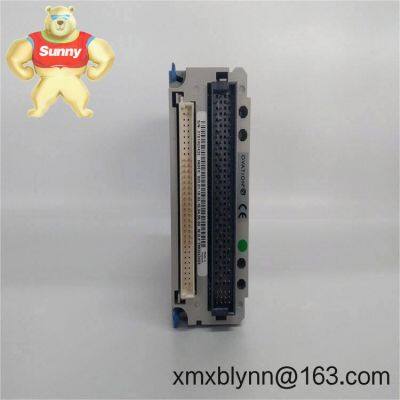

EMERSON 1C31124G01 – Ovation I/O Module for 24 VDC Discrete Signal Collection

The EMERSON 1C31124G01 is an Ovation DCS I/O module commonly used to bring 24 VDC discrete (on/off) field signals into the control system with plant-grade reliability. From my experience, it’s selected for turbines, balance-of-plant, and water process areas where you need clean, time-accurate status inputs with minimal downtime. One thing I appreciate is how it fits straight into the Ovation I/O carrier and works with standard field termination assemblies (FTAs), which typically keeps retrofits straightforward and fast.

Ovation System Compatibility – Designed for EMERSON Ovation racks/carriers, enabling drop-in replacement and quick commissioning.

24 VDC Discrete Inputs (typical) – Suits common plant signals like limit switches, permissives, motor starters, and interlocks.

Channel Density – Up to 32 channels per card in many installations, depending on the FTA and revision; confirm against your BOM.

Filtering & Debounce – Input conditioning helps reject contact bounce and electrical noise so your logic isn’t chasing false transitions.

Time-Stamp / SOE Support – Certain revisions support sequence-of-events capture for fast diagnostics during trips and starts.

Redundancy Friendly – Works in redundant controller architectures used across power and water facilities.

Hot-Swap Serviceability – Typically replaceable under power on the I/O carrier to shorten maintenance windows.

FTA Wiring Options – Supports standard Ovation FTAs for clean cabinet wiring and easier field terminations.

Status LEDs – Quick visual diagnostics during commissioning and fault finding.

| Brand / Model | EMERSON 1C31124G01 |

| System Platform | Ovation Distributed Control System (I/O carrier based) |

| Power Requirements | Backplane powered via Ovation I/O carrier (no external feed to the module) |

| Signal Input/Output Types | 24 VDC discrete inputs (sink/source detection varies by FTA and revision) |

| Channel Count | Typically up to 32 DI channels/card (verify against your exact part revision) |

| Communication Interfaces | Proprietary Ovation I/O bus via carrier; engineered for tight controller integration |

| Installation Method | Plug-in module on Ovation I/O carrier; field wiring via compatible FTAs |

| Dimensions & Weight | Standard Ovation plug-in card format; contact for exact outline if required for cabinet layout |

| Operating Temperature | Industrial range; 0–55°C typical in many installations (check datasheet for your revision) |

Power generation: turbine auxiliaries, boiler/balance-of-plant permissives, MCC status, breaker feedback, and trip circuits.

Water & wastewater: pump start/stop feedback, valve limit switches, level switch alarms, and interlocks.

Oil & gas / petrochemical: skid-mounted packages, compressor panels, ESD inputs, and process interlocks.

Metals, mining & paper: safety gates, conveyor status, jam detection, and motor protection relays.

Drop-in Fit – Keeps your Ovation architecture intact; typically no panel rebuilds or re-landing of wires.

Lower Downtime – Hot-swap capability and diagnostic LEDs make fault isolation faster in most cases.

Lifecycle Confidence – Stable platform with long service history in utilities; widely supported in the field.

Scalable – Broad FTA options to match sink/source wiring, marshalling practices, and plant standards.

Cabinet Environment – Install in a clean, ventilated control cabinet; maintain ambient within the specified temperature range and avoid corrosive atmospheres.

Wiring Practices – Use shielded, twisted-pair for long runs; land field wiring on the appropriate Ovation FTA; keep high-voltage and control wiring segregated.

Grounding – Bond shields at a single point per site standard to minimize ground loops; ensure cabinet earth continuity.

Hot-Swap Procedure – Follow site LOTO and Ovation replacement steps; verify channel status via LEDs and the Ovation workstation.

Routine Checks – Periodically inspect terminal tightness, clean dust with dry air, and validate input debounce/filter settings.

Firmware/Config – Where applicable, align module configuration and any firmware with your controller revision control policy.

Typically conforms to industrial safety and EMC standards; CE and UL/cUL are common for Ovation hardware.

RoHS compliance is common across modern Ovation module revisions; confirm per lot if you need documentation.

Manufacturer’s warranty applies by region and program; 12-month coverage is typical for newly supplied modules.

If your application requires a specific channel type (e.g., dry contact vs. 24 VDC proximity) or SOE time-stamping, share your current rack layout and FTA part numbers—I’ll match the exact 1C31124G01 revision so it behaves the way your logic expects.

Send Inquiry to This Supplier

You May Also Like

-

EMERSON 1C31194G02 – Ovation DCS I/O Subsystem Module for Reliable Plant ControlNegotiableMOQ: 1 Combo

-

EMERSON 1C31194G03 – Ovation I/O Module for Reliable Plant Signal InterfaceNegotiableMOQ: 1 Combo

-

EMERSON 1C31197G05 – Ovation DCS Module for Reliable I/O and System InterfaceNegotiableMOQ: 1 Combo

-

EMERSON 1C31201G01 – Ovation I/O Module for Dependable Field Signal IntegrationNegotiableMOQ: 1 Combo

-

EMERSON 1C31205G01 – Ovation Rack I/O Module for Dependable Process ControlNegotiableMOQ: 1 Combo

-

EMERSON 1C31206G01 Ovation I/O Module – Stable Signal Interfacing for Critical Process ControlNegotiableMOQ: 1 Combo

-

EMERSON 1C31223G01 – Ovation I/O Module for Dependable Process Signal AcquisitionNegotiableMOQ: 1 Combo

-

EMERSON 1C31227G01 – Ovation I/O Module for Reliable Field Signal IntegrationNegotiableMOQ: 1 Combo

-

EMERSON 1C31233G01 – Ovation I/O Module for Dependable Field Signal InterfacingNegotiableMOQ: 1 Combo

-

EMERSON 1X00781H01L – Ovation DCS I/O Module for Reliable Plant Signal IntegrationNegotiableMOQ: 1 Combo