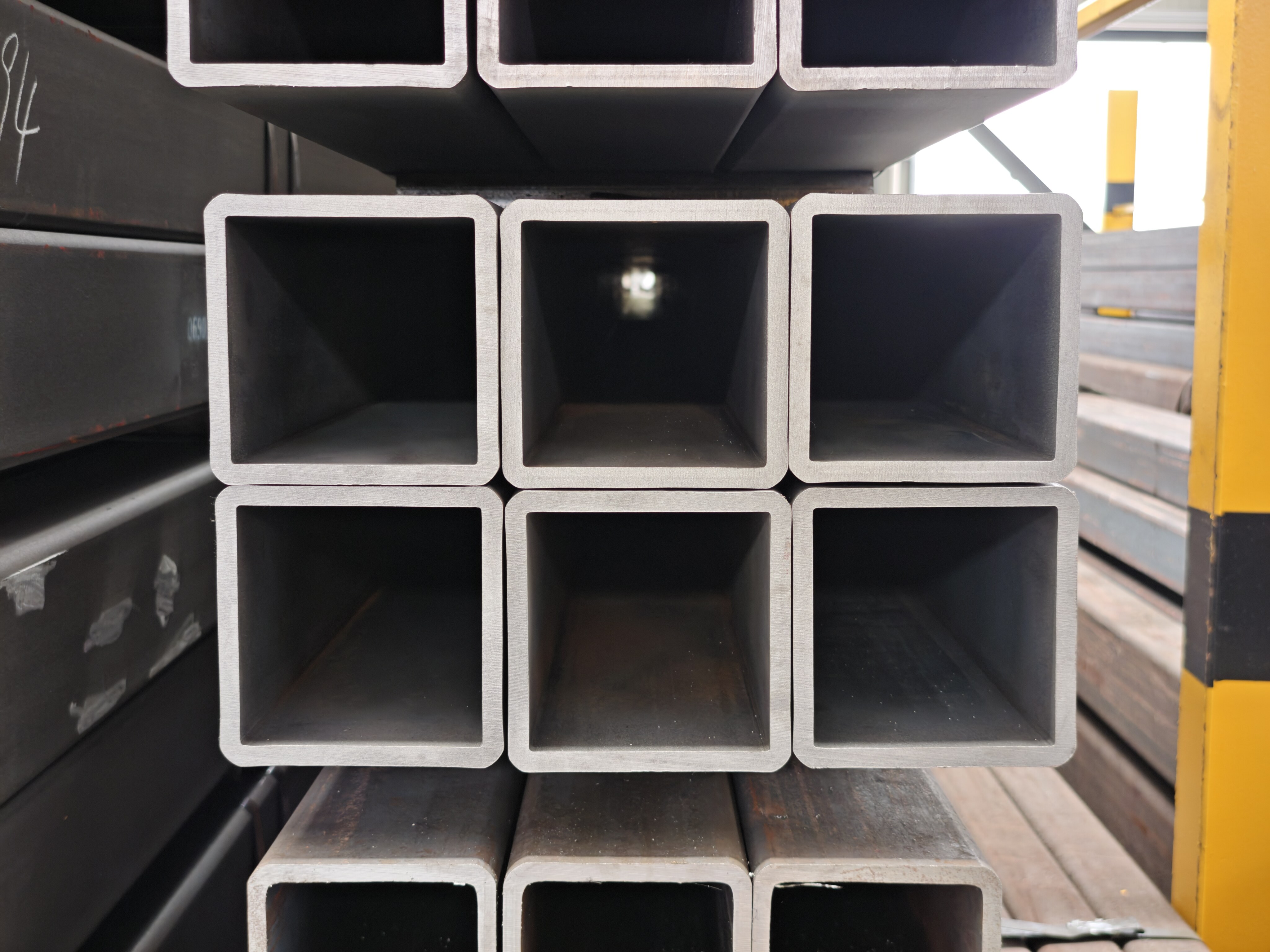

High-Precision Seamless Rectangular Steel Pipe for Engineering Projects and Infrastructure Development

Engineered for excellence in demanding construction environments, our high-precision seamless rectangular steel pipes deliver unmatched structural integrity and dimensional accuracy. Manufactured by Hunan Yige Special Steel using advanced production techniques, these pipes eliminate weak points inherent in welded alternatives. With ISO-certified quality control processes, we ensure every pipe meets rigorous international standards for infrastructure applications where failure is not an option.

The rectangular hollow section design provides superior load-bearing capacity while optimizing material efficiency – a critical advantage for large-scale engineering projects. Our production facility's 5,000-10,000 sqm operational area enables consistent manufacturing of these precision components at commercial volumes.

Key technical advantages include:

Uniform wall thickness throughout pipe length

Elimination of seam weaknesses and stress points

Superior resistance to torsion and bending forces

Enhanced corrosion resistance through controlled composition

Strict adherence to geometric tolerances (±0.1mm)

Common dimensional specifications include:

| Width Range | Height Range | Wall Thickness | Standard Lengths |

|---|---|---|---|

| 20mm - 500mm | 10mm - 300mm | 1.5mm - 25mm | 6m, 12m |

Beyond standard sizes, we offer custom dimensional solutions tailored to specific project requirements. Our rectangular pipes undergo comprehensive quality verification including:

Ultrasonic testing for internal integrity

Dimensional verification with laser measurement

Surface quality inspection

Mechanical property testing (tensile strength: 350-550 MPa)

Chemical composition analysis

Infrastructure applications benefit significantly from these precision components:

Bridge construction: Primary load-bearing elements

Commercial buildings: Structural frameworks and support columns

Transportation infrastructure: Guardrail systems and sign supports

Industrial facilities: Material handling structures and equipment frames

For global engineering teams, we provide logistical solutions to major markets including North America, Europe, and Southeast Asia. Our rectangular pipes ship with protective coatings to prevent transit damage and corrosion.

Frequently Asked Questions

Q: How does seamless manufacturing improve structural performance?

A: Seamless production creates homogeneous material continuity, eliminating weld-related weaknesses that compromise structural integrity under dynamic loads.

Q: What surface treatments are available?

A: Standard mill finish is provided, with optional galvanizing or painting available for corrosion protection in harsh environments.

Q: Can you accommodate non-standard sizes?

A: Yes, our manufacturing capabilities include custom dimensional solutions for specialized engineering requirements.

Q: What documentation accompanies shipments?

A: All shipments include material test certificates, compliance documentation, and commercial invoices.

Q: How do these pipes compare weight-wise to alternative profiles?

A: The rectangular profile offers superior strength-to-weight ratio compared to solid sections, while providing greater rigidity than circular hollow sections of equivalent weight.

Optimize your structural systems with precision-engineered rectangular pipes that deliver reliable performance across decades of service. Contact our engineering team to discuss project-specific requirements and request material samples for evaluation.

Send Inquiry to This Supplier

You May Also Like

-

1.5*1.5 Inch CHS SHS RHS Hollow Section Pre Galvanized Square GI Tube Rectangular Steel GI Round PipesNegotiableMOQ: 1 Ton

-

A106 Seamless Rectangular Steel Pipe Cold Drawn Black Steel Round Tube for SaleNegotiableMOQ: 1 Ton

-

Wholesale Q550D Carton Rectangular Hollow Section Steel Pipe Seamless TubeNegotiableMOQ: 1 Ton

-

High Quality 100*50*10 Rectangular Steel Pipe Black Square Seamless Cold Drawn TubesNegotiableMOQ: 1 Ton

-

Cold Drawn Seamless Sharp Corner Pipe Q355B 110*45*10 Factory DirectNegotiableMOQ: 1 Ton

-

Q460D Carbon Steel Rectangular Seamless Steel PipeNegotiableMOQ: 1 Ton

-

Q355B Seamless Rectangular Steel Pipe Fluid Pipe Hoisting Machinery 6-12 Meters China FactoryNegotiableMOQ: 1 Ton

-

Customized Q390C 160*120*10 Seamless Rectangular Steel Pipe ManufacturersNegotiableMOQ: 1 Ton

-

Hot Selling 500*500*20 Rectangular Steel Pipe Low Carbon Seamless Square TubeNegotiableMOQ: 1 Ton

-

Special Steel Rectangular Steel Pipe Seamless Profile Pipe Cold Drawn Square Round TubesNegotiableMOQ: 1 Ton