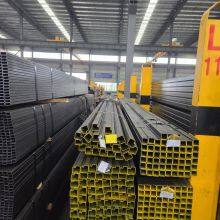

Industrial-Grade Welded Special Shaped Steel Pipe With Enhanced Load-Bearing Capacity

Engineered for demanding industrial applications, our welded special shaped steel pipes deliver unmatched structural integrity and load-bearing performance. Manufactured by Hunan Yige Special Steel with precision welding technology, these pipes provide exceptional strength-to-weight ratios while accommodating complex geometric requirements.

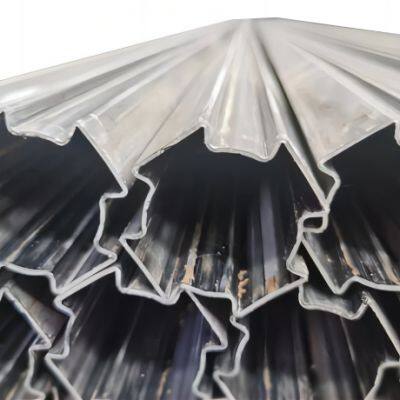

The enhanced load-bearing capacity is achieved through:

- Optimized material selection of high-grade carbon steel

- Advanced high-frequency induction welding techniques

- Precision-formed cross-sections for stress distribution

- Rigorous quality control throughout manufacturing

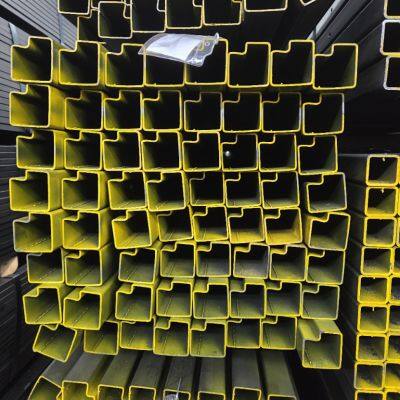

Technical specifications include:

| Parameter | Standard Range | Custom Options |

| Outer Dimensions | 50×50mm to 500×500mm | Customer drawings accepted |

| Tensile Strength | ≥410 MPa | Higher grades available |

| Length | 6m / 12m standard | Cut-to-length service |

Industrial applications span across:

- Structural frameworks for commercial buildings

- Heavy machinery support systems

- Material handling conveyor structures

- Bridge and infrastructure components

Our manufacturing capabilities include pre-production prototyping and third-party inspection coordination to ensure dimensional accuracy and welding integrity meet project specifications.

Frequently Asked Questions:

Q: What tolerance standards do you maintain?

A: We adhere to EN 10219 dimensional tolerances with ±0.5mm accuracy for critical dimensions, verified through laser measurement systems.

Q: Can you accommodate non-standard alloy requirements?

A: Special material compositions can be sourced based on project specifications with advance consultation.

Q: What welding methods are employed?

A: We utilize HFIW (High Frequency Induction Welding) with automated seam tracking for consistent penetration and minimal heat distortion.

Q: How do you ensure corrosion resistance?

A: Multiple surface preparation options include shot blasting to SA 2.5 standard and various coating systems based on environmental exposure.

Q: What documentation accompanies shipments?

A: All shipments include material test certificates, dimensional reports, and compliance documentation matching order specifications.

Backed by ISO-certified manufacturing processes and a decade of metallurgical expertise, our special shaped steel pipes provide reliable structural solutions for global engineering projects. Contact our technical team for project-specific load calculations and manufacturing feasibility assessments.

Send Inquiry to This Supplier

You May Also Like

-

Custom-Sized Welded Special Shaped Steel Pipe Compatible With Industrial Piping SystemsNegotiableMOQ: 1 Ton

-

Welded Special Shaped Steel Pipe for Structural Applications in Construction IndustryNegotiableMOQ: 1 Ton

-

S960MC Welded Round Steel Pipe Cold Drawn Welded Special Shaped Steel PipeNegotiableMOQ: 1 Ton

-

Post Weld Heat Treatment Special Shape Steel Pipe Cold Drawn Welded Seamless TubeNegotiableMOQ: 1 Ton

-

Heat Treatment Shape Steel Pipe Cold Drawn Welded Special Shaped Seamless Steel TubeNegotiableMOQ: 1 Ton

-

S960MC Welded Round Steel Pipe Cold Drawn Welded Special Shaped Steel PipeNegotiableMOQ: 1 Ton

-

Durable Welded Special-shaped Tube Designed for Agricultural Equipment UseNegotiableMOQ: 1 Ton

-

Welded Special-shaped Tube for Automotive Frame Support in Heavy MachineryNegotiableMOQ: 1 Ton

-

High-Strength Welded Special-shaped Tube With Corrosion Resistance for DurabilityNegotiableMOQ: 1 Ton

-

Precision Welded Special-shaped Tube in Alloy Steel for Aerospace EngineeringNegotiableMOQ: 1 Ton