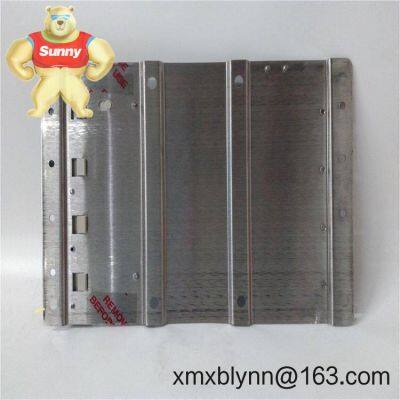

Schneider Electric 140XBP00400 – Modicon Quantum 4‑Slot Backplane for Compact PLC Racks

The 140XBP00400 is the 4‑slot backplane for Schneider Electric’s Modicon Quantum platform, ideal when you need a reliable, space‑saving rack for a CPU, power supply, and a small set of I/O or network modules. It’s typically used in smaller machine cells, pilot systems, or as a local expansion rack where cabinet space is at a premium.

From my experience, it’s a clean way to keep a Quantum node lean without sacrificing serviceability or module compatibility. You keep the proven Quantum stability while avoiding an oversized chassis for just a handful of modules.

4-slot Quantum form factor – Fits a 140CPS power supply, 140CPU, and up to two I/O/communication modules in a compact footprint.

Native Modicon Quantum backplane bus – Works with standard 140‑series modules (CPU, power, I/O, and comms) for straightforward integration.

Panel-mount ready – Designed for control cabinet mounting; no special frames required, typically lighter than large racks.

Stable 5 V bus distribution – Bus power provided by the installed 140CPS power supply; capacity depends on the PSU selected (no separate backplane supply needed).

Service-friendly layout – Clear slot arrangement (power supply at the left, CPU adjacent) helps with wiring discipline and quick maintenance.

Backwards compatibility – Suits installed-base upgrades and spare-part strategies where Quantum remains the site standard.

| Brand / Model | Schneider Electric Modicon Quantum – 140XBP00400 |

| Series / Type | Quantum backplane (4 slots) |

| Power Requirements | Powered via 140CPSxxx power supply module; distributes 5 V bus to installed modules |

| Slots / Capacity | 4 total (typical arrangement: PSU, CPU, 1–2 I/O or comm modules) |

| Operating Temperature | Typically 0 to 60 °C (non‑condensing environment) |

| Signal I/O Types | Determined by installed 140‑series I/O modules (digital, analog, specialty) |

| Communication Interfaces | Local Quantum backplane only; external networks handled by modules (e.g., 140NOE, 140NOC) |

| Installation Method | Panel/cabinet mounting with grounding; not DIN-rail |

| Compliance | CE, UL, CSA; RoHS compliant in most cases |

This backplane is a good fit for compact automation nodes that still need Quantum-grade reliability. You might notice it used frequently where a small but robust controller footprint is preferred.

OEM machine skids with limited cabinet space

Water & wastewater lift stations and small process cells

Power generation auxiliaries and sub‑systems

Oil & gas well pads, metering skids, and compact RTU‑style cabinets

Brownfield sites maintaining an installed Quantum standard

Right‑sized footprint – Avoids paying for and populating unused rack slots; helpful when enclosure depth is tight.

Compatibility and longevity – Supports a wide range of 140‑series modules, aiding spares strategy and minimizing re‑engineering work.

Lower lifecycle cost – Fewer modules to power and cool; easier to maintain. In many cases, it reduces downtime during servicing.

Clear migration path – Many sites keep the 4‑slot as a local node while planning phased modernization, which seems to be the least disruptive approach.

“We swapped a bulky 8‑slot rack for the 140XBP00400 in a dosing skid—same CPU and comms, half the space, and wiring was far cleaner.” — Maintenance Supervisor, food & beverage plant

Installation & MaintenanceCabinet & mounting – Mount on a rigid backplate with proper earthing. Provide clearance for wiring and module removal. Not intended for DIN rail.

Ventilation – Maintain airflow around the rack; keep ambient within the typical 0–60 °C range and below 95% RH non‑condensing.

Power sizing – Choose a 140CPS power supply with adequate 5 V current headroom for all installed modules; verify load with Schneider’s sizing guidelines.

Wiring discipline – Separate power and signal wiring; use shielded cables where required by I/O modules; tighten all grounding points.

Safety & ESD – De‑energize before adding/removing modules; use ESD protection when handling boards and connectors.

Routine checks – Inspect backplane connectors for dust; clean with dry air. Firmware updates apply to CPU/comms modules, not the backplane itself.

CE and UL/CSA certifications (typical for Modicon Quantum hardware)

RoHS compliance for environmental requirements

Manufacturer warranty: typically 18 months from shipment (standard Schneider Electric policy)

Note: If you anticipate growth beyond two I/O/communication modules, consider moving to 8, 10, 12, or 16‑slot Quantum backplanes (e.g., 140XBP00800, 140XBP01000, 140XBP01200, 140XBP01600) to avoid rework later.

Send Inquiry to This Supplier

You May Also Like

-

Schneider Electric MC91 HESG440588R4: Industrial Power Supply Keeping Your Lines RunningUS$ 5300.00MOQ: 1 Blade

-

81001-450-53-R Inverter Module of the Thyristor Mainboard Progress in the Level of TechnologyNegotiableMOQ: 1 Bag

-

MAX-4/11/03/128/99/1/1/00 Servo Driver Have RelevanceNegotiableMOQ: 1 Bag

-

140CPU67861 Distributed Control System Ensure That the Health Status of the System is ReportedNegotiableMOQ: 1 Bag

-

140CPU65160 Central Processing Unit Unified Security ProcessorNegotiableMOQ: 1 Bag

-

140CPU67160C ProcessorNegotiableMOQ: 1 Bag

-

MC-4/11/10/400 PowerDrive Motion ControllerUS$ 7042.00MOQ: 1 Pallet

-

Schneider Electric 140ACO13000 (often Listed as 140AC013000) – 16‑Channel Analog Current Output for Modicon Quantum ControlNegotiableMOQ: 1 Combo

-

Schneider Electric 140ACI03000C – Modicon Quantum Analog Current Input for 0/4–20 mA Process SignalsNegotiableMOQ: 1 Combo

-

Schneider Electric 140ACI04000 – 4‑Channel Analog Current Input for Modicon Quantum Process ControlNegotiableMOQ: 1 Combo