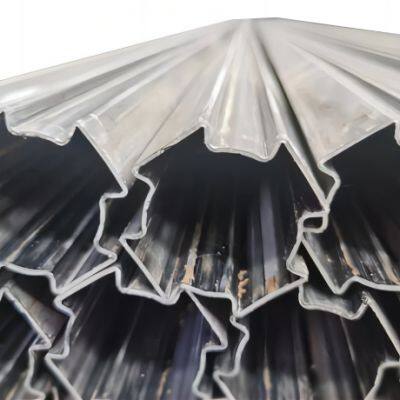

- Superior Welding Precision: Utilizing advanced techniques for consistent, high-quality seams that minimize weak points and enhance structural integrity.

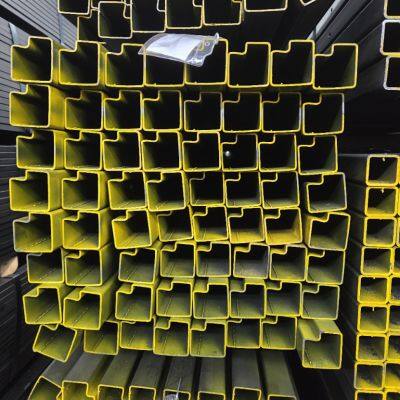

- Versatile Customization: Available in a wide range of sizes and special shapes like rectangular or square, adapting to unique project needs without compromising strength.

- Durable Material Options: Made from carbon steel or alloy steel, providing excellent resistance to corrosion, impact, and environmental stressors for extended service life.

- Cost Efficiency: Reduces material waste and labor costs through precise sizing, while easy installation accelerates project timelines.

Technical specifications and standard options are detailed in the table below, highlighting core parameters for quick reference:

| Parameter | Standard Range | Customizable Options |

|---|---|---|

| Outer Diameter | 10 mm to 500 mm | Available upon request |

| Wall Thickness | 1 mm to 20 mm | Tailored to specifications |

| Length | 6 m standard | Adjustable per project |

| Material Grade | ASTM A53, A106 | Other grades optional |

Applications span various industries, including:

- Construction: Ideal for building frameworks, support columns, and bridges due to high load-bearing capacity.

- Infrastructure Projects: Used in pipelines, drainage systems, and utility installations for reliable fluid transport.

- Industrial Machinery: Fits into equipment manufacturing where custom shapes optimize space and function.

Advantages for clients include reduced downtime through efficient production cycles, backed by ISO9004 and ISO14000 certifications ensuring consistent quality and environmental compliance. For custom orders, our large-scale facility enables flexible manufacturing with minimal lead times. Experience the difference with a product that adapts to your vision while maintaining industry standards.

Ready to enhance your engineering projects? Contact us today for a personalized quote or to discuss specific requirements. Our team at Hunan Yige is committed to delivering solutions that exceed expectations, with global shipping to key markets like North America and Southeast Asia. Invest in precision and reliability—inquire now to start your order.

Frequently Asked Questions (FAQ)

-

What materials are used in your steel pipes?

Our pipes are typically made from carbon steel or alloy steel, offering durability and corrosion resistance. Material selection can be customized based on project needs. -

Can I order non-standard sizes or shapes?

Yes, custom sizes and special shapes are available upon request. We tailor dimensions to fit unique engineering requirements. -

What certifications do you hold for quality assurance?

We are certified to ISO9004 and ISO14000 standards, ensuring consistent quality control and environmental management in production. -

How long does delivery take for custom orders?

Delivery times vary based on order complexity but are optimized for efficiency. Typical lead times range from 2-4 weeks, with expedited options available. -

What surface treatments are offered?

Optional coatings, such as galvanizing or painting, can be applied to enhance corrosion resistance. These are customizable per client specifications. -

Do you provide samples before bulk orders?

Samples are available upon request for evaluation, allowing you to verify quality and fit before committing to larger quantities. -

What industries commonly use your steel pipes?

They are widely used in construction, infrastructure, and industrial applications, including bridges, buildings, and machinery.

Send Inquiry to This Supplier

You May Also Like

-

S960MC Welded Round Steel Pipe Cold Drawn Welded Special Shaped Steel PipeNegotiableMOQ: 1 Ton

-

Durable Welded Special-shaped Tube Designed for Agricultural Equipment UseNegotiableMOQ: 1 Ton

-

Welded Special-shaped Tube for Automotive Frame Support in Heavy MachineryNegotiableMOQ: 1 Ton

-

High-Strength Welded Special-shaped Tube With Corrosion Resistance for DurabilityNegotiableMOQ: 1 Ton

-

Precision Welded Special-shaped Tube in Alloy Steel for Aerospace EngineeringNegotiableMOQ: 1 Ton

-

Various Dimensions Welded Special-shaped Tube Made From Carbon Steel MaterialNegotiableMOQ: 1 Ton

-

Custom Size Welded Special-shaped Tube in Stainless Steel for Industrial ApplicationsNegotiableMOQ: 1 Ton

-

Welded Special-shaped Tube Used in Construction Industry Structural BeamsNegotiableMOQ: 1 Ton

-

Welded Special-shaped Tube for Marine Industry Shipbuilding ApplicationsNegotiableMOQ: 1 Ton

-

Welded Special-shaped Tube in Custom Shapes for Architectural Design ProjectsNegotiableMOQ: 1 Ton