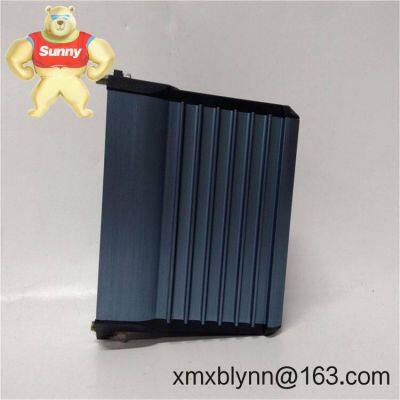

Foxboro IPM2-P0904HA Series Industrial Power Module – Stable, Cabinet-grade Power for I/A Series Baseplates

Warranty: 365 days

Delivery: 1 week if in stock; no more than one month at the latest

Payment: 50% advance payment; full payment prior to delivery

Express options: FedEx, UPS, DHL

Designed for Foxboro I/A Series 200 Series baseplates: A direct fit for IPM2 power positions, which keeps cabinet layouts unchanged.

Regulated DC output to the baseplate bus: Provides conditioned power to FBMs for stable operation, particularly under fluctuating mains or load conditions.

Redundancy support: Typically used in A/B redundant pairs; you can replace one side while the other carries the load in many cases.

Front status indication: LED status aids quick cabinet checks without opening tools or software.

Industrial temperature tolerance: Suitable for common cabinet environments found in refining, chemicals, power, and water plants.

Low-noise power architecture: Helps minimize electrical noise introduced to sensitive I/O modules on the backplane.

| Brand / Model | Foxboro IPM2-P0904HA Series |

| HS Code | 8504.40 (Static converters / power supply modules) |

| Power Requirements | 24 VDC nominal input (commonly 18–32 VDC window), regulated output to baseplate bus |

| Operating Temperature | 0 to +55 °C typical cabinet ambient |

| Signal I/O Types | N/A (power module; no process I/O) |

| Communication Interfaces | None; front-panel status LEDs only |

| Installation Method | Plug-in to Foxboro 200 Series FBM baseplate power slot; supports redundant A/B configuration |

| Form Factor / Weight | Compact plug-in module; typically under 0.5 kg |

Plants using Foxboro I/A Series control systems—especially with 200 Series FBMs—will find the IPM2-P0904HA a practical fit. It’s commonly deployed in:

Oil & Gas and petrochemical units requiring redundant power at the I/O baseplate level

Power generation balance-of-plant cabinets with mixed analog/digital FBMs

Water and wastewater facilities where panel space is tight and downtime windows are short

Specialty chemicals and batch plants with phased modernization of I/A Series nodes

Drop-in compatibility: Keeps wiring and baseplate layout intact—less risk during turnarounds.

Redundancy done right: A/B pairing reduces single points of failure and typically allows live replacement of one side.

Lifecycle support: A sensible way to extend the life of existing Foxboro I/A Series nodes without a full cabinet redesign.

Lower maintenance burden: No firmware to manage; quick visual status checks via LEDs.

Procurement simplicity: Clear HS classification and short lead options help with project scheduling and customs.

One thing I appreciate is how predictable these modules behave under load; brownouts are rare when cabinet DC is sized correctly. A maintenance lead from a midstream gas site told us, “Swapped the A-side during a day shift—no alarms, the B-side carried it seamlessly.”

Installation & MaintenanceCabinet environment: Install in a clean, ventilated enclosure meeting typical industrial control cabinet standards; avoid hot spots near VFDs.

Wiring: Use appropriately rated 24 VDC feeds with proper fusing or breakers; keep returns and protective earth consistent with site standards.

Redundant pairing: When used as A/B, verify load sharing and alarm logic before commissioning; label sides clearly.

ESD and handling: De-energize if you’re not performing a controlled redundant swap; follow ESD precautions when inserting/removing the module.

Ventilation: Provide clearance around the module face for heat dissipation and access to LEDs.

Routine checks: Quarterly visual inspection for connector oxidation and terminal tightness; verify cabinet DC health and ripple.

No firmware: Nothing to update—just keep connections clean and the cabinet DC within the specified window.

Certifications: Typically CE and UL/cUL for industrial control equipment; RoHS compliance where applicable.

Manufacturing quality: Built for continuous-duty industrial environments associated with Foxboro I/A Series systems.

Warranty: 365-day coverage from us; manufacturer’s labeling and conformity marks present on the module.

You might notice that this module seems simple on paper—and that’s the point. In many cases, the safest upgrade is the one that fits your baseplate, preserves redundancy, and just works shift after shift.

Send Inquiry to This Supplier

You May Also Like

-

Foxboro P0916CC I/A Series Module – Form-Fit Replacement for I/A Series Control SystemsUS$ 2560.00MOQ: 1 Blade

-

FOXBORO P0916PH / P0916JS Terminal Block Module – Reliable Field Wiring Interface for I/A Series FBMsUS$ 2560.00MOQ: 1 Blade

-

FOXBORO P0916XT Contact Sense Input Module – Reliable Dry-contact Monitoring for Foxboro DCSUS$ 2560.00MOQ: 1 Blade

-

Foxboro P0917MF Control Processor – Reliable CPU Module for I/A Series (200 Series) Distributed ControlUS$ 2560.00MOQ: 1 Blade

-

Foxboro P0917XV Compression Termination Assembly – Clean, Reliable Field Wiring for I/A Series FBM I/OUS$ 2560.00MOQ: 1 Blade

-

Foxboro P0924JH Compact Power Supply – Stable Backplane Power for Foxboro Compact/200 Series I/OUS$ 2560.00MOQ: 1 Blade

-

Foxboro P0926GH Communication Terminal – Reliable Field Termination for Foxboro DCS Serial CommunicationsUS$ 2560.00MOQ: 1 Blade

-

Foxboro P0973CN Expansion Backplane – Expand I/A Series/200 Series I/O Capacity With Clean, Redundant DistributionUS$ 2560.00MOQ: 1 Blade

-

Foxboro P0973LQ Network Power Supply – Stable DC Power for I/A Series Nodes and Control CabinetsUS$ 2560.00MOQ: 1 Blade

-

FOXBORO RH916XG Input Module – Multi‑Channel Analog Input for I/A Series DCSUS$ 2560.00MOQ: 1 Blade