High-Toughness TC10 Titanium Alloy Bar / Shock-Resistant Titanium Rod for Aerospace Landing Gear Parts

Product Overview

Our High - Toughness TC10 Titanium Alloy Bar, also known as the Shock - Resistant Titanium Rod, is a premium product specifically designed for aerospace landing gear parts. With the increasing demand for high - performance materials in the aerospace industry, this titanium alloy bar stands out as a reliable and durable solution.

Material and Surface Treatment

- Material: The bar is crafted from TC10 titanium alloy. Titanium is well - known for its excellent strength - to - weight ratio, corrosion resistance, and high - temperature performance. The TC10 alloy, in particular, offers enhanced toughness and shock - resistance, making it ideal for the high - stress environment of aerospace landing gear.

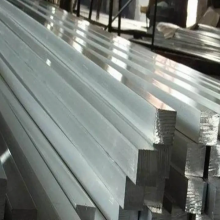

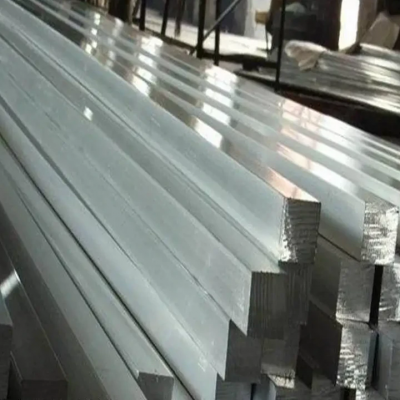

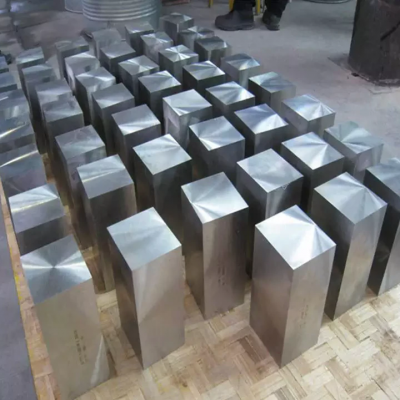

- Surface Treatment: It has a bright rod surface treatment. This not only gives the bar an aesthetically pleasing silver color but also provides a smooth finish. The bright surface reduces friction and can potentially enhance the bar's corrosion resistance, protecting it from the harsh aerospace environment.

Shape and Dimensions

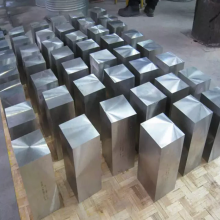

- Shape: The product comes in a bar shape, which is a common and practical form for manufacturing landing gear parts. Bars are easy to machine and can be fabricated into various components such as struts, brackets, and pins.

- Customization: While standard dimensions are available, we also offer custom - cutting services. We can cut pipes with an outer diameter ranging from 20mm to 1200mm and plates with a maximum thickness of 120mm. This flexibility allows us to meet the specific requirements of different aerospace projects.

Performance and Features

- High Toughness: The TC10 titanium alloy bar has exceptional toughness, which means it can withstand high - impact forces without fracturing. In the context of aerospace landing gear, this is crucial as landing gear parts experience significant shock loads during take - off and landing.

- Shock Resistance: It is specifically engineered to be shock - resistant. This property ensures that the landing gear can absorb and dissipate the energy generated during landing, protecting the aircraft and its passengers.

- Corrosion Resistance: Titanium alloys are inherently corrosion - resistant, and the TC10 alloy is no exception. This is vital for aerospace applications, as landing gear parts are often exposed to harsh weather conditions, including saltwater and moisture. The corrosion resistance of the bar extends its service life and reduces maintenance costs.

- High - Temperature Performance: The bar can maintain its mechanical properties at high temperatures. This is important because landing gear parts may experience heat generated during high - speed flight and braking. The ability to perform well under high - temperature conditions ensures the safety and reliability of the landing gear.

Manufacturing and Quality Assurance

- Advanced Manufacturing Process: Our company uses state - of - the - art manufacturing techniques. For example, we have automated production lines that cover stainless steel, nickel alloys, titanium, and forgings up to 20m in length. The 4000 - ton hydraulic presses are used to produce heavy - duty forgings, ensuring the structural integrity of the bar.

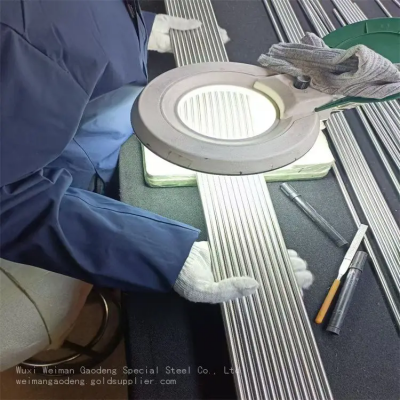

- Quality Testing: We have a comprehensive quality testing system in place. Our advanced NDT (Non - Destructive Testing) services include Ultrasonic Testing (UT) to EN 10228 - 3, which can detect internal defects as small as 0.5mm. Magnetic Particle Testing (MT) is used to detect surface cracks, and our testing facilities are certified by SGS and BV. This ensures that every bar meets the strict quality standards required for aerospace applications.

Company Background and Support

- Established Manufacturer: Our company, Wuxi Weiman Gaodeng Special Steel Co., Ltd., was established in 2017. We are a manufacturer with a strong focus on high - precision special steel solutions.

- Global Reach: We have a significant export share ranging from US$5 Million - US$10 Million. Our products are sold in major markets around the world, including North America, South America, Europe, Asia, Africa, and Oceania.

- Expert Team: Our leadership team consists of experienced professionals. Mr. Sang Le, the CEO, has over 20 years of experience in the special steel industry and is well - versed in EU/US market compliance. Dr. Li Wei, the Chief Metallurgist, holds a PhD in Materials Science from Tsinghua University and specializes in creep - resistant alloys and titanium metallurgy.

- Customized Solutions and Services: We provide customized materials and value - added services for global industries. We ensure that our products comply with international standards such as ASTM, EN, JIS, and API. Whether it's for a small - scale project or a large - scale aerospace program, we can offer tailored solutions to meet your specific needs.

- Rapid Logistics: With strategically located warehouses in Wuxi, we can ensure 48 - hour delivery to major Chinese ports. This fast and reliable logistics service helps our customers reduce lead times and keep their projects on schedule.

Send Inquiry to This Supplier

You May Also Like

-

Precision Machined TC4ELI Titanium Bar GR5 ELI High-Precision Titanium Rod for Medical ImplantsNegotiableMOQ: 100 Kilograms

-

Forged TA9 Titanium Bar GR7 Wear-Resistant Forged Titanium Rod for Chemical Industry EquipmentNegotiableMOQ: 100 Kilograms

-

Rolled TC6 Titanium Alloy Bar Smooth-Surface Rolled Titanium Rod for Industrial Machinery ComponentsNegotiableMOQ: 100 Kilograms

-

Precision Ground TA1 Titanium Bar GR1 Ultra-Precision Titanium Rod for Medical Device PartsNegotiableMOQ: 100 Kilograms

-

Forged TC11 Titanium Alloy Bar Heavy-Duty Forged Titanium Rod for Aerospace Engine ComponentsNegotiableMOQ: 100 Kilograms

-

Rolled TA10 Titanium Bar GR12 Corrosion-Resistant Rolled Titanium Rod for Marine Industrial SystemsNegotiableMOQ: 100 Kilograms

-

Precision Cut TC10 Titanium Alloy Bar High-Accuracy Titanium Rod for Industrial Control PartsNegotiableMOQ: 100 Kilograms

-

Forged TA3 Titanium Bar GR3 High-Strength Forged Titanium Rod for Industrial Pressure VesselsNegotiableMOQ: 100 Kilograms

-

Surgical Titanium Products Medical Titanium Alloy Round Rod for Orthopedic ImplantsNegotiableMOQ: 100 Kilograms

-

Titanium Rod GR1、GR2、GR3、GR5、GR7 Titanium Alloy Bar for MedicalNegotiableMOQ: 100 Kilograms