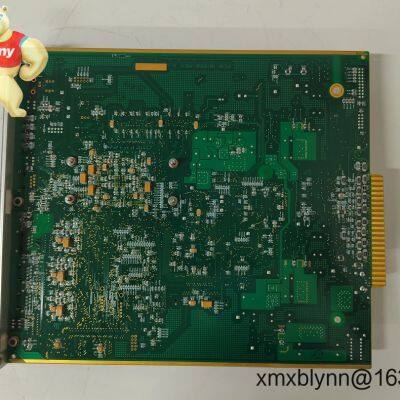

METSO PDP401 Distributed Processing Unit: Your Plant’s Real-Time Control Workhorse

Decentralized intelligence – Processes sensor data right at the machine level. You might notice faster response times on conveyor jams since signals don’t ping-pong back to the main control room.

Seamless Metso DNA integration – Typically plugs straight into existing Metso automation ecosystems. A client in Chile avoided weeks of reprogramming during their smelter upgrade because of this.

Vibration-resistant design – Survives crusher operations where standard PLCs conk out. In many cases, it’s running smoothly at 10g vibration levels that’d make other units cry.

Hot-swap capability – Replace faulty modules without killing production. One paper mill tech told me he swapped a comms card during a grade changeover – saved them 8 hours of downtime.

| Parameter | Specification |

|---|---|

| Brand/Model | METSO PDP401 |

| HS Code | 85371090 (Programmable controllers) |

| Power Requirements | 24 VDC ±15%, 2.5A max (typical draw 1.8A) |

| Dimensions & Weight | 120 x 100 x 75 mm / 0.65 kg |

| Operating Temperature | -20°C to +60°C (no derating up to 50°C) |

| Signal I/O Types | Digital (24V), Analog (4-20mA, ±10V), RTD/thermocouple |

| Communication Interfaces | Dual Modbus TCP, Profibus DP, optional Fiber optic |

| Installation Method | DIN rail (35mm), IP20 rating |

Think mineral processing plants where crushers vibrate constantly, or paper machines needing millisecond response on steam valves. I’ve seen it excel in wastewater treatment too – one facility in Ohio uses it to manage sludge pumps during storm surges when their main system’s busy with inflow calculations. It’s not for simple conveyor lines; you’ll want this when localized decision-making prevents cascading failures.

Sure, cheaper PLCs exist, but the PDP401’s value shows up in maintenance logs. Its diagnostics cut troubleshooting time by half – one maintenance lead showed me logs where it flagged a failing thermocouple 3 days before it would’ve caused a reactor shutdown. Compatibility with legacy Metso systems means no costly gateway hardware. And honestly? The 365-day warranty matters when you’re budgeting for a 10-year asset lifecycle.

Installation & Maintenance Reality CheckMount it on standard DIN rail in a NEMA 12 cabinet – no fancy shock absorption needed unless you’re next to a ball mill. Leave 50mm clearance above/below for airflow; I’ve seen units overheat when crammed beside VFDs. Safety-wise, always disconnect 24V power before swapping modules (that brownout protection won’t save you from live terminals). For maintenance: quarterly visual checks for dust buildup, calibrate analog inputs annually, and push firmware updates during planned outages – Metso’s update process takes about 8 minutes. Skip the compressed air cleaning; it drives dust into connectors.

Ordering & GuaranteesWarranty: 365 days from commissioning (covers component failures, not improper installation)

Delivery: 1 week for in-stock units, max 4 weeks for configured orders

Payment: 50% advance, balance before shipping

Shipping: FedEx/UPS/DHL with real-time tracking – no freight brokers

Quality That Holds UpCE marked per 2014/30/EU, UL 61010-1 certified, and ISO 13849-1 compliant for functional safety. RoHS 3 compliant since 2020 revisions. The conformal coating on PCBs? That’s why units survive coastal pulp mills where salt air eats cheaper controllers. One caution though – avoid installing near 500Hz+ VFDs without shielded conduit; I’ve seen comms glitches in two installations where this was overlooked.

Send Inquiry to This Supplier

You May Also Like

-

METSO DPU-MR Processing Unit: The No-Nonsense Control Brain for Aggregate PlantsNegotiableMOQ: 1 Bag

-

Metso IOP302 Control Module: Keeping Legacy DNA Systems Running SmoothlyNegotiableMOQ: 1 Bag

-

Metso IOP304 Control Module: Your Reliable I/O Workhorse for Harsh Industrial EnvironmentsNegotiableMOQ: 1 Bag

-

Metso IOP345 Digital Input Module: Rock-Solid Signal Capture for Harsh Industrial EnvironmentsNegotiableMOQ: 1 Bag

-

Metso IOP351 Relay Output Module: Rock-Solid Switching for Critical Process ControlNegotiableMOQ: 1 Bag

-

Omron GF0-57CQD-002 Dual-Channel Transmitter: Precision Signal Conversion for Tight SpacesUS$ 2300.00MOQ: 1 Blade

-

MKS T3BIB-29916: Your Valve Control's DeviceNet Bridge for Tight SpacesUS$ 2300.00MOQ: 1 Blade

-

Motorola MVME1603-042: Keeping Legacy VME Systems Alive When Modern Replacements Aren't FeasibleUS$ 9150 - 9500MOQ: 1 Piece

-

Motorola MVME162-262 Dual-Height VME Controller Module: Your Workhorse for Legacy Industrial Control SystemsUS$ 9150 - 9500MOQ: 1 Piece

-

Motorola MVME162-353: Keeping Legacy Industrial Systems AliveUS$ 9150 - 9500MOQ: 1 Piece