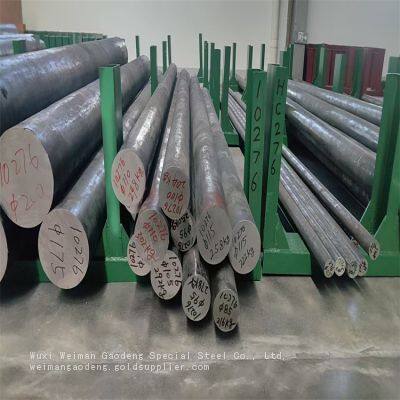

Superior Durability Inconel Alloy Bar With Inconel X-750 for Chemical Processing Equipment

Engineered for extreme environments, our Inconel X-750 alloy bars deliver unmatched durability in aggressive chemical processing applications. These nickel-chromium superalloy rods maintain structural integrity under continuous exposure to corrosive media and high-temperature operations up to 1300°F (700°C). Manufactured under strict quality control, they provide reliable performance where standard materials would rapidly degrade.

Wuxi Weiman Gaodeng Special Steel specializes in producing premium Inconel bars that significantly extend equipment service life in critical industries. Our vertically integrated manufacturing process ensures precise metallurgical properties and dimensional consistency across all product batches.

Key Technical Specifications:

| Property | Typical Value | Testing Standard |

|---|---|---|

| Yield Strength (0.2% Offset) | 690 MPa | ASTM E8 |

| Elongation in 2" | ≥ 25% | ASTM E8 |

| Hardness (Rockwell B) | 88-96 HRB | ASTM E18 |

| Density | 8.28 g/cm³ | N/A |

Operational Advantages in Chemical Environments:

Stress corrosion cracking resistance in chloride-containing solutions

Exceptional oxidation resistance in combustion atmospheres

Retention of mechanical properties during thermal cycling

Low corrosion rates in sulfuric, nitric, and phosphoric acids

Reduced maintenance requirements for valves, reactors, and heat exchangers

Our manufacturing capabilities include custom processing options such as centerless grinding, straightening, and ultrasonic testing. With an annual export volume exceeding US$5 million to global markets including North America and Europe, we maintain sufficient stock for immediate shipment through major Chinese ports.

Frequently Asked Questions:

Q: What distinguishes Inconel X-750 from other nickel alloys?

A: X-750 contains aluminum and titanium additions that create precipitation-hardening capabilities, providing enhanced strength retention at elevated temperatures compared to non-age-hardenable alloys.

Q: Can these bars be welded to other materials?

A: While possible with specialized techniques, we recommend consultation with our technical team for specific welding procedure recommendations to avoid stress-related failures.

Q: What certification documentation accompanies shipments?

A> All material ships with Mill Test Reports certifying chemical composition and mechanical properties according to customer specifications.

Q: What is the typical lead time for custom diameters?

A: Standard sizes ship within 7 days; non-standard diameters require 3-4 weeks for production and quality verification.

Q: How does this alloy perform in sour gas environments?

A: X-750 demonstrates excellent resistance to sulfide stress cracking in H₂S-containing environments when properly heat treated.

Leverage our specialized metallurgical expertise to solve your most challenging corrosion problems. With ISO-compliant manufacturing facilities covering 1,000-3,000 square meters and a dedicated quality team, we ensure every bar meets rigorous industry standards. Contact our technical sales department for material selection guidance and custom quotation requests.

Send Inquiry to This Supplier

You May Also Like

-

Premium Inconel 600 Alloy Bar N06600 High Temperature Nickel Chromium Round Bar StockNegotiableMOQ: 10 Kilograms

-

Certified Inconel Alloy Bar for Aerospace Fasteners Featuring N06600 and Inconel 740H High Temperature BarNegotiableMOQ: 10 Kilograms

-

Custom Diameter Options of Inconel Alloy Bar Such as 1/4" to 2" With Models Like Inconel 601NegotiableMOQ: 10 Kilograms

-

ASTM B164 Certified Monel 400 Round Bar | Corrosion-Resistant Nickel-Copper Alloy Bar StockNegotiableMOQ: 10 Kilograms

-

ASME B865 Compliant N05500 Bar Stock | Marine-Grade Corrosion-Resistant Monel K-500 Alloy BarsNegotiableMOQ: 10 Kilograms

-

ASTM B166 Compliant Inconel 600 Bar Stock | High-Temperature & Oxidation-Resistant Nickel-Chromium BarsNegotiableMOQ: 10 Kilograms

-

ASME SB-166 Certified N06600 Round Bar | Heat-Resistant Inconel 600 Alloy Bars for Industrial UseNegotiableMOQ: 10 Kilograms

-

ASTM B446 Compliant Inconel 625 Superalloy Bar | High-Strength Corrosion-Resistant Bar StockNegotiableMOQ: 10 Kilograms

-

ASME SB-446 Certified N06625 Round Bar | Weldable High-Performance Inconel 625 Alloy BarsNegotiableMOQ: 10 Kilograms

-

ASTM B637 Compliant Inconel 718 Premium Round Bar | High-Temperature Strength & Fatigue-Resistant BarsNegotiableMOQ: 10 Kilograms