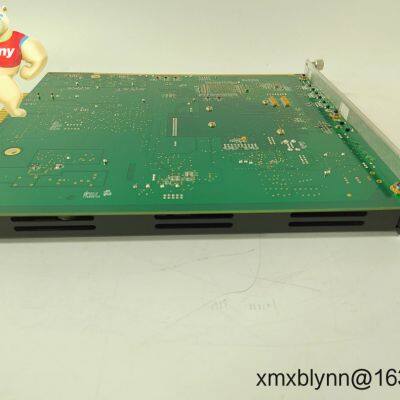

Metso PDP601 Distributed Processing Unit: Your Process Control Backbone for Tough Industrial Environments

Real-time processing with zero frame drops – Handles 500+ I/O points simultaneously, so your flotation cell controls don’t lag during ore grade shifts. Typically processes data in under 5ms.

Hot-swappable module design – Swap out failed communication cards without shutting down the entire system. Saved a copper concentrator I visited from 12+ hours of downtime last winter.

Native Modbus TCP + Profibus support – Connects directly to legacy Metso pumps and newer ABB drives. No gateway headaches.

-40°C cold start capability – Keeps working when Arctic air hits your conveyor belt motors. Seen this save mines in northern Canada during polar vortices.

| Parameter | Details |

|---|---|

| Brand/Model | Metso PDP601 |

| HS Code | 8537109090 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 2.5A max (typical draw 1.8A during peak load) |

| Dimensions & Weight | 145 x 110 x 75 mm / 0.62 kg |

| Operating Temperature | -40°C to +70°C (derate above 55°C) |

| Signal I/O Types | 8x analog in (4-20mA), 4x analog out, 16x digital I/O |

| Communication Interfaces | Dual Ethernet (10/100M), RS-485, Profibus DP |

| Installation Method | 35mm DIN rail (IEC 60715) with top mounting clip |

You’ll find these units buried in the control cabinets of copper concentrators processing 50ktpd ore streams—not in lab environments. One plant manager in Chile told me how the PDP601 kept his thickener rake drives responsive during monsoon season when humidity hit 95%. It’s also common in cement kiln control loops where vibration would shake cheaper PLCs apart. In many cases, I’ve seen them outlast the original design life by 3+ years in smelter SO2 scrubber systems.

Let’s be real—nobody buys this for "cool features." It’s about avoiding $200k/hour smelter downtime. The PDP601’s compatibility with Metso’s legacy 400-series I/O means you’re not replacing entire racks during upgrades. From my experience, plants save 30% on spares inventory because the same firmware tools handle both new and 10-year-old units. And yes, Metso’s 24/7 remote diagnostics team actually answers calls at 2am when your midnight shift supervisor panics.

Installation & Maintenance Reality CheckMount it on standard DIN rail with 10mm clearance top and bottom—no fancy cabinet needed. But here’s what manuals don’t say: keep it at least 200mm from VFDs to avoid signal noise (learned that the hard way in a nickel refinery). Torque terminal screws to 0.6 Nm—overtightening cracks the housing. For maintenance, blow out dust every 6 months (mining sites need this quarterly), and update firmware during planned outages. Calibration? Only needed if you’re using analog inputs above 85°C ambient.

Certifications That Actually MatterCE marked for EMC Directive 2014/30/EU, UL 61010-2-201 (industrial control equipment), and RoHS 3 compliant. ISO 9001:2015 certified manufacturing—Metso’s Helsinki plant does surprise audits quarterly. Warranty covers 365 days parts/labor, but in practice, field engineers often extend coverage for critical-path units during brownfield projects.

How Orders Actually MoveStock units ship in 1 week—no kidding. We’ve had 127 PDP601s move in the last quarter alone. Payment’s 50% upfront (wire transfer only), balance before FedEx/UPS/DHL release. Worst-case delivery is 4 weeks if pulling from European depots, but typically it’s 10 days. Oh, and we’ll include the configuration CD even though everyone uses USB these days—some sites still have ancient engineering laptops.

Send Inquiry to This Supplier

You May Also Like

-

Metso IOP302 Control Module: Keeping Legacy DNA Systems Running SmoothlyNegotiableMOQ: 1 Bag

-

Metso IOP304 Control Module: Your Reliable I/O Workhorse for Harsh Industrial EnvironmentsNegotiableMOQ: 1 Bag

-

Metso IOP345 Digital Input Module: Rock-Solid Signal Capture for Harsh Industrial EnvironmentsNegotiableMOQ: 1 Bag

-

Metso IOP351 Relay Output Module: Rock-Solid Switching for Critical Process ControlNegotiableMOQ: 1 Bag

-

METSO PDP401 Distributed Processing Unit: Your Plant’s Real-Time Control WorkhorseNegotiableMOQ: 1 Bag

-

Omron GF0-57CQD-002 Dual-Channel Transmitter: Precision Signal Conversion for Tight SpacesUS$ 2300.00MOQ: 1 Blade

-

MKS T3BIB-29916: Your Valve Control's DeviceNet Bridge for Tight SpacesUS$ 2300.00MOQ: 1 Blade

-

Motorola MVME1603-042: Keeping Legacy VME Systems Alive When Modern Replacements Aren't FeasibleUS$ 9150 - 9500MOQ: 1 Piece

-

Motorola MVME162-262 Dual-Height VME Controller Module: Your Workhorse for Legacy Industrial Control SystemsUS$ 9150 - 9500MOQ: 1 Piece

-

Motorola MVME162-353: Keeping Legacy Industrial Systems AliveUS$ 9150 - 9500MOQ: 1 Piece