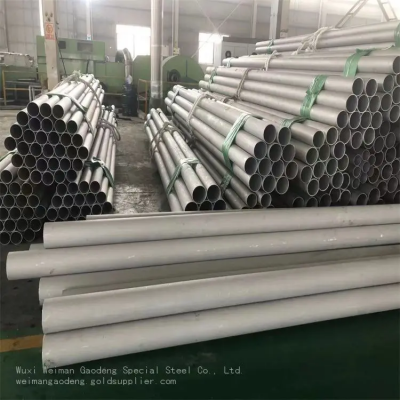

Aerospace Grade Stainless Steel Pipes SUS329J1/254SMO/F44/S31254 Professional Manufacturer for Aerospace Hydraulic Tubing

Product Overview

Our Aerospace Grade Stainless Steel Pipes, including SUS329J1, 254SMO, F44, and S31254, are specifically designed for aerospace hydraulic tubing applications. These pipes are the result of advanced manufacturing techniques and strict quality control, meeting the high - standards required in the aerospace industry.

Material and Surface Treatment

- Material Composition: The SUS329J1, 254SMO, F44, and S31254 stainless steel grades used in these pipes offer exceptional corrosion resistance, high strength, and excellent mechanical properties. For example, 254SMO is a high - alloy austenitic stainless steel with a high content of chromium, molybdenum, and nitrogen, which provides outstanding resistance to pitting and crevice corrosion in aggressive environments.

- Surface Treatment: The pipes undergo a polished surface treatment. This not only gives them an aesthetically pleasing appearance but also enhances their corrosion resistance. The smooth surface reduces the risk of debris accumulation and makes the pipes easier to clean, which is crucial in aerospace applications where cleanliness is of utmost importance.

Manufacturing Technique

- Hot Rolled Process: These pipes are manufactured using the hot - rolled technique. Hot rolling involves heating the steel above its recrystallization temperature and then passing it through rollers to achieve the desired shape and dimensions. This process improves the mechanical properties of the steel, such as its ductility and toughness. It also ensures a more uniform grain structure, which is essential for the reliable performance of the pipes in aerospace hydraulic systems.

Shape and Standard

- Shape: The pipes are round in shape, which is the most common and practical shape for hydraulic tubing. The round shape provides uniform stress distribution, allowing the pipes to withstand high - pressure hydraulic fluids without deformation.

- Standard: They comply with the ASTM standard. ASTM standards are widely recognized and respected in the global market, ensuring that our pipes meet the strict quality and performance requirements set by the industry. This compliance also makes it easier for our international customers to integrate our pipes into their existing aerospace systems.

Applications in Aerospace Hydraulic Systems

- Hydraulic Fluid Conveyance: These pipes are primarily used for conveying hydraulic fluids in aerospace hydraulic systems. They can handle high - pressure fluids, ensuring the smooth and efficient operation of various hydraulic components such as actuators, valves, and pumps.

- Reliability and Safety: In aerospace applications, reliability and safety are non - negotiable. Our pipes are designed to withstand the harsh conditions of flight, including extreme temperatures, vibrations, and pressure fluctuations. Their high - strength and corrosion - resistant properties ensure long - term performance and reduce the risk of system failures, which is crucial for the safety of aircraft and their passengers.

Company Capabilities and Support

- Manufacturing Expertise: As a professional manufacturer, we have been in the industry since 2017. Our company, with a team of 11 - 20 experienced salespersons, has an annual export share ranging from US$5 Million - US$10 Million. Our production facilities are equipped with advanced machinery and technology, allowing us to produce high - precision pipes with tight tolerances.

- Customization and Value - Added Services: We specialize in high - precision special steel solutions. We can provide customized materials and value - added services to meet the specific needs of our global customers. Whether it's a unique size, a special surface finish, or a particular alloy composition, we have the capabilities to fulfill those requirements.

- Quality Assurance: Our company has a comprehensive quality control system in place. We conduct various tests, including ultrasonic testing (UT) to EN 10228 - 3 to detect internal defects as small as 0.5mm and magnetic particle testing (MT) for surface cracks, which are certified by SGS and BV. This ensures that every pipe leaving our factory meets the highest quality standards.

- Logistics and Delivery: We have strategically located warehouses in Wuxi, enabling us to provide 48 - hour delivery to major Chinese ports. This rapid logistics service ensures that our customers can receive their orders in a timely manner, minimizing production delays.

Company History and Team

- Company History: Our journey from an R & D - focused startup to a global special steel solution provider has been a remarkable one. Since our foundation in 2003, we have continuously upgraded our technology and expanded our capabilities. In 2017, we obtained important certifications such as ISO 9001:2015, API 5L, and EU PED, which allowed us to enter the international market. In 2019, we partnered with Germany's DMV Mannesmann on nickel - based alloy supply, further enhancing our global presence.

- Expert Team: Our leadership team consists of experienced professionals. Mr. Sang Le, our CEO, has over 20 years of experience in the special steel industry and is well - versed in EU/US market compliance. Dr. Li Wei, our Chief Metallurgist, holds a PhD in Materials Science from Tsinghua University and specializes in creep - resistant alloys and titanium metallurgy. Our technical staff includes 12 ASME - certified NDT Level III inspectors and 5 NADCAP - qualified engineers, ensuring the high - quality production and inspection of our aerospace - grade stainless steel pipes.

In conclusion, our Aerospace Grade Stainless Steel Pipes SUS329J1/254SMO/F44/S31254 are the ideal choice for aerospace hydraulic tubing applications. With their excellent material properties, advanced manufacturing techniques, and strict quality control, they offer reliable performance and long - term durability in the demanding aerospace environment.

Send Inquiry to This Supplier

You May Also Like

-

Heat Resistant S43000 Seamless Tubing Industrial Grade Stainless Steel Seamless PipeNegotiableMOQ: 1 Kilogram

-

High Strength 1.4016 Ferritic Tubing Corrosion Proof Ferritic Stainless Steel PipeNegotiableMOQ: 1 Kilogram

-

Polished Surface 1.4742 Stainless Steel Tubing Custom Length Stainless Steel PipeNegotiableMOQ: 1 Kilogram

-

Wear Proof TP446-1 Seamless Tubing Industrial Use Stainless Steel Seamless PipeNegotiableMOQ: 1 Kilogram

-

Corrosion Resistant TP446-2 Ferritic Tubing High Temperature Ferritic Stainless Steel PipeNegotiableMOQ: 1 Kilogram

-

Oxidation Proof S44600 Stainless Steel Tubing Precision Cut Stainless Steel Seamless Steel PipeNegotiableMOQ: 1 Kilogram

-

High Strength 1.4749 Seamless Tubing Heat Resistant Stainless Steel Seamless PipeNegotiableMOQ: 1 Kilogram

-

Custom Diameter TP439 Ferritic Tubing Wear Resistant Ferritic Stainless Steel PipeNegotiableMOQ: 1 Kilogram

-

Corrosion Proof S43035 Stainless Steel Tubing Industrial Grade Stainless Steel PipeNegotiableMOQ: 1 Kilogram

-

Polished Surface 1.4510 Seamless Tubing Industrial Application Stainless Steel Seamless PipeNegotiableMOQ: 1 Kilogram