Precision Cut TC10 Titanium Alloy Bar High-Accuracy Titanium Rod for Industrial Control Parts

Precision Cut TC10 Titanium Alloy Bar: High - Accuracy Titanium Rod for Industrial Control Parts

1. Product Overview

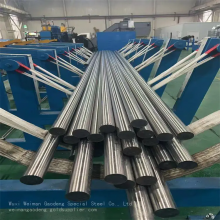

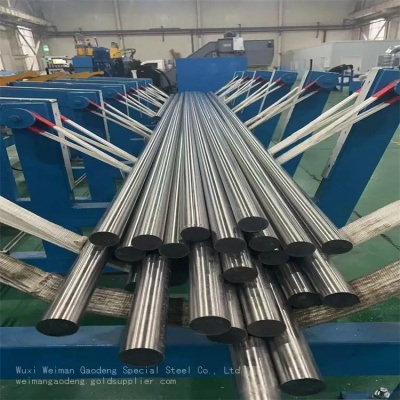

Our Precision Cut TC10 Titanium Alloy Bar is a high - performance product designed specifically for industrial control parts. With its exceptional material properties and precise manufacturing, it stands out as a reliable choice for a wide range of industrial applications. Made from high - quality TC10 titanium alloy, this bar offers a perfect balance of strength, corrosion resistance, and lightweight characteristics.

2. Material and Surface Treatment

- Material: The bar is crafted from TC10 titanium alloy. Titanium is well - known for its outstanding strength - to - weight ratio. TC10, in particular, has excellent mechanical properties, including high tensile strength and good ductility. It can withstand high stress and extreme working conditions, making it ideal for industrial control parts that often operate under challenging environments.

- Surface Treatment: The surface of the bar is treated as a bright rod. This bright finish not only gives the bar an aesthetically pleasing appearance but also provides some degree of protection against surface corrosion. The smooth surface finish also reduces friction, which can be beneficial in applications where the bar needs to move or interact with other components.

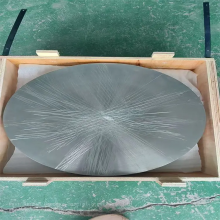

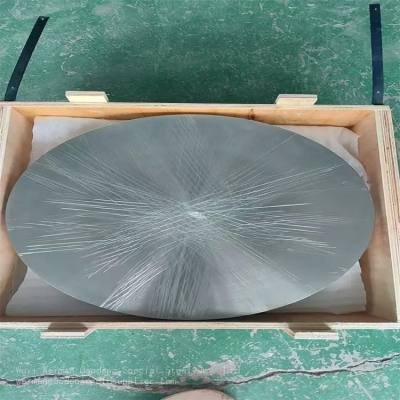

3. Shape and Dimensions

- Shape: The product comes in the shape of a bar. The bar shape is a common and versatile form, making it easy to machine and integrate into various industrial control systems. It can be cut, drilled, and milled according to specific design requirements.

- Precision Cutting: Our manufacturing process ensures high - precision cutting of the TC10 titanium alloy bar. The cutting accuracy is extremely high, which is crucial for industrial control parts. Precise dimensions guarantee a perfect fit within the overall system, reducing the risk of malfunctions and improving the overall performance of the industrial control equipment.

4. Color and Aesthetic Appeal

The bar has a silver color, which is characteristic of titanium alloys. The silver hue gives the bar a modern and professional look. In addition to its aesthetic value, the silver color can also be an advantage in some applications where visibility or identification of the component is important.

5. Applications in Industrial Control

- High - Precision Control: In industrial control systems, high - precision components are essential. The TC10 titanium alloy bar can be used to manufacture parts such as actuators, valves, and sensors. Its high strength and precision dimensions ensure accurate control and reliable operation of these components.

- Corrosion - Prone Environments: Many industrial control parts are exposed to harsh chemicals or corrosive substances. The corrosion resistance of TC10 titanium alloy makes the bar suitable for use in such environments. It can maintain its integrity and performance over a long period, reducing the need for frequent replacements and maintenance.

- Lightweight Design: In some industrial control applications, weight is a critical factor. The lightweight nature of titanium alloy allows for the design of more efficient and portable industrial control equipment. This can lead to energy savings and easier installation and handling of the equipment.

6. Manufacturing and Quality Assurance

Our company, a leading manufacturer in the special steel industry since 2017, has a wealth of experience in producing high - quality titanium alloy products. We have advanced manufacturing facilities and a team of experts. Our technical staff includes 12 ASME - certified NDT Level III inspectors and 5 NADCAP - qualified engineers. They ensure that every TC10 titanium alloy bar meets the highest quality standards. We use state - of - the - art processing and testing capabilities. For example, we perform ultrasonic testing (UT) to EN 10228 - 3, which can detect internal defects as small as 0.5mm. Magnetic particle testing (MT) is also carried out for surface cracks, and these tests are certified by SGS and BV. Our products comply with international standards such as ASTM, EN, JIS, and API, ensuring their suitability for the global market.

7. Customization and Value - Added Services

We understand that different industrial control applications may have unique requirements. That's why we offer customized materials and value - added services. We can provide custom - cutting services for the bar, with the ability to cut plates up to a maximum thickness of 120mm and pipes with an outer diameter ranging from 20 - 1200mm. We can also produce welded elbows and flanges per ASME B16.9, with radiographic testing (RT) and liquid penetrant testing (PT) to ensure their quality.

In conclusion, our Precision Cut TC10 Titanium Alloy Bar is a top - notch product for industrial control parts. Its excellent material properties, high - precision manufacturing, and comprehensive quality assurance make it a reliable choice for industries around the world. Whether you are in North America, South America, Europe, Asia, or Africa, our product can meet your industrial control needs.

Send Inquiry to This Supplier

You May Also Like

-

OEM GR5/GR7 Titanium Alloy Bar for Medical Implants and Industrial Use, Custom SizeNegotiableMOQ: 100 Kilograms

-

Pure Titanium Rod TA1/TA3 High Purity for Chemical and Marine Environments, Factory PriceNegotiableMOQ: 100 Kilograms

-

GR2/GR12 Titanium Alloy Rod Rolled and Precision Ground by Factory Experts for Engineering UseNegotiableMOQ: 100 Kilograms

-

Heat Resistant TC6/TC4 Titanium Alloy Bar, Factory Manufactured for High-Temperature ApplicationsNegotiableMOQ: 100 Kilograms

-

Titanium Alloy Rod TA10/GR5 High Strength for Aerospace Parts, Factory Direct SupplyNegotiableMOQ: 100 Kilograms

-

Pure Titanium Rod GR1/GR3 Corrosion Resistant, Manufactured by Top Titanium FactoryNegotiableMOQ: 100 Kilograms

-

Medical Grade TC9/TA7 Titanium Alloy Rod for Surgical Implants and Prosthetics, Factory SupplyNegotiableMOQ: 100 Kilograms

-

GR12/GR7 Titanium Alloy Bar for Industrial Equipment, OEM Factory Supply for High-Pressure UseNegotiableMOQ: 100 Kilograms

-

Titanium Rod TA2/TA3 Factory Direct for Chemical and Food Processing, Non-Toxic MaterialNegotiableMOQ: 100 Kilograms

-

Titanium Alloy Rod GR5/GR7 Custom Size for Aerospace and Medical Applications, Factory SupplyNegotiableMOQ: 100 Kilograms