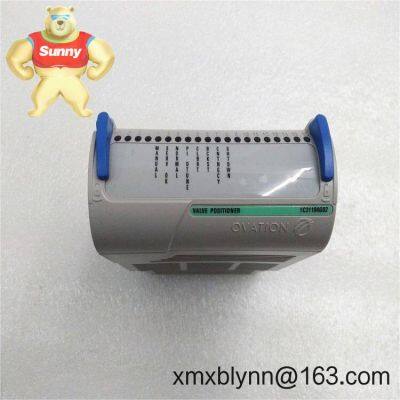

EMERSON 1C31194G03 – Ovation I/O Module for Reliable Plant Signal Interface

The EMERSON 1C31194G03 is part of the Ovation DCS I/O family, designed to bridge field signals with the control system in a stable, maintenance-friendly way. It’s typically used in process and power applications where 24/7 continuity matters—think turbines, boiler houses, water treatment trains, and balance-of-plant skids. From my experience, this model is favored as a drop-in replacement to keep legacy and current Ovation systems running smoothly with minimal re-engineering.

Native Ovation backplane compatibility – plugs directly into the standard Ovation I/O carrier to streamline replacements and expansions.

Signal conditioning on-board – designed to handle common industrial signal ranges; configuration is typically set per channel type within the Ovation framework.

Diagnostic status indication – you might notice clear module health/status through front indicators, helping techs spot issues faster.

Channel density suited to plant retrofits – in many cases supports common analog or discrete counts, keeping wiring changes minimal.

Lifecycle-friendly – aligns with Ovation spare strategies so maintenance teams can standardize inventory.

Typical isolation and noise immunity – seems to be robust against electrical noise you’ll often see around MCCs and high-power cabinets.

| Brand / Model | EMERSON 1C31194G03 |

| System | Ovation DCS I/O module (plug-in card) |

| Power Requirements | Supplied via Ovation backplane; typical low-voltage distribution (no separate field supply to the card) |

| Operating Temperature | 0 to +60 °C (typical for Ovation I/O; site conditions may apply) |

| Signal Input/Output Types | Variant-dependent within Ovation family; commonly used for analog (4–20 mA/voltage) or discrete signals |

| Communication Interfaces | Backplane bus to Ovation controller; no external comm ports on the card face in typical builds |

| Installation Method | Plug-in to Ovation I/O carrier/chassis; field wiring via associated termination assemblies |

| Dimensions & Weight | Standard Ovation card format (consult cabinet drawing for exact slot allowances) |

Plants running EMERSON Ovation—particularly power generation (coal, gas, combined-cycle), water/wastewater, and district energy—use 1C-series I/O to keep loops stable and diagnostics straightforward. I’ve also seen it in refinery utility areas, chemical auxiliaries, and metals process lines where Ovation manages balance-of-plant equipment. If you’re standardizing spares across multiple units, this module typically keeps things consistent slot-to-slot.

Minimal downtime – drop-in for existing Ovation racks with alignment to existing terminations in most cases.

Lifecycle confidence – widely deployed base, with predictable firmware/hardware revisions that maintenance teams trust.

Compatibility – integrates cleanly with Ovation controllers, engineering tools, and diagnostics, which reduces commissioning risk.

Inventory efficiency – one thing I appreciate is how standardization helps cut spare stock variety and cost over time.

Environment: Install in an Ovation-rated cabinet with adequate ventilation; maintain recommended ambient temperature and humidity.

Wiring: Use the designated field termination assemblies (FTAs) for your signal type; verify shielding and grounding to limit noise pickup.

Handling: Observe ESD precautions; follow site procedures for removal/insertion. Some sites run hot-swap, but I typically advise coordinating with operations to prevent nuisance trips.

Commissioning: Perform loop checks and point-to-point verification; if analog, confirm ranges, scaling, and any required calibration steps.

Upkeep: Keep the card area clean, check connectors for tightness during outages, and align module firmware/hardware revisions with your DCS baseline before mixing spares.

Ovation I/O hardware is typically backed by CE and UL/CSA compliance and produced under ISO 9001 quality systems. RoHS alignment is common for current revisions. Standard manufacturer warranty coverage applies; most customers I work with plan for a 12‑month minimum on spares, sometimes extended via service agreements.

Field note from a utility client: “Swapping the 1C31194G03 into our existing rack took less than an hour, including checks. The diagnostics made it easy to prove the loop health before handover.”

Send Inquiry to This Supplier

You May Also Like

-

EMERSON 1C31227G01 – Ovation I/O Module for Reliable Field Signal IntegrationNegotiableMOQ: 1 Combo

-

EMERSON 1C31233G01 – Ovation I/O Module for Dependable Field Signal InterfacingNegotiableMOQ: 1 Combo

-

EMERSON 1X00781H01L – Ovation DCS I/O Module for Reliable Plant Signal IntegrationNegotiableMOQ: 1 Combo

-

EMERSON 38B5786X132 – OEM Mounting/Linkage Assembly for Valve Positioners and ActuatorsNegotiableMOQ: 1 Combo

-

Emerson 5X00034G01 – Reliable Ovation DCS I/O Module for Plant AutomationNegotiableMOQ: 1 Combo

-

Emerson 5X00058G01 – HART Analog Input Module for Ovation DCSNegotiableMOQ: 1 Combo

-

EMERSON 5X00109G01 HART Analog Input Module – Smart 4–20 mA Acquisition With HART DiagnosticsNegotiableMOQ: 1 Combo

-

EMERSON 5X00109G02 Analog Input Module – Stable, Accurate Process Signal Acquisition for Ovation DCSNegotiableMOQ: 1 Combo

-

EMERSON 5X00119G01 – 8‑Channel RTD Input Module for Precision Temperature Monitoring in Ovation SystemsNegotiableMOQ: 1 Combo

-

EMERSON 5X00226G01 Relay Output Module – Reliable Dry-contact Switching for Ovation DCSNegotiableMOQ: 1 Combo