Industrial Oil-Free Water Lubricated Air Compressor 0.8-1.2MPa for Critical Applications

WSV Series Oil-Free Water Lubricated Permanent Magnet Variable Frequency Screw Air Compressor

Product Overview

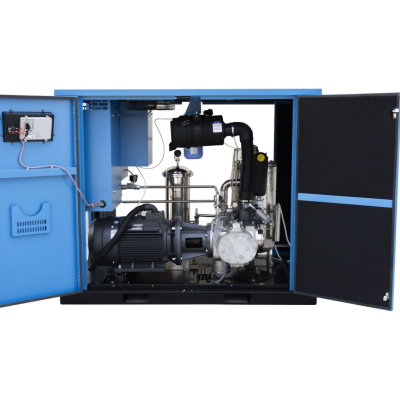

The WSV Series represents the pinnacle of oil-free compression technology, combining water lubrication with permanent magnet variable frequency drive for exceptional efficiency and reliability. This 100% oil-free compressor eliminates any risk of oil contamination, making it ideal for critical applications in medical, pharmaceutical, food processing, and electronics industries. With isothermal compression technology maintaining operating temperatures below 50°C, it achieves 15% higher energy efficiency compared to traditional oil-free screw compressors.

Key Features & Advantages:

100% Oil-Free Operation: Complete elimination of oil contamination risk, ensuring pure compressed air output

Energy Efficient: Permanent magnet motor with variable frequency drive saves over 15% energy compared to conventional oil-free screw compressors

Easy Maintenance: Minimal maintenance requirements with only air filters and water filters as consumables

Intelligent Operation: Smart control system with automatic protection, enabling 24-hour unmanned operation and remote monitoring

Automatic Water Management: Regular automatic water change and cleaning functions maintain internal hygiene

Low Noise Operation: Precision machining ensures smooth operation with noise levels as low as 58dB

Integrated Design: Compact unit with simplified piping and wiring, reducing potential failure points

Applications:

Medical and healthcare facilities

Pharmaceutical manufacturing

Food and beverage processing

Electronics and semiconductor

Chemical and laboratory applications

Technical Parameters WSV Series Oil-Free Water Lubricated Permanent Magnet Variable Frequency Screw Air Compressor

| MODEL | Capacity (m²/min) | Water Inlet 32℃ (T/H) | Water (L) | Power (KW) | Noise (dB(A)) | Outlet (INCH) | Dimension (WxDxH mm) | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|

| WSV-10A | 1.2-0.8 | 2.0 | 10 | 7.5 | 58±2 | G3/4" | 800x800x1100 | 510 |

| WSV-15A | 1.6-1.1 | 2.5 | 26 | 11 | 60±2 | G3/4" | 1200x760x1300 | 620 |

| WSV-20A | 2.4-1.8 | 3.5 | 26 | 15 | 63±2 | G3/4" | 1200x760x1300 | 670 |

| WSV-25A | 3.1-2.1 | 4.0 | 30 | 18.5 | 65±2 | G1" | 1400x900x1450 | 720 |

| WSV-30A | 3.5-2.8 | 5.0 | 30 | 22 | 65±2 | G1" | 1400x900x1450 | 760 |

| WSV-40A | 5.1-3.6 | 7.0 | 40 | 30 | 68±2 | G11/4" | 1550x1150x1500 | 1050 |

| WSV-50A/W | 6.3-4.8 | 9.0 | 40 | 37 | 68±2 | G11/4" | 1550x1150x1500 | 1200 |

| WSV-60A/W | 7.4-5.6 | 10.0 | 90 | 45 | 70±2 | G2" | 1800x1300x1750 | 1450 |

| WSV-75A/W | 9.7-7.7 | 12.0 | 100 | 55 | 70±2 | G2" | 1800x1300x1750 | 1550 |

| WSV-100A/W | 13.0-9.7 | 18.0 | 100 | 75 | 73±2 | G2" | 1800x1300x1750 | 1650 |

| WSV-120A/W | 14.8-12.6 | 20.0 | 120 | 90 | 73±2 | G21/2" | 2200x1550x1800 | 2400 |

| WSV-150A/W | 19.8-15.6 | 24.0 | 120 | 110 | 78±2 | G21/2" | 2200x1550x1800 | 2550 |

| WSV-175A/W | 23.1-16.8 | 31.0 | 120 | 132 | 78±2 | G21/2" | 2200x1550x1800 | 2750 |

| WSV-200A/W | 28.1-22.5 | 36.0 | 160 | 160 | 80±2 | G3" | 3000x1800x2100 | 3800 |

| WSV-250A/W | 33.9-25.2 | 38.0 | 160 | 185 | 80±2 | G3" | 3000x1800x2100 | 4000 |

| WSV-280A/W | 36.8-29.1 | 42.0 | 200 | 200 | 80±2 | G4" | 3100x1850x2000 | 4200 |

| WSV-350A/W | 39.7-29.5 | 46.0 | 200 | 220 | 82±2 | G4" | 3100x1850x2000 | 4400 |

| WSV-420A/W | 43.5-34.1 | 52.0 | 200 | 250 | 82±2 | G4" | 3100x1850x2000 | 4600 |

Frequently Asked Questions (FAQs)

What is an oil-free air compressor?

An oil-free air compressor is a type of compressor that operates without the use of lubricating oil in the compression chamber. This design prevents oil from contaminating the compressed air, which is essential in industries requiring high air purity.

How do oil-free air compressors differ from oil-lubricated compressors?

Oil-free compressors rely on specific materials and precise engineering for lubrication and cooling, instead of oil. This results in reduced maintenance requirements and eliminates the risk of oil contamination in critical compressed air applications.

What industries typically require oil-free air compressors?

Industries such as pharmaceuticals, food and beverage, electronics, healthcare, and biotechnology demand oil-free compressed air to comply with stringent safety and purity standards.

How can I ensure the reliability of an oil-free air compressor?

Perform scheduled preventive maintenance, including filter inspections, system diagnostics, and adherence to manufacturer guidelines, to maintain consistent operation and prolong equipment lifespan.

Do oil-free air compressors require special operating conditions?

These compressors generally require clean, dry intake air and a stable operating environment. Regular monitoring of air filters and moisture control is important to maintain optimal performance.

Send Inquiry to This Supplier

You May Also Like

-

Industrial Single-Stage Permanent Magnet Variable Frequency Screw CompressorNegotiableMOQ: 1 Unit

-

High Efficiency SCV Series Single-Stage Permanent Magnet VFD Screw Air Compressor With Adaptive Pressure ControlNegotiableMOQ: 1 Unit

-

High-Efficiency Low-Pressure Screw Type Air Compressor for Pneumatic Conveying & Blow MoldingNegotiableMOQ: 1 Unit

-

Industrial Low-Pressure Screw Air Compressor for Textile Manufacturing & Cement ProductionNegotiableMOQ: 1 Unit

-

Low-Pressure Screw Air Compressor With 10-30 PSI Range and Compact Size for Efficient Industrial OperationsNegotiableMOQ: 1 Unit

-

Energy-Efficient Low-Pressure Screw Air Compressor Ideal for Painting and Sandblasting Applications in WorkshopsNegotiableMOQ: 1 Unit

-

Energy-Saving Low Pressure Screw Compressor for Blow Molding & Gas Transmission ApplicationsNegotiableMOQ: 1 Unit

-

Industrial Rotary Screw Air Compressor Compatible With Pneumatic Tools in ManufacturingNegotiableMOQ: 1 Unit

-

Energy-Efficient Rotary Screw Air Compressor With Variable Speed Drive for Cost SavingsNegotiableMOQ: 1 Unit

-

Rotary Screw Air Compressor Designed for Construction Sites Featuring Low Noise OperationNegotiableMOQ: 1 Unit