Home > Products > Titanium Alloy > Wear-Resistant TC6 Titanium Alloy Bar / High-Performance Titanium Rod for Aerospace Mechanical Parts

Wear-Resistant TC6 Titanium Alloy Bar / High-Performance Titanium Rod for Aerospace Mechanical Parts

- Shanghai

- T/T L/C

- 1 days

You May Like

-

High-Precision Machined TA7 Titanium Bar / Smooth-Surface Titanium Rod for Aerospace Instrument Components

-

Forged TC4 Titanium Alloy Bar GR5 High-Density Forged Titanium Rod for Aerospace Structural Parts

-

Rolled TA2 Pure Titanium Bar GR2 Uniform-Thickness Rolled Titanium Rod for Industrial Pipes

-

Precision Machined TC4ELI Titanium Bar GR5 ELI High-Precision Titanium Rod for Medical Implants

-

Forged TA9 Titanium Bar GR7 Wear-Resistant Forged Titanium Rod for Chemical Industry Equipment

-

Rolled TC6 Titanium Alloy Bar Smooth-Surface Rolled Titanium Rod for Industrial Machinery Components

Product Details

| Surface Treatment | Other, Bright rod | Shape | Bar | |

| Color | Silver | Material | Other, Titanium |

Product Description

Product Overview

Introducing our Wear - Resistant TC6 Titanium Alloy Bar, a high - performance titanium rod specifically designed for aerospace mechanical parts. Crafted with precision and expertise, this product stands out in the market due to its exceptional properties and suitability for the demanding aerospace industry.

Material and Composition

The bar is made from TC6 titanium alloy, a remarkable material that combines the strength of titanium with excellent wear - resistant characteristics. Titanium is well - known for its high strength - to - weight ratio, which is crucial in aerospace applications where every gram matters. The TC6 alloy composition is carefully engineered to enhance its mechanical properties, providing superior performance under extreme conditions. The alloy contains a balanced mix of elements that contribute to its overall durability and resistance to corrosion, ensuring a long service life even in harsh aerospace environments.

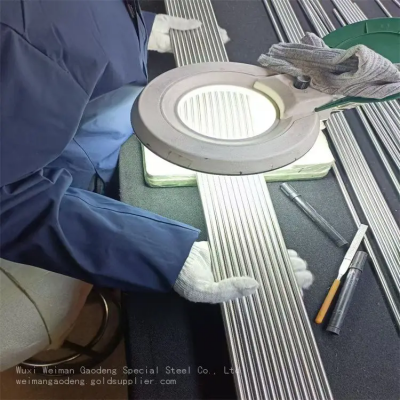

Surface Treatment and Appearance

The surface treatment of this titanium bar is a bright rod finish. This not only gives it an aesthetically pleasing silver color but also provides additional benefits. The bright finish helps in reducing friction, which is essential for mechanical parts in aerospace applications. It also makes the bar more resistant to surface damage and wear, as the smooth surface is less likely to catch debris or experience abrasion. The uniform silver color is a sign of the high - quality manufacturing process, indicating that the bar has been produced with strict quality control measures.

Shape and Dimensions

The product comes in a bar shape, which is a common and versatile form for aerospace mechanical parts. Bars can be easily machined into various components such as shafts, bolts, and connectors. Our manufacturing capabilities allow us to offer a wide range of dimensions to meet different customer requirements. Whether you need a small - diameter rod for a precision component or a larger bar for a more substantial part, we can customize the dimensions to fit your specific needs. The precise shape and dimensions ensure a perfect fit in your aerospace assemblies, reducing the need for additional modifications and saving you time and cost.

Performance in Aerospace Applications

In the aerospace industry, performance is of utmost importance. Our TC6 titanium alloy bar excels in this regard. Its high strength allows it to withstand the extreme forces and stresses experienced during flight, such as high - speed vibrations and sudden changes in pressure. The wear - resistant property ensures that the parts made from this bar will not deteriorate quickly, even when in constant contact with other components. This is crucial for maintaining the safety and reliability of aerospace systems. Moreover, the corrosion resistance of the titanium alloy protects the parts from the effects of moisture, chemicals, and other environmental factors commonly encountered in aerospace operations.

Manufacturing and Quality Assurance

Our company, a leading manufacturer in the special steel industry since 2017, has a wealth of experience and advanced technology in producing high - quality titanium alloy bars. We have a team of experts, including a CEO with over 20 years of experience in the special steel field and a chief metallurgist with a PhD from Tsinghua University. Our technical staff consists of 12 ASME - certified NDT Level III inspectors and 5 NADCAP - qualified engineers, ensuring that every bar meets the highest quality standards. We use state - of the - art manufacturing processes, including 4000 - ton hydraulic presses for forging and advanced NDT services such as Ultrasonic Testing (UT) to EN 10228 - 3 and Magnetic Particle Testing (MT) for surface cracks. These testing methods can detect even the smallest internal and surface defects, guaranteeing the integrity of the product.

Global Reach and Customization Services

We have a significant export share of US$5 Million - US$10 Million and serve a wide range of markets, including North America, South America, Europe, Asia, Africa, and Oceania. This global presence is a testament to the quality and reliability of our products. We also offer specialized high - precision special steel solutions. We can provide customized materials and value - added services for global industries, ensuring compliance with international standards such as ASTM, EN, JIS, and API. Whether you need a standard product or a highly customized solution for your aerospace mechanical parts, our team is ready to work with you to meet your specific requirements.

Sustainability and Environmental Considerations

In addition to our focus on quality and performance, we are also committed to sustainability. Our manufacturing operations run automated lines covering stainless steel, nickel alloys, and titanium, and we recycle 95% of our waste. This not only reduces our environmental impact but also demonstrates our responsibility as a global manufacturer. By choosing our Wear - Resistant TC6 Titanium Alloy Bar, you are not only getting a high - quality product but also supporting a sustainable and environmentally friendly manufacturing process.

In conclusion, our Wear - Resistant TC6 Titanium Alloy Bar is the ideal choice for aerospace mechanical parts. With its excellent material properties, high - quality manufacturing, global reach, and commitment to sustainability, it offers a comprehensive solution for your aerospace needs.

Company Profile

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1. Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2. Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3. Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4. Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameSang Le Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu

Product Categories

New Products

-

Precision Ground TA1 Titanium Bar GR1 Ultra-Precision Titanium Rod for Medical Device Parts

-

Forged TC11 Titanium Alloy Bar Heavy-Duty Forged Titanium Rod for Aerospace Engine Components

-

Rolled TA10 Titanium Bar GR12 Corrosion-Resistant Rolled Titanium Rod for Marine Industrial Systems

-

Precision Cut TC10 Titanium Alloy Bar High-Accuracy Titanium Rod for Industrial Control Parts

-

Forged TA3 Titanium Bar GR3 High-Strength Forged Titanium Rod for Industrial Pressure Vessels

-

Surgical Titanium Products Medical Titanium Alloy Round Rod for Orthopedic Implants

-

Titanium Rod GR1、GR2、GR3、GR5、GR7 Titanium Alloy Bar for Medical

-

Pure Titanium Titanium Alloys Rod High Strength GR1、GR2、GR3、GR5、GR7

-

Titanium Alloy Rod TC4/TA2 for Aerospace And Industrial Applications, Factory Direct Supply

-

OEM GR5/GR7 Titanium Alloy Bar for Medical Implants And Industrial Use, Custom Size

-

Pure Titanium Rod TA1/TA3 High Purity for Chemical And Marine Environments, Factory Price

-

GR2/GR12 Titanium Alloy Rod Rolled And Precision Ground by Factory Experts for Engineering Use

-

Heat Resistant TC6/TC4 Titanium Alloy Bar, Factory Manufactured for High-Temperature Applications

-

Titanium Alloy Rod TA10/GR5 High Strength for Aerospace Parts, Factory Direct Supply

-

Pure Titanium Rod GR1/GR3 Corrosion Resistant, Manufactured by Top Titanium Factory

-

Medical Grade TC9/TA7 Titanium Alloy Rod for Surgical Implants And Prosthetics, Factory Supply

-

GR12/GR7 Titanium Alloy Bar for Industrial Equipment, OEM Factory Supply for High-Pressure Use

-

Titanium Rod TA2/TA3 Factory Direct for Chemical And Food Processing, Non-Toxic Material

-

Titanium Alloy Rod GR5/GR7 Custom Size for Aerospace And Medical Applications, Factory Supply

-

High Strength TA2/TA3 Titanium Rod for Marine And Chemical Industries, Direct Factory Supply

-

Titanium Alloy Bar GR1/GR3 Corrosion Resistant, Factory Manufactured for Industrial Use

-

TC4/TA10 Titanium Alloy Rod for High-Temperature Applications, Factory Direct Supply

-

Pure Titanium Bar GR2/TA7 for Medical And Aerospace Use, OEM Factory Manufactured

-

TC6/GR12 Titanium Alloy Rod for Engineering And Manufacturing, High-Performance Material

Popular Searches

- stainless steel

- bicycle frame

- titanium material

- titanium plate

- titanium bar

- titanium sheet

- titanium wire

- welding rod

- round rod

- pure titanium

- ti

- golf set

- titanium alloy sheet

- titanium alloy plate

- tungsten carbide rod

- titanium coil

- alloy bar rod

- carbide rod

- titanium nut

- molybdenum alloy rod

- titanium bar rod

- ti rod

- square bar rod

- alloy parts rod

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Alloy > Titanium Alloy

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile