High-Creep Haynes 282 Forgings - Power Gen Turbines, 800°C Stability | Premium Superalloy Components

Product Details: High-Quality Forgings for Global Industrial Applications

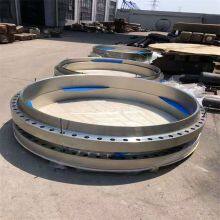

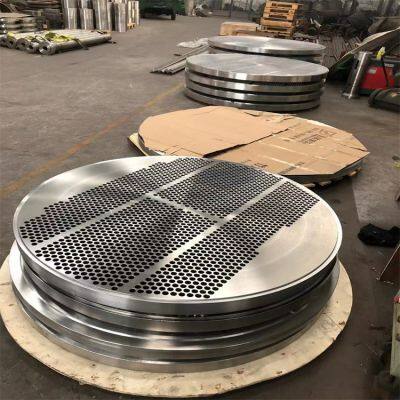

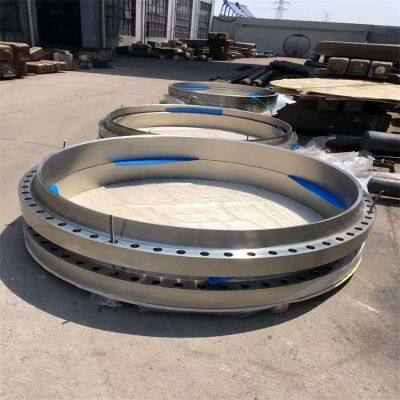

We specialize in manufacturing precision-forged components tailored for extreme industrial environments, covering superalloy forgings, nickel-based alloy forgings, and custom forged parts. Engineered to meet rigorous international standards, our products deliver exceptional performance in high temperatures, corrosive conditions, and heavy-load scenarios—ideal for aerospace, oil & gas, chemical processing, and power generation sectors worldwide.

Core Advantages

• Premium Materials: Crafted from high-purity alloys (Inconel, Hastelloy, Monel, Incoloy, etc.) with strict composition control, ensuring consistent mechanical properties (tensile strength 550–1450 MPa) and resistance to oxidation, corrosion, and creep.

• Extreme Environment Adaptability:

◦ High-Temp Stability: Withstand continuous service temperatures up to 1200°C (e.g., Inconel 601, Hastelloy X), making them suitable for furnaces, gas turbines, and jet engines.

◦ Corrosion Resistance: Resist harsh chemicals (sulfuric acid, hydrochloric acid), saltwater, and sulfide environments (e.g., Hastelloy C276, Monel 400), ideal for chemical reactors and marine equipment.

◦ Mechanical Durability: Excellent creep resistance, thermal fatigue resistance, and high strength-to-weight ratio, ensuring long service life in heavy-load applications (e.g., aerospace turbine disks, oil well downhole tools).

• Precision Forging Technology: Advanced hot/cold forging processes achieve tight tolerances (±0.02mm) and dense microstructures, enhancing structural integrity. Customizable in sizes (thickness 5–1000mm, length up to 12m) to fit unique project requirements.

Key Materials & Applications

Category | Main Alloys | Core Properties | Typical Applications |

Superalloy Forgings | Inconel 718/625/600, Hastelloy X, Haynes 282 | High-temp strength, creep resistance, oxidation proof | Aerospace turbine disks, jet engine blades, gas turbine combustors, industrial furnaces |

Nickel-Based Alloy Forgings | Monel 400/K-500, Incoloy 825/800H, Hastelloy C276 | Corrosion resistance, saltwater proof, acid resistance | Marine valves, chemical tanks, oil well downhole tools, pharmaceutical reactors |

Custom Forged Components | Alloy-specific forgings (per client specs) | Tailored strength, wear resistance, or thermal stability | Power generation equipment, structural aerospace parts, heavy machinery components |

Quality & Certification

• Compliance with Global Standards: Meet ASTM (B564, B637), ASME (SB336, SB564), ISO 9001, and NADCAP requirements, with material certificates (MTR) and third-party testing reports (UT, MT, RT) available.

• Rigorous Quality Control: Each forging undergoes strict inspection—from raw material verification to final dimensional checks—ensuring zero defects and consistent performance.

Customization & Support

• Flexible Specifications: Customizable in size (thickness 5–1000mm, length up to 12m), surface finish (pickled, polished, or coated), and heat treatment (annealing, aging) to match your exact needs.

• Global Service: Offer OEM/ODM solutions, with multilingual technical support, prompt lead times, and flexible logistics (FOB, CIF) to major ports worldwide. Documentation includes commercial invoices, packing lists, and customs declarations for seamless cross-border shipping.

Whether you need high-temp superalloy forgings for aerospace turbines or corrosion-resistant nickel-based forgings for chemical tanks, we deliver reliable, long-lasting solutions. Contact us today for a tailored quote and technical consultation.

Your Trusted Partner for Forgings in Extreme Environments—Globally Delivered.

Send Inquiry to This Supplier

You May Also Like

-

Nickel Alloy Rod/Bar High Wear-resistant and High Toughness AlloyNegotiableMOQ: 1 Piece

-

ASTM B164 Certified Monel 400 Round Bar | Corrosion-Resistant Nickel-Copper Alloy Bar StockNegotiableMOQ: 1 Piece

-

Monel Round Bars Monel Rod Monel 400 N04400 Bars and RodsNegotiableMOQ: 10 Kilograms

-

N05500 10mm 20mm Monel 400 Monel K500 Nickel Alloy Bar With Good Price Per KgNegotiableMOQ: 10 Kilograms

-

Monel Price Monel 400/Monel K500, High Quality Monel Price, Monel K500NegotiableMOQ: 10 Kilograms

-

Factory Direct Sales Nickel Alloy Bar Monel 400/Monel K500 Copper NickelNegotiableMOQ: 10 Kilograms

-

Monel 400 Round Bar Stock & Supplier Nickel Round Bar 400 MonelNegotiableMOQ: 10 Kilograms

-

High Temperature Alloy MonelK-500/N05500/Monel400 Bars, Pipes and Strips Price Per KgNegotiableMOQ: 10 Kilograms

-

Monel Alloy Monel 400 (UNS N04400) for Corrosion ResistanceNegotiableMOQ: 10 Kilograms

-

Corrosion Resistant Nickel Alloy Monel K-500 Factory Price Nickle Alloy Monel 404 Round BarNegotiableMOQ: 10 Kilograms