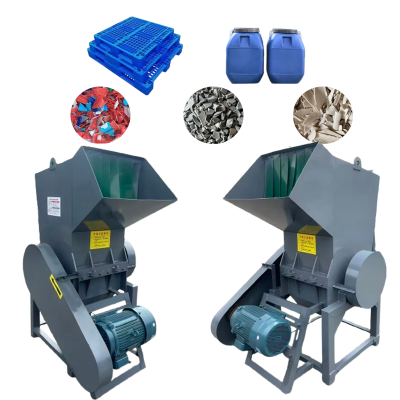

High-Efficiency Plastic Basket Crusher Featuring Low Energy Consumption and Quiet Operation

Transform your plastic recycling operations with the High-Efficiency Plastic Basket Crusher from Panqi Heavy Industry. Engineered for exceptional energy savings and remarkably quiet performance, this industrial-grade crusher delivers unmatched processing efficiency while significantly reducing operational costs. The innovative design ensures rapid size reduction of plastic baskets and crates with minimal power consumption, making it an ideal solution for sustainable waste management systems.

Featuring advanced cutting technology and robust construction, our crusher maintains consistent performance even during continuous operation. Manufacturers will appreciate the significantly reduced noise pollution that creates safer, more comfortable working environments. With flexible capacity options and adaptable configurations, this machine seamlessly integrates into existing production lines while delivering measurable ROI through energy conservation and increased processing throughput.

Core Technical Advantages:

Patented rotor design with reversible cutting blades for extended service life

Intelligent power management system reducing energy consumption by up to 40%

Multi-layer acoustic insulation achieving workplace-friendly noise levels

Quick-release mechanism for blade maintenance without disassembly

Vibration-dampening mounts protecting surrounding equipment

Standard Performance Specifications:

| Model | Power (kW) | Capacity (kg/h) | Weight (kg) |

|---|---|---|---|

| PBC-300 | 7.5 | 100-150 | 850 |

| PBC-600 | 15 | 250-300 | 1250 |

| PBC-900 | 22 | 350-450 | 1850 |

Note: Custom configurations available upon request

Operational Benefits:

Reduced electricity costs through optimized motor efficiency

Minimized maintenance requirements with accessible service points

Enhanced workplace safety with emergency stop systems

Compatibility with various plastic types including PP, HDPE, PET

Compact footprint allowing flexible facility layout options

The cutting chamber incorporates hardened steel blades arranged in staggered configuration, ensuring thorough fragmentation of plastic baskets without jamming. An integrated screening system allows precise control of output particle size ranging from 10-50mm, ideal for subsequent processing stages. Safety features include overload protection and magnetic separation to prevent metal contaminants from damaging the rotor assembly.

Backed by Panqi Heavy Industry's manufacturing expertise since 2019, this crusher represents our commitment to developing environmentally responsible recycling technology. With comprehensive technical support and worldwide distribution capabilities, we ensure prompt delivery and installation guidance regardless of your location.

Ready to enhance your recycling efficiency?

Contact our engineering team today to discuss your specific processing requirements and discover how our low-consumption crusher can optimize your operations while reducing environmental impact.

Frequently Asked Questions

Q: What maintenance does this crusher require?

A: Routine maintenance includes blade inspection every 300 operational hours and lubrication of bearings every 150 hours. The modular design allows quick component replacement without specialized tools.

Q: Can it process plastic baskets with metal components?

A: Yes, the integrated magnetic separator effectively removes ferrous contaminants. For non-ferrous metals, optional detection systems can be incorporated.

Q: What safety features are included?

A> Standard safety systems include emergency stop buttons, electrical overload protection, and interlocked access doors that automatically shut down operation when opened.

Q: How does it achieve such low noise levels?

A: Our proprietary noise reduction technology combines vibration-dampening mounts, acoustic insulation panels, and specially designed cutting geometry that minimizes operational resonance.

Q: What after-sales support is available?

A: We provide comprehensive technical support including remote diagnostics, operator training programs, and worldwide spare parts availability within 48 hours for critical components.

Send Inquiry to This Supplier

You May Also Like

-

Versatile Plastic Shredder Crusher for Recycling HDPE LDPE PP Waste With Easy MaintenanceNegotiableMOQ: 1 Combo

-

Industrial Plastic Crusher Machine for Grinding Pipes Bottles Films With Safety ProtectionNegotiableMOQ: 1 Combo

-

Powerful Plastic Shredder Crusher Machine With High Output for Recycling Plastic MaterialsNegotiableMOQ: 1 Combo

-

Industrial Plastic Granulator Crusher Machine for Plastic Pipes Sheets Bottles Waste RecyclingNegotiableMOQ: 1 Combo

-

Automatic Plastic Crusher Grinder for Recycling HDPE LDPE PP Materials With CE CertificationNegotiableMOQ: 1 Combo

-

High Capacity Plastic Crusher for Recycling Pipes Sheets Bottles With Durable BladesNegotiableMOQ: 1 Combo

-

Robust Plastic Crusher Granulator for Recycling Plastic Materials With High Crushing EfficiencyNegotiableMOQ: 1 Combo

-

Heavy Duty Plastic Crusher for Recycling HDPE LDPE PP Pipes Sheets Bottles With High EfficiencyNegotiableMOQ: 1 Combo

-

PQ Series Plastic Crusher 200-2000kg/h for Recycling PET Bottles & Plastic BarrelsNegotiableMOQ: 1 Combo

-

China High Quality Plastic Crusher EquipmentUS$ 1800MOQ: 1 Set