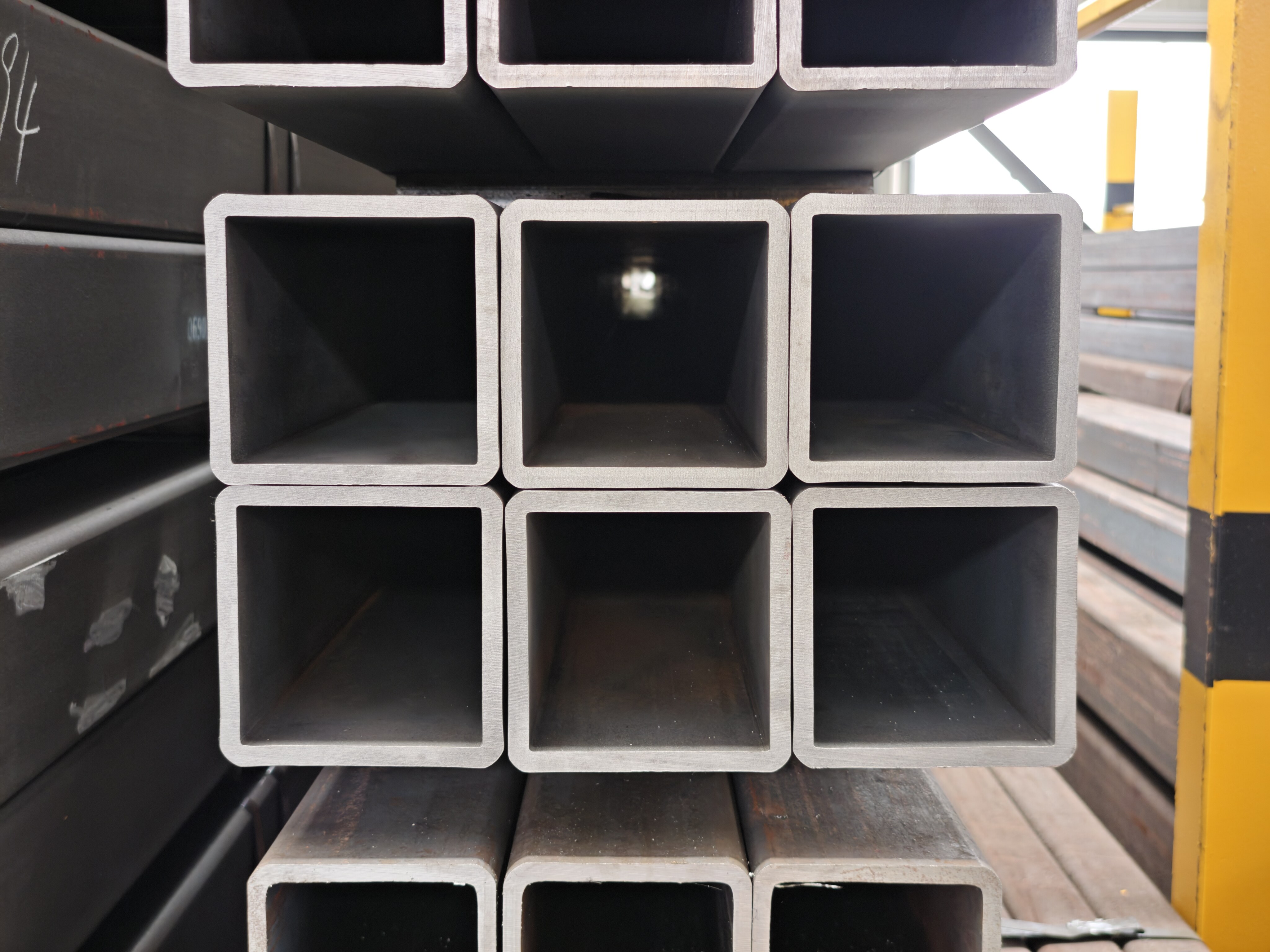

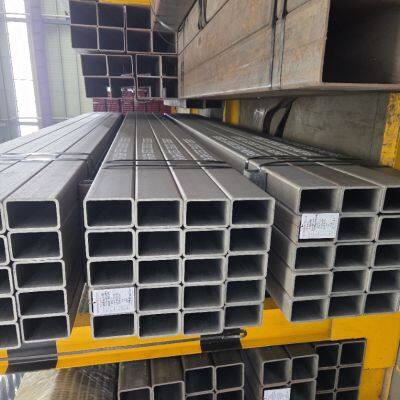

Seamless Rectangular Steel Pipe Used in Automotive and Machinery Industries for Component Fabrication

Premium seamless rectangular steel pipes engineered for precision component fabrication in demanding automotive and machinery applications. Our pipes deliver exceptional dimensional accuracy and structural integrity, enabling manufacturers to create reliable, high-performance parts while reducing production downtime. With ISO-certified quality control processes, we ensure consistent material properties critical for safety-critical components.

Key advantages include:

Enhanced fatigue resistance for dynamic load-bearing applications

Superior surface finish minimizing post-processing requirements

Optimized weight-to-strength ratio improving fuel efficiency in automotive systems

Excellent weldability and machinability for complex fabrication

Technical specifications vary based on custom requirements. Standard parameters include:

| Parameter | Range | Standard |

|---|---|---|

| Tensile Strength | 310-550 MPa | ASTM A500 |

| Corrosion Resistance | Class 2-4 | ISO 9227 |

| Dimensional Tolerance | ±0.5mm | EN 10219 |

Our manufacturing facility features advanced cold-drawing technology that achieves precise wall thickness uniformity, crucial for hydraulic cylinder components and machinery frames. The seamless construction eliminates weak points common in welded alternatives, significantly extending service life in high-vibration environments. Automotive clients benefit from reduced part weight without compromising crash-test performance, while machinery builders gain components with improved torsional rigidity.

Partner with our ISO-certified facility for just-in-time delivery to global markets. Request material test reports and custom samples to verify performance in your specific application. Our engineering team provides technical consultation to optimize pipe specifications for your component design requirements.

Frequently Asked Questions:

Q: What surface treatments are available?

A: Options include galvanization, phosphating, or custom coatings upon request.Q: Can I order small-batch prototypes?

A: Yes, we accommodate prototype orders with MOQ starting from 100kg.Q: How do you ensure dimensional consistency?

A: Laser measurement systems perform real-time monitoring during production.Q: What documentation accompanies shipments?

A: All orders include material certificates and ISO compliance documentation.Q: Are custom cross-sections possible?

A: We specialize in non-standard rectangular profiles for unique applications.Q: What's the typical lead time for European orders?

A: Standard production lead time is 25-30 days plus shipping.

Send Inquiry to This Supplier

You May Also Like

-

Seamless Rectangular Steel Pipe for Oil and Gas Sector Pipeline Construction With Enhanced SafetyNegotiableMOQ: 1 Ton

-

Seamless Rectangular Steel Pipe in Various Sizes and Wall Thicknesses for Industrial ApplicationsNegotiableMOQ: 1 Ton

-

Lightweight and Strong Seamless Rectangular Steel Pipe for Easy Handling and Assembly in ManufacturingNegotiableMOQ: 1 Ton

-

Seamless Rectangular Steel Pipe Compatible With Standard Fittings and Welding Processes for VersatilityNegotiableMOQ: 1 Ton

-

Buy Discount Carbon Steel Rectangular Tubing Cold Drawn Rectangular Seamless TubesNegotiableMOQ: 1 Ton

-

1.5*1.5 Inch CHS SHS RHS Hollow Section Pre Galvanized Square GI Tube Rectangular Steel GI Round PipesNegotiableMOQ: 1 Ton

-

A106 Seamless Rectangular Steel Pipe Cold Drawn Black Steel Round Tube for SaleNegotiableMOQ: 1 Ton

-

Wholesale Q550D Carton Rectangular Hollow Section Steel Pipe Seamless TubeNegotiableMOQ: 1 Ton

-

High Quality 100*50*10 Rectangular Steel Pipe Black Square Seamless Cold Drawn TubesNegotiableMOQ: 1 Ton

-

Cold Drawn Seamless Sharp Corner Pipe Q355B 110*45*10 Factory DirectNegotiableMOQ: 1 Ton