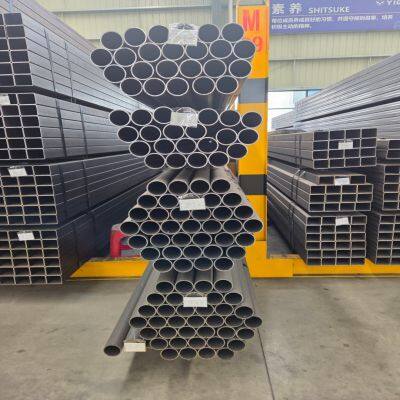

Long-Lasting Welded Round Steel Pipe for Heavy-Duty Machinery and Equipment in Mining Operations

Engineered for extreme mining environments, our welded round steel pipes deliver unmatched durability in heavy-load applications. These precision-crafted components withstand abrasive conditions while maintaining structural integrity, reducing equipment downtime and replacement costs. Manufactured by ISO-certified facilities since 2015, each pipe undergoes rigorous quality validation for consistent performance.

Core Technical Advantages:

- Superior Wear Resistance - Reinforced carbon steel composition extends service life in abrasive material handling

- High-Pressure Tolerance - Seamless welding integrity maintains performance under extreme operational stresses

- Corrosion Defense - Optional protective coatings available for acidic/chemical exposure environments

Standard Specifications Table:

| Parameter | Range |

|---|---|

| Outer Diameter | 21.3mm - 1620mm |

| Wall Thickness | SCH 10 to SCH XXS |

| Tensile Strength | ≥415 MPa |

Custom engineering solutions accommodate specialized requirements including non-standard dimensions, alloy modifications, and proprietary surface treatments. Our 5,000-10,000㎡ manufacturing complex enables large-volume production with batch consistency across global shipments to five continents.

Operational Benefits:

- 30% longer operational lifespan versus industry benchmarks

- Reduced maintenance frequency through impact-resistant construction

- Seamless integration with crushers, conveyors, and drilling systems

Optimize your mining operations with components that endure. Contact our engineering team for material certifications, load-test reports, and volume pricing structures. Global logistics support ensures timely delivery to remote mining sites worldwide.

FAQ Section

Q: What welding methods are employed?

A: We utilize submerged arc welding (SAW) for uniform penetration and consistent joint integrity.

Q: Are custom bend configurations available?

A: Secondary forming services including bending and flanging can be provided upon request.

Q: What packaging protects pipes during transit?

A: Options include plastic end caps, waterproof wrapping, and reinforced bundle strapping.

Q: How does wall thickness affect load capacity?

A: Our engineering team calculates optimal thickness based on your specific pressure requirements.

Q: Do you provide installation guidance?

A: Technical documentation including torque specifications and alignment procedures accompanies shipments.

Send Inquiry to This Supplier

You May Also Like

-

Superior Quality Low Content Alloy Welded Pipe Seamless Carbon Steel PipeNegotiableMOQ: 1 Piece

-

Factory Direct Welded Round Steel Tube Seamless Cold Bending Tube Mental TubeNegotiableMOQ: 1 Piece

-

High Precision Mild Steel Welded Steel Pipe Carbon Steel Pipe Hollow SectionNegotiableMOQ: 1 Piece

-

High Yield Yellow Section Welded Pipe ASTM Cold Bending Round Square Steel PipeNegotiableMOQ: 1 Piece

-

Wholesale Price per Meter QSTE700TM Welded Steel Pipe Seamless Welded Round Steel PipeNegotiableMOQ: 1 Piece

-

Wholesale Price per Meter QSTE600TM Welded Steel Pipe Seamless Welded Round Steel PipeNegotiableMOQ: 1 Piece

-

Wholesale Price per Meter QSTE700TM Welded Steel Pipe Seamless Welded Round Steel PipeNegotiableMOQ: 1 Piece

-

Hot Sale LASW Pipe Weld Steel Pipe Seamless Carbon Steel Tube Manufactures ChinaNegotiableMOQ: 1 Ton

-

High Quality Cheap Straight Seam Pipe LASW Weld Steel Pipe Round Seamless TubeNegotiableMOQ: 1 Ton

-

SSAW Pipe Welded Steel Pipe Large Diameter Carbon Welded Tube Free SampleNegotiableMOQ: 1 Ton