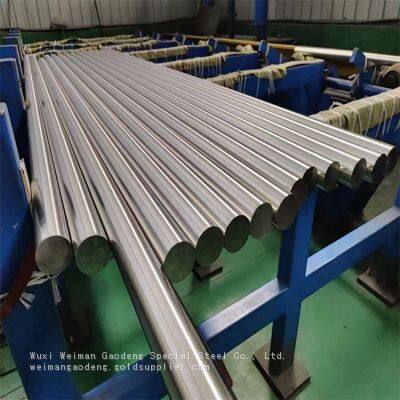

Custom Diameter Options of Inconel Alloy Bar Such as 1/4" to 2" With Models Like Inconel 601

Wuxi Weiman Gaodeng Special Steel delivers precision-crafted Inconel alloy bars with fully customizable diameter options ranging from 1/4" to 2", including popular grades like Inconel 601. Engineered for extreme environments, these nickel-chromium superalloy bars maintain structural integrity in temperatures exceeding 2000°F while resisting oxidation, carburization, and corrosive media.

Our manufacturing expertise allows exact diameter specifications to match your technical drawings, eliminating costly secondary machining. With ISO-compliant quality systems (certificate available upon request), we ensure dimensional accuracy within ±0.001" tolerance and provide full traceability documentation.

Core advantages include:

- ✓ Reduced lead times through in-house diameter customization

- ✓ Material certification with each shipment

- ✓ Optimized cost-efficiency by minimizing material waste

- ✓ Multi-port shipping flexibility from Shanghai/Ningbo

Typical mechanical properties for standard Inconel 601 bars:

| Diameter Range | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| 1/4" - 1" | ≥ 655 MPa | ≥ 240 MPa | ≥ 30% |

| 1" - 2" | ≥ 620 MPa | ≥ 220 MPa | ≥ 25% |

Our production capabilities include multiple surface finish options to suit different application requirements:

- Peeled finish for general industrial use

- Cold drawn for enhanced dimensional precision

- Centerless ground for tight-tolerance applications

- Polished for corrosion-critical environments

With over 100 employees operating from our 3,000m² Jiangsu facility, we maintain strict process controls from alloy melting to final inspection. All bars undergo ultrasonic testing for internal integrity and eddy current examination for surface defects.

Frequently Asked Questions:

Q: What's the minimum order quantity for custom diameters?

A: MOQ starts at 100kg for standard diameters, with volume discounts available. Contact us for project-specific pricing.

Q: Can you supply other Inconel grades besides 601?

A: Yes, we regularly produce bars in grades 625, 718, X-750, and 800 series. Submit your specification for confirmation.

Q: What documentation accompanies shipments?

A: All orders include Material Test Reports certifying chemical composition and mechanical properties per ASTM B166.

Q: Do you offer cutting services?

A: Yes, we provide precision cutting to length with options for bundle packaging or individual protection.

Q: How do you handle international shipping?

A: We ship EXW from Shanghai, Ningbo or Lianyungang ports with FOB/CIF terms available. Export documentation is handled in-house.

Q: What's the production lead time?

A: Standard diameters ship in 7-10 days. Custom diameters require 15-20 days depending on quantity and specifications.

Q: Can I request special packaging?

A: Absolutely. We offer weatherproof wooden crates, PVC wrapping, or custom packaging solutions upon request.

Backed by US$10M annual export experience across 15 global markets, Wuxi Weiman Gaodeng combines technical expertise with responsive customer support. Our engineers will review your diameter requirements and recommend optimal material solutions for your application.

Submit your technical drawings today for a competitive quotation on custom-sized Inconel bars. Contact our export team to discuss project specifications or request material certification samples.

Send Inquiry to This Supplier

You May Also Like

-

ASME SB-446 Certified N06625 Round Bar | Weldable High-Performance Inconel 625 Alloy BarsNegotiableMOQ: 10 Kilograms

-

ASTM B637 Compliant Inconel 718 Premium Round Bar | High-Temperature Strength & Fatigue-Resistant BarsNegotiableMOQ: 10 Kilograms

-

ASME SB-637 Certified N07718 Round Bar | Creep-Resistant Machinable Inconel 718 Alloy BarsNegotiableMOQ: 10 Kilograms

-

Premium Inconel 718 Forgings - High-Temp Strength, Creep Resistant | Aerospace-Grade Superalloy ComponentsNegotiableMOQ: 1 Piece

-

Heavy-Duty Inconel 625 Forgings - Oxidation Proof, 1090°C Stability | Industrial Superalloy ForgingsNegotiableMOQ: 1 Piece

-

Industrial Hastelloy X Forgings - 1200°C Resistance, Combustor-Grade | High-Temp Superalloy PartsNegotiableMOQ: 1 Piece

-

High-Creep Haynes 282 Forgings - Power Gen Turbines, 800°C Stability | Premium Superalloy ComponentsNegotiableMOQ: 1 Piece

-

Inconel 600 Forgings - Steam Oxidation Resistance, Heat Exchangers | Industrial Superalloy PartsNegotiableMOQ: 1 Piece

-

Inconel X-750 Forgings - Spring Applications, 700°C Strength | High-Fatigue Superalloy ComponentsNegotiableMOQ: 1 Piece

-

Haynes 188 Forgings - Oxidation Resistant, Gas Turbine Combustors | Industrial Superalloy ForgingsNegotiableMOQ: 1 Piece