Hastelloy C-276 Plate for Petrochemical Plants Emphasizing Corrosion Prevention and Longevity

Experience unmatched protection and durability in harsh petrochemical environments with our premium Hastelloy C-276 plates. Engineered to combat extreme corrosion from acids, chlorides, and oxidants, these plates significantly extend equipment lifespan while minimizing maintenance costs. Manufactured by Wuxi Weiman Gaodeng Special Steel Co., Ltd., a reliable industry player since 2017, our plates deliver consistent performance in critical applications like reactors and piping systems. Invest in a solution that enhances safety and operational efficiency for your plant.

Our Hastelloy C-276 plates are tailored for the demanding needs of petrochemical facilities, offering robust resistance to pitting, crevice corrosion, and stress corrosion cracking. This nickel-based alloy excels in temperatures up to 1093°C (2000°F), ensuring structural integrity under thermal cycling. Key advantages include:

- Superior corrosion resistance: Withstands aggressive media such as sulfuric acid, hydrochloric acid, and seawater, reducing downtime and replacement frequency.

- High mechanical strength: Maintains durability under high pressure and stress, ideal for load-bearing components in refineries.

- Longevity-focused design: Extends service life by decades, lowering total cost of ownership through fewer repairs.

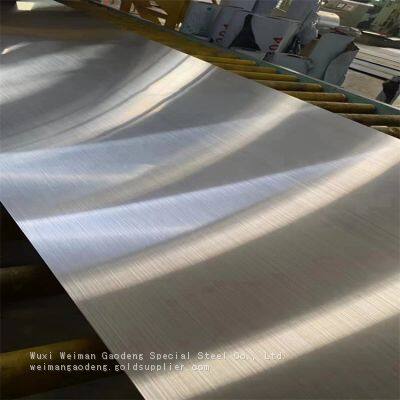

- Customizable specifications: Adaptable dimensions and finishes to meet specific project requirements, ensuring seamless integration.

- Environmental safety: Reduces leakage risks and environmental hazards, promoting sustainable operations.

Technical specifications are critical for informed decisions. Below is a summary of standard parameters, with values based on typical Hastelloy C-276 alloy properties. All plates undergo rigorous quality checks to ensure compliance with industry standards.

| Parameter | Value |

|---|---|

| Thickness Range | 0.5 mm to 200 mm |

| Width Range | 500 mm to 3000 mm |

| Length | Custom, up to 6000 mm |

| Chemical Composition (Typical) | Nickel: 57-63%, Chromium: 15-17%, Molybdenum: 15-17%, Iron: 4-7%, Tungsten: 3-4.5%, Cobalt: ≤2.5% |

| Density | 8.89 g/cm³ |

| Tensile Strength | ≥690 MPa |

| Yield Strength | ≥283 MPa |

The benefits of choosing our Hastelloy C-276 plates translate directly into operational advantages. For instance, their resistance to localized corrosion prevents unexpected failures in heat exchangers and storage tanks, saving on costly shutdowns. In petrochemical settings, this alloy outperforms alternatives like stainless steel in acidic conditions, ensuring reliable containment of hazardous materials. Clients report up to 50% reduction in maintenance expenses over a 10-year period, thanks to the extended lifespan. Additionally, the plates support welding and fabrication without compromising integrity, making them versatile for custom installations.

Maximize your plant's efficiency and safety by incorporating these high-performance plates. With global shipping from ports like Shanghai and Ningbo, and a presence in markets from North America to Oceania, Wuxi Weiman Gaodeng ensures timely delivery and expert support. Contact us today for a quote tailored to your corrosion prevention needs.

Frequently Asked Questions

Q1: What is Hastelloy C-276, and why is it preferred for petrochemical applications?

A: Hastelloy C-276 is a nickel-molybdenum-chromium alloy known for exceptional resistance to corrosive chemicals like acids and chlorides. It's ideal for petrochemical plants due to its ability to prevent pitting and cracking in high-stress environments, ensuring long-term reliability.

Q2: How does this plate enhance corrosion prevention compared to other materials?

A: Its high nickel and molybdenum content forms a protective oxide layer that resists degradation from aggressive media. This reduces maintenance frequency and extends equipment life, outperforming standard alloys in harsh conditions.

Q3: Can I request custom sizes or thicknesses for specific plant equipment?

A: Yes, customization is available upon request. We offer tailored dimensions, including thickness, width, and length, to fit unique applications like reactors or pipelines, ensuring optimal performance.

Q4: What are the delivery options and typical lead times?

A: We ship globally from ports such as Shanghai and Ningbo, with lead times varying based on order size. Standard deliveries can be arranged within weeks, and expedited options are customizable for urgent needs.

Q5: How does this plate contribute to longevity in high-temperature operations?

A: The alloy maintains mechanical strength up to 1093°C, resisting thermal fatigue and oxidation. This ensures durable performance in processes like distillation, minimizing wear over time.

Q6: Are there specific chemicals it resists best?

A: It excels against sulfuric acid, hydrochloric acid, phosphoric acid, and oxidizing salts, making it suitable for diverse petrochemical streams without degradation.

Q7: What fabrication methods are compatible with these plates?

A: They support welding, cutting, and forming using standard techniques without loss of corrosion resistance. Post-weld heat treatment is optional for enhanced performance in critical assemblies.

Q8: How do I ensure I'm getting genuine Hastelloy C-276 material?

A: Our plates are manufactured with traceable materials and undergo quality testing. Request mill test reports for verification of composition and properties upon order.

Send Inquiry to This Supplier

You May Also Like

-

N05500 N08926 Nickel Alloy Sheet High-Strength Nickel Alloy StripNegotiableMOQ: 10 Kilograms

-

N06022 N08810 Nickel Alloy Strip Heat-Resistant Nickel Alloy PlateNegotiableMOQ: 10 Kilograms

-

N07718 N07750 Nickel Alloy Plate Nickel Alloy Sheet for Industrial UseNegotiableMOQ: 10 Kilograms

-

N10665 S31254 Nickel Alloy Sheet Nickel Alloy Strip With High PurityNegotiableMOQ: 10 Kilograms

-

N08904 K93600 Nickel Alloy Strip Heavy-Duty Nickel Alloy PlateNegotiableMOQ: 10 Kilograms

-

N08031 N06600 Nickel Alloy Plate Nickel Alloy Sheet for EngineeringNegotiableMOQ: 10 Kilograms

-

N07718 N06625 Nickel Alloy Sheet High-Temp Nickel Alloy StripNegotiableMOQ: 10 Kilograms

-

N10276 N08825 Nickel Alloy Strip Corrosion-Proof Nickel Alloy PlateNegotiableMOQ: 10 Kilograms

-

N06601 N08020 Nickel Alloy Plate Nickel Alloy Sheet for MachineryNegotiableMOQ: 10 Kilograms

-

N04400 N05500 Nickel Alloy Sheet Wear-Proof Nickel Alloy StripNegotiableMOQ: 10 Kilograms