High-temperature Stable Hastelloy Plate N10665 Ideal for Aerospace Components Requiring Durability

Experience unparalleled performance with our high-temperature stable Hastelloy N10665 plates, engineered to withstand extreme conditions in aerospace applications. These nickel-molybdenum alloy plates deliver exceptional corrosion resistance and structural integrity under thermal stress exceeding 1000°C. Manufactured through precision rolling and heat treatment processes, they provide reliable solutions for mission-critical components where failure is not an option.

The unique composition of Hastelloy N10665 offers superior durability against oxidizing and reducing environments, making it the material of choice for jet engine parts, turbine components, and exhaust systems. With customizable dimensions and surface finishes, these plates adapt to your specific aerospace design requirements while maintaining dimensional stability across thermal cycles.

Key Technical Specifications:

| Property | Value | Testing Standard |

| Tensile Strength | ≥ 690 MPa | ASTM E8 |

| Yield Strength (0.2% offset) | ≥ 310 MPa | ASTM E8 |

| Elongation in 50mm | ≥ 40% | ASTM E8 |

| Density | 9.24 g/cm³ | ASTM B311 |

Performance Advantages:

Thermal Stability: Maintains mechanical properties from cryogenic temperatures to 1093°C

Corrosion Resistance: Excellent resistance to hydrochloric, sulfuric and phosphoric acids

Stress Corrosion Cracking Immunity: Superior performance in chloride-containing environments

Fabrication Flexibility: Suitable for welding, forming, and machining operations

Oxidation resistance in air up to 1177°C for extended service life

Our manufacturing facility utilizes vacuum induction melting and electroslag remelting processes to achieve homogeneous microstructures with minimal inclusions. Each plate undergoes ultrasonic testing and dimensional verification to ensure compliance with aerospace quality requirements. Production batches include full traceability documentation, including heat number and material test reports.

For specialized aerospace projects, we offer custom solution annealing treatments and surface conditioning services to meet specific performance criteria. Technical consultation is available to assist with material selection and application engineering.

Frequently Asked Questions:

Q: What distinguishes Hastelloy N10665 from other nickel alloys?

A: N10665 exhibits superior corrosion resistance in reducing chemical environments due to its high molybdenum content (26-30%), while maintaining excellent fabricability. Unlike many high-temperature alloys, it doesn't require precipitation hardening treatments.

Q: Can these plates be used in rocket propulsion systems?

A: Yes, they are suitable for combustion chambers, nozzles, and fuel system components where resistance to hot gaseous hydrochloric acid is required. Actual suitability depends on specific operating parameters.

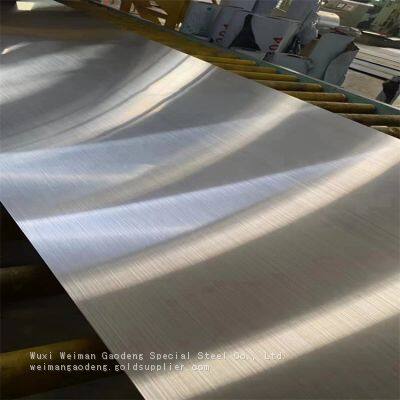

Q: What surface finishes are available?

A: Standard mill finish is supplied, with optional pickled, ground, or polished surfaces available upon request. Surface roughness can be customized to Ra ≤ 0.8μm.

Q: How does thermal cycling affect dimensional stability?

A: The alloy's low coefficient of thermal expansion (9.6 μm/m·°C at 20-100°C) minimizes dimensional changes during repeated heating/cooling cycles, critical for precision aerospace assemblies.

Q: What quality documentation is provided?

A: Each shipment includes material certification, chemical analysis reports, mechanical test results, and non-destructive testing records. Additional certifications can be discussed.

Leverage our specialized manufacturing capabilities to source premium Hastelloy N10665 plates that meet stringent aerospace requirements. With a 1,000-3,000m² production facility and annual export experience across global markets, we ensure reliable material supply with consistent quality. Contact our technical team today for project-specific quotations or material selection guidance.

All products ship from Shanghai, Ningbo, Lianyungang, or Suzhou ports with flexible Incoterms options. Minimum order quantities and lead times vary based on specifications - inquire for details.

Send Inquiry to This Supplier

You May Also Like

-

N08020 N04400 Nickel Alloy Plate Wear-Resistant Nickel Alloy SheetNegotiableMOQ: 10 Kilograms

-

N05500 N08926 Nickel Alloy Sheet High-Strength Nickel Alloy StripNegotiableMOQ: 10 Kilograms

-

N06022 N08810 Nickel Alloy Strip Heat-Resistant Nickel Alloy PlateNegotiableMOQ: 10 Kilograms

-

N07718 N07750 Nickel Alloy Plate Nickel Alloy Sheet for Industrial UseNegotiableMOQ: 10 Kilograms

-

N10665 S31254 Nickel Alloy Sheet Nickel Alloy Strip With High PurityNegotiableMOQ: 10 Kilograms

-

N08904 K93600 Nickel Alloy Strip Heavy-Duty Nickel Alloy PlateNegotiableMOQ: 10 Kilograms

-

N08031 N06600 Nickel Alloy Plate Nickel Alloy Sheet for EngineeringNegotiableMOQ: 10 Kilograms

-

N07718 N06625 Nickel Alloy Sheet High-Temp Nickel Alloy StripNegotiableMOQ: 10 Kilograms

-

N10276 N08825 Nickel Alloy Strip Corrosion-Proof Nickel Alloy PlateNegotiableMOQ: 10 Kilograms

-

N06601 N08020 Nickel Alloy Plate Nickel Alloy Sheet for MachineryNegotiableMOQ: 10 Kilograms