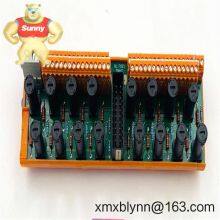

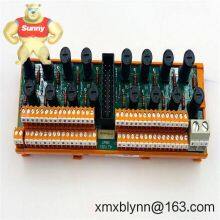

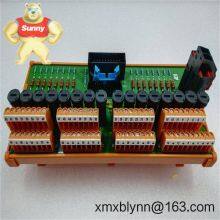

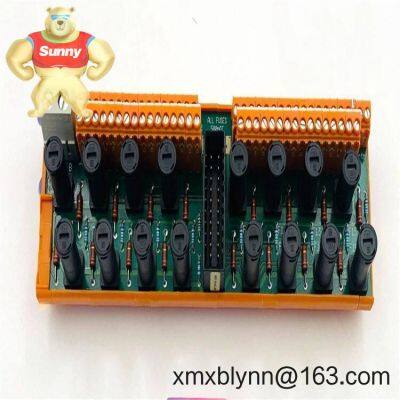

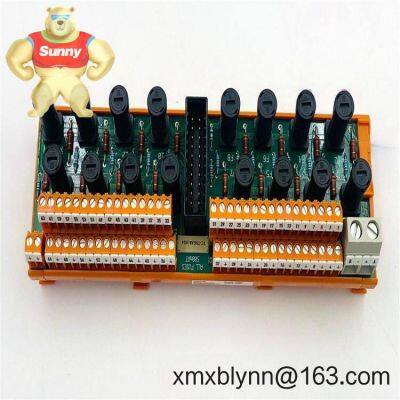

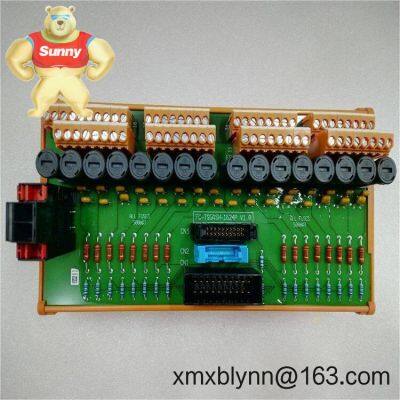

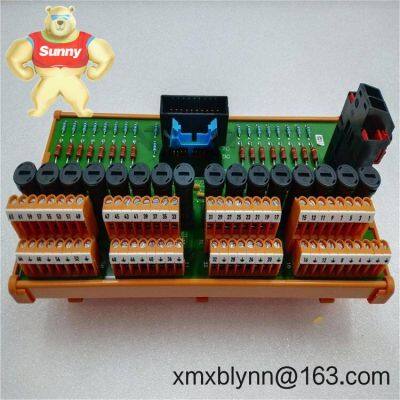

HONEYWELL FC-SDI-1624 – 16‑Channel 24 VDC Sinking Digital Input Module for Industrial PLC/SCADA I/O

The HONEYWELL FC-SDI-1624 is a 16‑channel, 24 VDC sinking digital input module designed for Honeywell’s Series C/Experion platforms. It’s typically used to bring in discrete field signals from proximity sensors, limit switches, and dry contacts, consolidating them into a clean, manageable I/O point count. From my experience, it slots in smoothly where you need reliable 24 V logic inputs, quick status diagnostics, and a neat termination layout that keeps panel wiring tidy.

Key Features16 digital inputs, 24 VDC (sinking) – Ideal for PNP sensors, pushbuttons, interlocks, and equipment permissives at standard 24 VDC control levels.

Grouped commons for clean wiring – Inputs are typically organized in groups to simplify field power distribution and troubleshooting.

Per‑channel status LEDs – Quick visual checks during commissioning and maintenance; you can spot a miswired sensor in seconds.

Noise‑robust input filtering – Debounce/filtering typically reduces nuisance transitions from contact bounce and electrical noise on long cable runs.

Series C form factor and backplane power – Integrates with the Honeywell I/O base/termination assembly (IOTA) and communicates via the platform backplane to the controller.

Clear labeling and serviceability – Wire markers, channel IDs, and accessible terminals support fast, low‑risk field changes.

Compatible with Experion/C300 architectures – Works within Honeywell’s distributed control ecosystem; no extra conversion hardware in normal cases.

| Brand / Model | HONEYWELL FC-SDI-1624 |

| Input Type | 16-channel digital inputs, 24 VDC nominal, sinking configuration (PNP field devices) |

| Power Requirements | Powered via Honeywell Series C backplane/IOTA; field 24 VDC supplied to input commons by user |

| Operating Temperature | Typically 0 to +55 °C (32 to 131 °F), non‑condensing environment |

| Communication Interfaces | Backplane I/O bus within Honeywell Series C; network access via the system controller (e.g., C300) |

| Installation Method | Mounts to the corresponding DI IOTA/termination assembly; cabinet or DIN-rail per base hardware |

| Diagnostics | Per‑channel LEDs; fault/status reporting via controller |

| Dimensions & Weight | Standard Honeywell Series C module form factor (compact width; panel depth compatible) |

Factory automation: packaging lines, conveyors, palletizers (limit switches, photoeyes, guard doors)

Process skids: compressors, pumps, dosing systems (start/stop, permissives, alarms)

Utilities and facilities: HVAC panels, water treatment, boiler/burner management interlocks

Material handling and intralogistics: diverters, sensors, jam detection

OEM machine controls where standardized 24 VDC PNP sensors are used

Proven compatibility – Designed for Honeywell Series C/Experion, reducing validation work and integration risk.

Lower installed cost – 16 inputs per module with grouped commons typically simplifies wiring and reduces terminal count.

Faster commissioning – Channel LEDs and clear labeling help techs verify I/O points quickly. One thing I appreciate is the intuitive channel layout.

Maintenance-friendly – Straightforward diagnostics and accessible terminations mean less downtime in most cases.

Support and lifecycle – Backed by Honeywell’s support ecosystem; firmware and documentation availability typically streamlines OT/IT change control.

Panel/cabinet requirements – Install on the correct Honeywell DI IOTA. Provide ventilation; keep ambient within the stated operating temperature. Maintain clearance for field wiring and service loops.

Power and wiring – Use regulated 24 VDC for field devices. Follow group commons per the IOTA diagram. For long runs, shield and ground per Honeywell wiring practices to minimize noise.

Safety practices – De‑energize field circuits before landing or moving wires. Verify polarity with a meter; check channel LEDs to confirm state.

Routine maintenance – Periodically re‑torque terminals, inspect for dust buildup, and validate critical interlocks. Keep controller and I/O firmware aligned with approved site baselines.

CE compliant; designed for industrial control environments

UL/CSA listings commonly available for Series C modules

RoHS-compliant construction

Manufacturer’s standard warranty (typically 12 months from delivery)

Honeywell DI IOTA (Input/Output Termination Assembly) – The base/termination for the FC‑SDI‑1624; provides field wiring terminals and backplane connection.

Series C controller (e.g., C300) – Hosts the I/O over the backplane and exposes points to Experion. Choose redundancy as required by your process risk profile.

24 VDC industrial power supply – Regulated, low‑ripple supply sized for all connected sensors and device loads.

Breakers/fusing and surge suppression – Protect input groups and improve resilience against switching transients.

Send Inquiry to This Supplier

You May Also Like

-

HONEYWELL FC-GMMD16 – 16‑channel Discrete I/O Module for Dependable Field Signal AggregationNegotiableMOQ: 1 Combo

-

HONEYWELL CC-TAIX11 – Series C HART Analog Input Module for Reliable 4–20 mA Data AcquisitionNegotiableMOQ: 1 Combo

-

HONEYWELL CC-GAOX11 – Series C Analog Output Module for Reliable 4–20 mA ControlNegotiableMOQ: 1 Combo

-

HONEYWELL CC-GAOX11 – Series C Analog Output Module for Reliable 4–20 mA ControlNegotiableMOQ: 1 Combo

-

HONEYWELL FC-GMDO08 – 8‑Channel Discrete Output Module for Reliable Field ActuationNegotiableMOQ: 1 Combo

-

HONEYWELL CV-DYNB-AIO – All‑in‑One Dynamic Balancing Control Valve for HVAC Hydronic LoopsNegotiableMOQ: 1 Combo

-

HONEYWELL FC-PDP-0824 – 8‑channel 24 VDC Pulse/discrete Input Module for Reliable Counting and Digital SensingNegotiableMOQ: 1 Combo

-

HONEYWELL FC-IOTA-NR24 – 24 V I/O Terminal Assembly for Reliable Low‑voltage Field ConnectionsNegotiableMOQ: 1 Combo

-

HONEYWELL CV-DINA-32NAIO – High‑density DIN‑rail Analog I/O for Machine and Process ControlNegotiableMOQ: 1 Combo

-

HONEYWELL CC-PWRN01 Power Module – Reliable Backplane Power for Series C/Experion NodesUS$ 216.00MOQ: 1 Blade