Cut to Length Alloy 36 Steel Plate UNS K93603 Invar 36 Corrosion Resisting

Invar 36 Steel Plate - Product Details

Invar 36 steel plate is a nickel-iron alloy (containing 36% nickel), renowned for its extremely low coefficient of thermal expansion (CTE) and dimensional stability. It is widely used in precision fields with high temperature sensitivity requirements. Below are its core product details:

I. Material Properties1. Chemical Composition

◦ Nickel (Ni): 35.0-37.0%

◦ Iron (Fe): Balance

◦ Other elements: Carbon (≤0.05%), Manganese (≤0.60%), Silicon (≤0.30%), Phosphorus (≤0.02%), Sulfur (≤0.02%).Impurity content varies slightly across standards (e.g., ASTM F1684, EN 1.3912), but the core composition remains consistent.

2. Physical Properties

◦ Density: 8.1 g/cm³

◦ Melting Point: 1430-1450℃

◦ Coefficient of Thermal Expansion (CTE):

▪ 20-50℃: 0.6×10⁻⁶/℃

▪ 20-200℃: 2.0×10⁻⁶/℃

▪ 20-500℃: 10.0×10⁻⁶/℃ (gradually increasing with temperature)

◦ Curie Point: Approximately 230℃. Below this temperature, the alloy is ferromagnetic, with the lowest expansion coefficient.

3. Mechanical Properties

◦ Tensile Strength: 400-690 MPa

◦ Yield Strength: 216-345 MPa

◦ Elongation: ≥20%

◦ Elastic Modulus: 140-148 GPaPerformance is more stable in the annealed state. Annealing at 850-900℃ is recommended to eliminate stress.

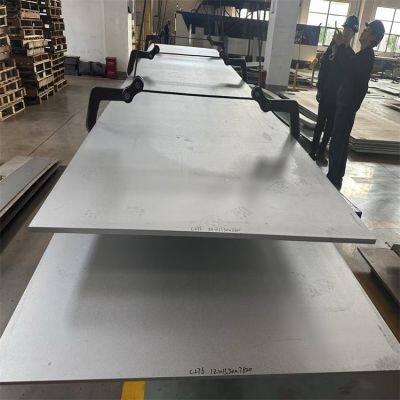

II. Product Specifications• Thickness: 0.3-1200 mm

• Width: Max. 2500 mm

• Length: Max. 12 m; customizable coils or plates available

• Surface Treatment: Offers 1D, 2B, BA, 3/4/6/7-grade surfaces (polished, sandblasted, etc.).

III. Production Standards• International Standards: ASTM F1684 (free-machining type), EN 1.3912 (Germany), UNS K93600 (USA).

• Chinese Standard: 4J36 (equivalent to Invar 36).

• Flaw Detection Standards: GB/T 5616-2006, GB/T 15024.

IV. Processing & Welding• Forming Process: Suitable for hot/cold rolling, with forming processes similar to austenitic stainless steel.

• Welding Recommendations: Use CF36 filler metal (GTAW/GMAW processes). Interpass temperature should be below 120℃ to avoid thermal stress.

• Heat Treatment: Full annealing (850-900℃) optimizes dimensional stability; customized stabilization processes are available for special applications.

V. Typical Applications4. Aerospace: Satellite structural components, cryogenic fuel storage tanks, precision instrument brackets.

5. Electronics Industry: Wafer carriers for semiconductor equipment, integrated circuit packaging frames.

6. Optical Instruments: Telescope tubes, laser component brackets (reducing temperature-induced optical path deviation).

7. Cryogenic Engineering: LNG transport pipelines, liquid helium containers (maintaining low expansion at -200℃).

8. Precision Machinery: Clock balance wheels, measuring tools, thermostat components.

VI. Notes• Corrosion Resistance: Performs well in dry environments but may rust in humid conditions. Surface coating or passivation is recommended.

• Temperature Limit: Long-term service temperature is advised below 200℃; CTE increases significantly above the Curie point (230℃).

• Processing Deformation: Cold deformation can further reduce CTE, but annealing is required to restore ductility.

VII. Supply & Certification• Common Forms: Plates, strips, coils, forgings; custom cutting available.

• Certification Support: Provide material certificates compliant with ASTM, EN, etc.; third-party flaw detection reports available from some suppliers.

For specific models or supplier information, please contact material manufacturers (e.g., Muyan Alloy, Shanghai Kangdeli) directly for the latest quotations and inventory status.

Send Inquiry to This Supplier

You May Also Like

-

N06022 N08810 Nickel Alloy Strip Heat-Resistant Nickel Alloy PlateNegotiableMOQ: 10 Kilograms

-

N07718 N07750 Nickel Alloy Plate Nickel Alloy Sheet for Industrial UseNegotiableMOQ: 10 Kilograms

-

N10665 S31254 Nickel Alloy Sheet Nickel Alloy Strip With High PurityNegotiableMOQ: 10 Kilograms

-

N08904 K93600 Nickel Alloy Strip Heavy-Duty Nickel Alloy PlateNegotiableMOQ: 10 Kilograms

-

N08031 N06600 Nickel Alloy Plate Nickel Alloy Sheet for EngineeringNegotiableMOQ: 10 Kilograms

-

N07718 N06625 Nickel Alloy Sheet High-Temp Nickel Alloy StripNegotiableMOQ: 10 Kilograms

-

N10276 N08825 Nickel Alloy Strip Corrosion-Proof Nickel Alloy PlateNegotiableMOQ: 10 Kilograms

-

N06601 N08020 Nickel Alloy Plate Nickel Alloy Sheet for MachineryNegotiableMOQ: 10 Kilograms

-

N04400 N05500 Nickel Alloy Sheet Wear-Proof Nickel Alloy StripNegotiableMOQ: 10 Kilograms

-

N08926 N06022 Nickel Alloy Strip High-Strength Nickel Alloy PlateNegotiableMOQ: 10 Kilograms