Hangzhou ROYAL Packing Machinery Co.,Ltd.

Tel:0086-571-85829052-8303 Fax:0086-571-85829153

Mobile/WhatsApp/WeChat: 0086-13317226817

Email: sales01@royal-packing.com

Contact Person: Yvonne Qiao

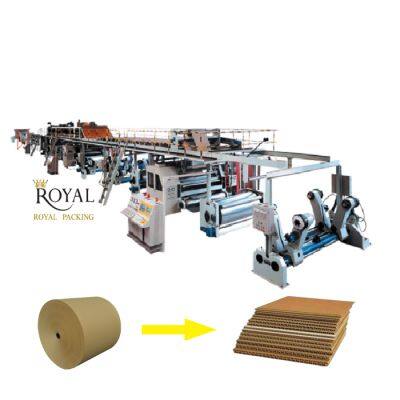

HIGH SPEED MJF1800-120 5 LAYER

CORRUGATED PAPERBOARD PRODUCTION LINE

We are the biggest manufacturer for corrugated packaging machinery in North of China.

Our main products are the complete corrugated paperboard production line, flexo printer slotting & die cutting machine, carton making and converting machine. The Complete Corrugated production Line is composed of Hydraulic Mill Roll Stand, High Speed Single Facer, NC Slitter Scorer Machine, NC Cut-Off Machine, Stacker as well as Rotary Slotting Machine, Folder Gluer Machine etc.

Our company has advanced technology, perfect design and reliable guarantee system for machines. Based on honesty and credit, we are committed to provide our customer with high quality products and favorable prices and best service. We welcome you to visit our company and give us your valuable guidance

※Main Technical Parameters and Requirements in production line

Type: MJF1800-80-5 layer corrugated paperboard production line

1 | Effective width | 1800mm | 2 | Design produce speed | 120m/min | |||

3 | Three layer work speed | 100m/min | 4 | Five layer work speed | 80m/min | |||

5 | Seven layer work speed | ------------------- | 6 | |||||

7 | Longitudinal separation accuracy | ±1mm | 8 | Cross-cutting precision | ±1mm | |||

Note | Speed the above targets required to achieve: effective width 1800mm, Comply with the following standards and ensure the paper's equipment condition 175 ℃ heating surface temperature. | |||||||

Top paper index | 100g/㎡--180g/㎡ Ring crush index(N.m/g) ≥8 (Water containing8-10%) | |||||||

Core paper index | 80g/㎡--160g/㎡ Ring crush index(N.m/g) ≥5.5 (Water containing8-10%) | |||||||

In paper index | 90g/㎡--160g/㎡ Ring crush index(N.m/g) ≥6 (Water containing8-10%) | |||||||

9 | Flute combination | |||||||

10 | Steam requirement | The maximum pressure 16kg/cm2 | Common pressure10-12kg/cm2 | Steam boiler 2000kg/Hr | ||||

11 | Electricity demand | AC380V 50Hz 3PH | Total power≈100KW | Running Power≈120KW | ||||

12 | Compressed air | The maximum pressure 9kg/cm2 | Common pressure4-8kg/cm2 | use1m3/min | ||||

13 | space | ≈Lmin66m*Wmin11m*Hmin6m(The actual drawing to provider to provide audited prevail) | ||||||

Customer-owned section |

1. Steam heating system: proposal with 4000Kg / Hr of a steam boiler pressure: 1.25Mpa steam pipeline. |

2. Air compressed machine, air pipeline, glue conveying pipe. |

3. Power supply, wires connected to the operation panel and line pipe. |

4. Water sources, water pipelines, buckets and so on. |

5. Water, electricity, gas flush mounting civil foundation. |

6. Test with the base paper, corn starch (potato) , Industrial use caustic soda, borax and other material. |

7. Oil equipment, lubricating oil, hydraulic oil, lubricating grease. |

8. Installation, commissioning of food, accommodation. And provide installers with the installation. |

More Introduction of the machines

Hydraulic Mill Roll Stand

Machine Introduction:

*Swing type.

*Max. paper roll dia.: 1500mm

length: 900-1800mm

*Clamping paper roll, moving right-left, arms up-down and paper roll rotation is hydraulic operated.

*Support two paper rollers in the meantime, one is working, and another is for spare part.

* Adopts “Spring clutch”.

* Paper tension controlled by pneumatically operated disc brake, setting the tension easily.

Fingerless Type Single Facer MJSF280

Machine Introduction:

*Design speed: 120m/min.

*Corrugated rollers made of 48CrMo alloy steel, with heat treatment for hardness HRC58-60, surface plated with chrome treatment.

*corrugating roller: dia.290mm with a drum.

*Press roller: dia. 320mm. with drum.

*Flute paper preheater diameter: 400mm, Inner paper preheater diameter: 600mm.

* Vacuum suction Fingerless design provides perfect flute formation in high speed manufacturing.

* Gimbal driver system. Individual immersion oil gear type drive box, separating dynamic vibrations improve running stability, easy and fast for maintenance.

*Gluing roller: surface is embossed with netting design and chrome plated.

*Adjustment of upper corrugated roller, pressure roller and glue roller controlled by pneumatic system.

*With preheating and preconditioning rollers.

Triple Preheater

Machine Introduction:

* Accurate grinding and chromed the surface of heating roller and wrap roller, smooth and shining.

*Heating roller adopts professional manufacturer product, passed the nation pressure vessel text.

*Heating roller and wrap roller adopts plating treatment.

*Motorized wrap angle can be suit for different speed; Exact preheating result can be adjusted, preheating area be adjusted by electrical motor

*Wrap roller: 2sets, one fix roller, and other one floating roller.

*Adopts butterfly seal structure on two sides, save the steam and improve heating efficiency.

*Adopts special sealing method, follow firstly grade sealing method in China, passed the China sealing text, with certificate.

Overhead Bridge

Structural feature:

Independent frequency motor lifting mechanism, PVC conveyor belt, a single watt of cardboard into a wavy rule stable.

All roller surface after grinding hard chrome plated.

Vacuum adsorption tension control,5-inch suction tube,add regulator valve,air volume stepless adjustable air volume.

Electric corrective devices II sets,correction baffle double guide column positioning,Screw Driver,positioning fast and accurate , smooth running.

GM-15 Duplex Gluer Machine

Machine Introduction:

-High precision engraved applicator roll ensure uniform glue application and less glue consumption

-Pressing roller type with high manufacture efficiency, pneumatic control, easy and fast to operate.

-Auto-circulating glue feeding system is applied to avoid glue depositing

-Independent inverter motor control driver.

-The self-preheating device speeds up glue gelling and create a stronger glue bond

DOUBLE FACER

Machine Introduction:

*Heating plate: 1900mm(L)×600mm(W)×180mm(H)×12pcs

made of steel plate, polish plate.

*Steam pipe for heating plate, divided into 6 sections respectively.

*The heating temperature for each section can be controlled independently.

*For adjusting the tension of upper cotton belt with: one set pneumatic adjusting device, air cylinder: dia.160mmx250mm stroke.

*For adjusting the tension of lower cotton belt with: one set manual adjusting device.

*For guiding the upper cotton belt with: one set electric adjusting device.

--DRIVE ROLL STAND 1 SET

THIN BLADE SLITTER SCORER

SPECIFICATION

Machine Introduction:

-This type of machine is specially for the assembly line instead of old type slitter scorer machine.

-Ensuring synchronization running with the assembly line

-To slitting carton side is tidy,straight,smooth and non-crushable.

-The blades can be sharpened either manually or automatically.

-Each blade can be controlled individually.

-Colorful touch screen operation monitor,easy operation and visual monitor.

-Automatic anti-deviating,. the whole machine can be move left and right. to reduce much more waste products

N.C CUT OFF

Machine Introduction:

--Machine speed: 120m/min.

--Cutting length: 500mm-9999mm.

--Cutting precision:±1mm.

--Uses the independent oil pump and the filter coordinates two groups of copper tubes to distribute in various gears position for the oil,the lubrication and cooling.

--Helical knife structure,type sawtooth knife,decrease cutting obstruction,low noise.

--Balance treatment:high quality alloy steel for blade shaft,which helps to keep it good stability.

--Sun-shape wheels press cardboard in the front and the rear conveyer.The transporting is stable and with even pressure,which avoid jam caused or broken cardboard.

--This type of Cut-off just consume the one of third energy compare with the common cutter with its especial structure,economize above 70% energy to get more money.

--Exact and adjustable on gap gear assure knife-edge joggle exactly.running balanceable.

--Computer system to keep order. Man-machine conversation system NC. automatic adjust cutting speed by cardboard specification and machine.The screen display various production message.Can consult,modification,superaddition and cancel order during running machine.

--Germany Serve control system inside of cabinet, to keeping the machine running fast and stable

Automatic Paper Sheet Delivery Stacker

※ZJZ glue station system

※Structural features:

★provide the starch adhesive to the corrugated single facer ,two glue machine and some other gluing equipment.

★Horizontal glue machine can meanwhile matched withmain body glue and carrier glue, and mixing, glue large。

★Making room storage barrels adhesive solution was to use the glue pump rubber equipment storage barrels, adhesive solution for equipment。

★Storage barrels, plastic barrels with mixing device, avoid glue solution precipitation agglomerate。

★System unit with carrier vessel, main tank, storage tank, and send the glue pump, the back glue pump, etc。

★glue system adopt glue cycle,rest glue go back to the glue square cylinder,Liquid level float automatic control,the back glue a bucket of glue liquid being beaten back with glue equipment storage bucket,cycle for glue,Save the glue solution,prevent the glue solution in the rubber plate pasting and caking precipitation.

★Work has been completed, the residual gum dividend total pipeline with rubber equipment rubber pumped back rubber room storage barrels, for next time use。

★Responsible for technical guidance, teaching adhesive dispensing process。

※technical parameters:

1、Horizontal body glue mixer: one 2, Carrier glue mixer:one

3, Storage glue mixer: one 4, Plastic buckets on double coater: one

5, Two coating machine back plastic buckets :one 6, Plastic buckets on single machine :two

7, Single machine back plastic buckets: two 8, Lose glue dispensing pumps: four

※glue barrel diameter parameters:

1, Horizontal body glue mixer:1250mm×1000mm×900mm

2, Carrier glue mixer diameter: ¢800mm×900mm

3, Diameter plastic bucket on Double Glue:¢800mm×1000mm Plastic buckets on single machine:¢800mm×1000mm

4, Storage tank diameter: ¢1200mm×1200mm

※Power motors and electrical parameters:

1, Horizontal body glue mixer: 3KW 380V 50Hz

2, Carrier glue mixer: 2.2KW(Ordinary three-phase) 380V 50Hz

3, output plastic pump motor : 2.2KW(Ordinary three-phase) 380V 50Hz

4, Storage Tank Motor 1.5KW(Ordinary three-phase) 380V 50Hz

※Mainly purchased parts, raw materials and origin:

Name of main parts | Brands or place of origin | Material and type |

motor | Hebei hengshui yongshun | |

Lose glue dispensing pumps | Hebei botou | |

Skeleton profiles | tanggang |

※ZQ steam system

※Structural features:

★Production line for hot heating energy delivery device to maintain a stable operating temperature。

★All units are designed to be independent small unit for the steam system, segmented temperature control, energy saving, easy to adjust。

★By adjusting the steam pressure monitor dial to exercise control over the operating temperature, and a pressure。

★Each group has a hydrophobic unit emptying bypass, when rapid shutdown cooling equipment。

★Float trap 1/2 metal hose and connect the bypass valve, plug valve injection。

★Between the piping system and the rotary heating member in order to achieve a flexible metal hose connection, to extend the service life of the rotary joint。

★All steam pipes are made of seamless steel tubes, to ensure safety for use under normal pressure。

※technical parameters:

1, steam consumption:about2.5-3T/h

2, Equipped with boiler:4t/h

3, Equipped with boiler pressure:1.25Mpa Pipe temperature:170—200℃

ROYAL PACKING Machinery

Yvonne Qiao

Send Inquiry to This Supplier

You May Also Like

-

End-to-End 5 Ply Corrugated Board Production LineUS$ 1725000 - 3000000MOQ: 1 Unit

-

High Speed 5ply Corrugated Board Cardboard Box Plant Production Line Five Layer Corrugated Cardboard Production LineUS$ 1725000 - 3000000MOQ: 1 Unit

-

High Speed Single Facer Square Corrugated Cardboard Production Line, Single Facer Corrugated MachineUS$ 25500 - 35500MOQ: 1 Unit

-

Corrugated Single Facer Machine 2 Ply Single Facer Line Corrugated Cardboard Making Single Wall Cardboard Production LineUS$ 25500 - 35500MOQ: 1 Unit

-

High Speed Single Facer Square Corrugated Cardboard Production Line, Single Facer Corrugated MachineUS$ 25500 - 35500MOQ: 1 Unit

-

Single Facer Machine for Corrugated Paperboard, Corrugated Paper Making MachineUS$ 25500 - 35500MOQ: 1 Unit

-

Single Facer Machine for Corrugated Paperboard, Corrugated Paper Making MachineUS$ 25500 - 35500MOQ: 1 Unit

-

High-Speed Single Facer Corrugated Cardboard Production Line | Automatic 3/5/7 Ply Machine | Factory Direct SaleUS$ 25500 - 35500MOQ: 1 Unit

-

Efficient Single Facer Machine for Corrugated Paperboard | 2 Ply Single Wall Cardboard Making Production LineUS$ 25500 - 35500MOQ: 1 Unit

-

Hot Sale Automatic 5 Layer Corrugated Carton Line | Low Price High-Speed Single Facer Corrugated MachineUS$ 25500 - 35500MOQ: 1 Unit