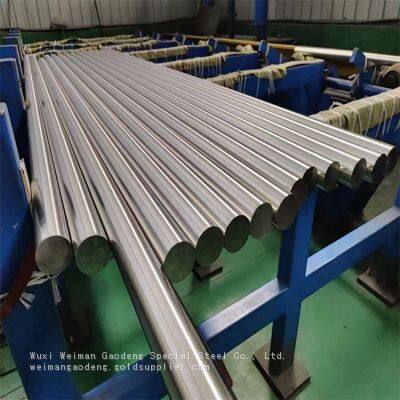

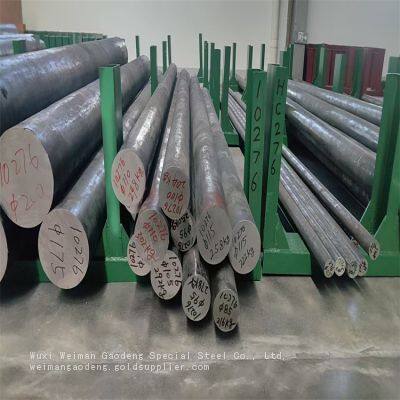

Premium Inconel 600 Alloy Bar N06600 High Temperature Nickel Chromium Round Bar Stock

Engineered for extreme environments, our Inconel 600 alloy round bars deliver unmatched performance in high-temperature and corrosive applications. As a specialized manufacturer, we provide premium-grade N06600 nickel-chromium bars that maintain structural integrity under thermal stress while resisting oxidation and carburization.

This versatile nickel-based superalloy offers exceptional resistance to chloride-ion stress-corrosion cracking and corrosion by various acids and alkalis. With its unique combination of high strength and workability, Inconel 600 is the material of choice for critical components in demanding industrial processes.

Key Technical Advantages:

- Superior oxidation resistance in continuous service up to 2000°F (1093°C)

- Excellent chloride stress-corrosion cracking resistance

- Good mechanical properties maintained across temperature extremes

- Outstanding resistance to alkalis and organic compounds

- Low gas content and vacuum compatibility for specialized applications

Standard Chemical Composition (% by weight):

| Element | Min | Max |

|---|---|---|

| Nickel (Ni) | 72.0 | - |

| Chromium (Cr) | 14.0 | 17.0 |

| Iron (Fe) | 6.0 | 10.0 |

| Carbon (C) | - | 0.15 |

| Manganese (Mn) | - | 1.0 |

Typical room temperature mechanical properties:

- Tensile Strength: 550-760 MPa

- Yield Strength (0.2% offset): 240-410 MPa

- Elongation: 30-55%

Our manufacturing capabilities allow for customized solutions including special diameters, lengths up to 6 meters, and various surface finishes to meet specific application requirements. All material is supplied with mill test certificates verifying chemical composition and mechanical properties.

Industrial Applications Include:

- Heat treatment furnace components and fixtures

- Chemical and petrochemical processing equipment

- Nuclear reactor components

- Thermocouple protection tubes

- Aerospace engine components

- Pollution control systems

Backed by our specialized production facility in Wuxi and extensive export experience across global markets, we ensure reliable supply of premium Inconel 600 round bars. Our quality assurance protocols guarantee material traceability and consistency batch-to-batch. Contact our technical team today to discuss your project specifications or request material certifications.

Frequently Asked Questions

Q: What makes Inconel 600 suitable for high-temperature applications?

A: Its high nickel content provides exceptional resistance to oxidation and scaling at temperatures up to 2000°F, while maintaining good mechanical strength. The alloy forms a protective chromium oxide layer that prevents further degradation.

Q: Can you supply Inconel 600 bars in custom sizes?

A: Yes, we offer diameter customization from 5mm to 300mm and can cut to specified lengths. Special tolerances and surface finishes are available upon request.

Q: What documentation accompanies your Inconel 600 products?

A: All shipments include mill test certificates (MTC) verifying chemical composition and mechanical properties. Additional documentation such as material traceability reports can be provided.

Q: How does Inconel 600 perform in corrosive environments?

A: It offers excellent resistance to freshwater, steam, alkalis, and many organic compounds. However, performance varies depending on specific corrosive media and temperature conditions.

Q: What processing methods do you use for these bars?

A: We produce bars through hot working processes (forging, rolling) followed by annealing to achieve the desired mechanical properties. Secondary processing like turning or polishing is available.

Q: What is your standard packaging for international shipments?

A: We use wooden crates with waterproof wrapping to prevent corrosion during transit. Special packaging requirements can be accommodated.

Send Inquiry to This Supplier

You May Also Like

-

ASME SB-166 Certified N06600 Round Bar | Heat-Resistant Inconel 600 Alloy Bars for Industrial UseNegotiableMOQ: 10 Kilograms

-

ASTM B446 Compliant Inconel 625 Superalloy Bar | High-Strength Corrosion-Resistant Bar StockNegotiableMOQ: 10 Kilograms

-

ASME SB-446 Certified N06625 Round Bar | Weldable High-Performance Inconel 625 Alloy BarsNegotiableMOQ: 10 Kilograms

-

ASTM B637 Compliant Inconel 718 Premium Round Bar | High-Temperature Strength & Fatigue-Resistant BarsNegotiableMOQ: 10 Kilograms

-

ASME SB-637 Certified N07718 Round Bar | Creep-Resistant Machinable Inconel 718 Alloy BarsNegotiableMOQ: 10 Kilograms

-

Premium Inconel 718 Forgings - High-Temp Strength, Creep Resistant | Aerospace-Grade Superalloy ComponentsNegotiableMOQ: 1 Piece

-

Heavy-Duty Inconel 625 Forgings - Oxidation Proof, 1090°C Stability | Industrial Superalloy ForgingsNegotiableMOQ: 1 Piece

-

Industrial Hastelloy X Forgings - 1200°C Resistance, Combustor-Grade | High-Temp Superalloy PartsNegotiableMOQ: 1 Piece

-

High-Creep Haynes 282 Forgings - Power Gen Turbines, 800°C Stability | Premium Superalloy ComponentsNegotiableMOQ: 1 Piece

-

Inconel 600 Forgings - Steam Oxidation Resistance, Heat Exchangers | Industrial Superalloy PartsNegotiableMOQ: 1 Piece