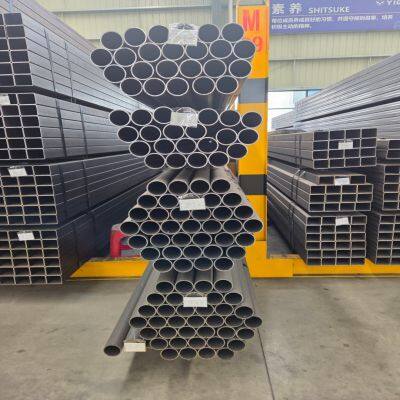

Customizable Welded Round Steel Pipe in Wall Thicknesses 0.5mm to 10mm for Industrial Manufacturing

Precision-engineered for industrial excellence, our customizable welded round steel pipes deliver unmatched versatility in structural and fluid transfer applications. Manufactured by ISO-certified Hunan Yige Special Steel Science Technology Co.,Ltd, these pipes feature wall thickness customization from ultra-thin 0.5mm to heavy-duty 10mm, accommodating diverse pressure requirements across global industrial sectors.

With electric resistance welding (ERW) technology, we ensure consistent wall integrity and dimensional accuracy while maintaining cost efficiency. Our production facility spanning 5,000-10,000㎡ enables large-scale orders without compromising precision.

Core Technical Specifications:

| Parameter | Specification Range |

|---|---|

| Wall Thickness Tolerance | ±10% of nominal thickness |

| Standard Lengths | 3-12 meters (custom cuts available) |

| Tensile Strength | 310-510 MPa (material dependent) |

| Surface Finish Options | Black, Galvanized, Pre-painted |

Industrial Applications Include:

- Structural frameworks for machinery and equipment

- Hydraulic/pneumatic systems requiring pressure-rated conduits

- Conveyor systems and material handling solutions

- Architectural elements requiring curved steel components

- Agricultural equipment manufacturing

Each pipe undergoes non-destructive testing including hydrostatic pressure examinations and visual inspections. Our dual ISO certifications ensure environmental compliance and quality management at every production stage, from raw material selection to final packaging.

Why manufacturers choose our steel pipes:

- Wall thickness precision - Maintains consistent internal diameters for flow systems

- Seam integrity - Welds undergo ultrasonic verification for critical applications

- Corrosion adaptability - Optional zinc coatings (40-120g/㎡) available

- Global compliance - Ships to all continents with documentation packages

With established distribution channels across 15+ global markets including North America, EU nations, and Southeast Asia, we guarantee logistical efficiency. Our engineering team provides technical consultation for:

- Load-bearing calculations

- Material grade selection

- Corrosion protection specifications

Frequently Asked Questions

Q: What pressure ratings do these pipes support?

A: Pressure capacity varies by wall thickness and diameter. Our engineering team provides pressure charts based on your specific dimensions.

Q: Can I get pipes with threaded ends?

A: Yes, threading, grooving, or flanging can be added during manufacturing.

Q: Do you provide material test certificates?

A> Full MTCs including chemical composition and mechanical properties accompany every shipment.

Q: What packaging options are available?

A> Standard bundling with steel straps, or custom wooden crating for international shipments.

Q: How does wall thickness affect weight calculations?

A> Our technical team provides weight-per-meter charts accounting for thickness variations.

Q: Can I order small quantities for prototyping?

A> Yes, we accommodate R&D orders with minimum 100-meter quantities.

Contact our sales engineers today for project-specific quotations. With in-house tooling capabilities and rapid prototyping services, we transform your technical drawings into precision-engineered steel pipe solutions within 4-6 weeks. Request your customized specification sheet detailing tolerance standards, testing protocols, and regional compliance documentation.

Send Inquiry to This Supplier

You May Also Like

-

Factory Direct Welded Round Steel Tube Seamless Cold Bending Tube Mental TubeNegotiableMOQ: 1 Piece

-

High Precision Mild Steel Welded Steel Pipe Carbon Steel Pipe Hollow SectionNegotiableMOQ: 1 Piece

-

High Yield Yellow Section Welded Pipe ASTM Cold Bending Round Square Steel PipeNegotiableMOQ: 1 Piece

-

Wholesale Price per Meter QSTE700TM Welded Steel Pipe Seamless Welded Round Steel PipeNegotiableMOQ: 1 Piece

-

Wholesale Price per Meter QSTE600TM Welded Steel Pipe Seamless Welded Round Steel PipeNegotiableMOQ: 1 Piece

-

Wholesale Price per Meter QSTE700TM Welded Steel Pipe Seamless Welded Round Steel PipeNegotiableMOQ: 1 Piece

-

Hot Sale LASW Pipe Weld Steel Pipe Seamless Carbon Steel Tube Manufactures ChinaNegotiableMOQ: 1 Ton

-

High Quality Cheap Straight Seam Pipe LASW Weld Steel Pipe Round Seamless TubeNegotiableMOQ: 1 Ton

-

SSAW Pipe Welded Steel Pipe Large Diameter Carbon Welded Tube Free SampleNegotiableMOQ: 1 Ton

-

Factory Price Spiral Welded Steel Pipe Oil Line Steel Pipe Welded Carbon SteelNegotiableMOQ: 1 Ton