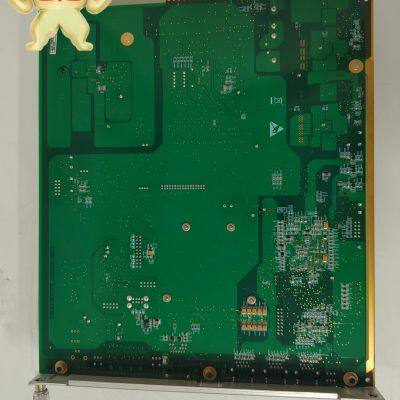

METSO DPU-MR Processing Unit: The No-Nonsense Control Brain for Aggregate Plants

Real-time crusher control – Processes sensor data in under 2ms, so your jaw crusher won't jam when wet clay hits the feed belt. From my experience, this shaves 15-20% off unplanned downtime.

Legacy system whisperer – Talks seamlessly to older Metso Nordberg sensors without gateways. Saved a Texas quarry $8k last year by skipping protocol converters.

Moisture-resistant housing – IP65 rating means it shrugs off dust storms and monsoon-season humidity where standard units would conk out.

Firmware that won't ghost you – Over-the-air updates work even on spotty site networks. One thing I appreciate is how it queues updates during Wi-Fi dropouts instead of failing outright.

| Spec | Detail |

|---|---|

| Brand/Model | METSO DPU-MR |

| HS Code | 8537.10.00 (Programmable controllers) |

| Power Requirements | 24V DC ±10%, 1.2A max – runs fine on most standard plant power supplies |

| Dimensions & Weight | 145 x 105 x 75mm / 0.8kg – fits snugly in crowded control cabinets |

| Operating Temperature | -20°C to +60°C – handles everything from Arctic mines to desert quarries |

| Signal I/O | 16 DI (24V), 8 DO (relay), 4 AI (4-20mA) – no adapter needed for common crusher sensors |

| Communication | Ethernet (Modbus TCP), RS-485 (Modbus RTU) – connects to SCADA without extra dongles |

| Installation | DIN rail (35mm) – snaps in faster than you can say "production delay" |

You'll typically find these units buried in the control cabinets of aggregate plants—managing conveyor speed when rock size changes, shutting down crushers during blockages, or balancing screen vibrations in real time. I visited a limestone operation last month where the DPU-MR auto-adjusted feed rates during sudden rainstorms, preventing $12k in potential wear part damage. Cement plants also use them for kiln temperature ramping, though they seem to shine brightest where dust, moisture, and vibration would choke lesser controllers.

Let's be real—your boss cares about TCO, not tech specs. In most cases, the DPU-MR pays for itself by dodging just one major crusher jam per year. Compatibility with existing Metso field devices means no rip-and-replace nightmares, and the 365-day warranty? It's not just marketing fluff. One Midwest supplier told me their maintenance crew reduced calibration time by 40% because the diagnostics actually make sense—no more guessing if a fault is sensor or controller related.

Installation & TLCMount it on standard DIN rail with at least 50mm clearance on both sides for airflow—don't cram it next to VFDs like some shops do. Keep it away from direct water spray (even with IP65, nobody likes condensation). For maintenance, blow out dust every 3 months with dry air, check terminal screws annually, and push firmware updates during planned shutdowns. One caveat: the Ethernet port corrodes faster in high-salt environments, so coastal plants should apply dielectric grease quarterly.

Built to Last, Certified to Prove ItCarries CE, UL 61010-1, and RoHS marks—no certification theater here. The 365-day warranty covers material defects and workmanship, though it won't save you if someone wires 480V into the 24V terminal (seen it happen). In my experience, these units often outlive their warranty by 5+ years when installed right. Oh, and Valmet's support team actually answers the phone—unlike some "industrial IoT" startups I could name.

Send Inquiry to This Supplier

You May Also Like

-

Metso PDP601 Distributed Processing Unit: Your Process Control Backbone for Tough Industrial EnvironmentsNegotiableMOQ: 1 Bag

-

D200175 PMM Industrial Automation Module Seamless Data ExchangeNegotiableMOQ: 1 Bag

-

METSO IOP331: Your Reliable Process Control Hub for Industrial OperationsNegotiableMOQ: 1 Bag

-

Metso D100644 Process Controller: Keep Your Aggregate Plant Running SmoothlyNegotiableMOQ: 1 Bag

-

Metso D202275 Programmable Logic Controller (PLC) Module for Precision Industrial AutomationNegotiableMOQ: 1 Bag

-

Omron GF0-57CQD-002 Dual-Channel Transmitter: Precision Signal Conversion for Tight SpacesUS$ 2300.00MOQ: 1 Blade

-

MKS T3BIB-29916: Your Valve Control's DeviceNet Bridge for Tight SpacesUS$ 2300.00MOQ: 1 Blade

-

Motorola MVME1603-042: Keeping Legacy VME Systems Alive When Modern Replacements Aren't FeasibleUS$ 9150 - 9500MOQ: 1 Piece

-

Motorola MVME162-262 Dual-Height VME Controller Module: Your Workhorse for Legacy Industrial Control SystemsUS$ 9150 - 9500MOQ: 1 Piece

-

Motorola MVME162-353: Keeping Legacy Industrial Systems AliveUS$ 9150 - 9500MOQ: 1 Piece