Material

Other, Global universal model

Certification

CE

Function

Other, Global universal model

Condition

New

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

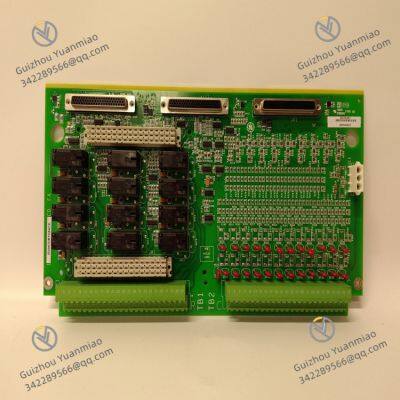

The GE IS200TDBTH6ACD is a specialized analog/digital hybrid Input/Output (I/O) terminal board engineered exclusively for GE’s Speedtronic Mark VIe and Mark VI control systems—core platforms deployed in power generation (gas/steam turbines), oil & gas processing, and heavy industrial operations. Unlike signal-processing modules that handle data computation, this terminal board acts as the "physical interface bridge" between field devices and the control system: it terminates wiring from on-site sensors/actuators, conditions raw signals to eliminate noise, and routes them to the Mark VIe/VI’s central I/O modules (e.g., IS200IBDHG1A for analog signals, IS200DBDHG1A for digital signals). Its design emphasizes industrial durability, signal reliability, and maintenance efficiency, making it essential for stable data transmission in harsh environments characterized by high vibration, electromagnetic interference (EMI), and extreme temperatures.

I. Basic Information & Core Positioning1. Model Naming Interpretation

GE’s Mark VIe/VI terminal boards follow a standardized naming system to convey system compatibility, functionality, and configuration. The breakdown of IS200TDBTH6ACD is as follows:

IS200: Hardware platform prefix for Mark VIe/VI I/O terminal products, distinguishing it from the older Mark V series (DS200 prefix). The "IS" abbreviation stands for "I/O System," confirming alignment with the Mark VIe/VI’s distributed I/O architecture.

TDBT: Functional code defining the board’s role:

"T" = "Terminal" (primary function: physical termination of field wiring),

"DB" = "Dual Signal Compatibility" (supports both analog and digital signal types),

"T" = "Enhanced Signal Conditioning" (integrates built-in filtering and surge protection for raw field signals).

H6: Configuration identifier specifying channel count and type:

"H" = "Hybrid I/O" (mix of analog and digital channels, not single-type),

"6" = Total of 6 active I/O channels (4 analog input channels + 2 configurable digital input/output channels).

ACD: Hardware revision and environmental rating:

"A" = 1st production revision (subsequent revisions like "B" improve terminal block corrosion resistance for marine/offshore use),

"C" = "Industrial-Grade Vibration Resistance" (compliant with IEC 60068-2-6 vibration standards),

"D" = "Extended Temperature Range" (supports broader operating temperatures compared to standard "C"-rated boards).

2. Core Application Scenarios

As a hybrid I/O terminal board, the IS200TDBTH6ACD is tailored to scenarios requiring centralized, protected signal termination between field devices and the Mark VIe/VI control system. Key use cases include:

Gas Turbine Auxiliary Monitoring: Terminates signals from turbine auxiliary components, such as lubricating oil pressure sensors (4-20mA analog input), coolant flow switches (dry-contact digital input), and bearing temperature transmitters (Pt100 RTD analog input). Conditioned signals are routed to the Mark VIe controller for real-time health monitoring and early fault detection.

Steam Turbine Valve Feedback: Connects to steam turbine governor valve position sensors (0-10V analog input) and valve limit switches (NO/NC digital input). It ensures the control system receives accurate valve status data to adjust steam flow, maintain load stability, and prevent over-speed events.

Oil & Gas Compressor Sensing: In onshore/offshore compressors, it terminates high-pressure sensor signals (4-20mA) and emergency shutdown (ESD) switch signals (digital input). Built-in surge protection withstands voltage spikes from lightning or motor startup, safeguarding downstream I/O modules.

Power Plant Boiler Feedwater Control: Interfaces with feedwater pump pressure transmitters (analog input) and pump start/stop status switches (digital input). Filtered signals enable the control system to regulate feedwater flow precisely, preventing boiler dry-firing or over-pressurization.

II. Key Technical Specifications1. I/O Channel Performance

| Channel Type | Specifications |

|---|

| Analog Input (AI) Channels | - Quantity: 4 independent, configurable channels (CH1–CH4) via PCB jumpers.

- Signal Types (selectable per channel):

• Current input: 4–20mA DC (for pressure/flow sensors), input impedance ≤ 250Ω, accuracy ±0.1% of full scale (FS);

• Voltage input: 0–10V DC (for position sensors), input impedance ≥ 100kΩ, accuracy ±0.2% FS;

• RTD input: 3-wire Pt100 (for temperature), measurement range -200°C to +600°C, resolution 0.1°C.

- Signal Conditioning: Each channel includes a 2nd-order RC low-pass filter (10Hz cutoff) to attenuate high-frequency noise (e.g., 50/60Hz power-line interference) by ≥40dB; dedicated 50Hz notch filter for RTD channels to eliminate power harmonics. |

| Digital I/O (DI/DO) Channels | - Quantity: 2 dual-function channels (CH5–CH6), configurable via DIP switches.

- Signal Types (selectable per channel):

• Digital Input (DI): Dry contact (NO/NC) or wet contact (24V DC), response time ≤1ms, input current ≤5mA @24V DC;

• Digital Output (DO): Single-Pole Double-Throw (SPDT) relay, contact rating 2A/250V AC or 2A/30V DC (suitable for small actuators or alarm lights).

- Protection: Each channel has a 2.5A fast-blow fuse (replaceable on PCB) for short-circuit protection; optical isolation (2500V AC, 1 minute) between digital channels and system bus to prevent ground loops. |

2. Electrical & Environmental Parameters

| Parameter Category | Specifications |

|---|

| Power Requirements | - Auxiliary Power: 24V DC ±10% (supplied by Mark VIe system auxiliary power modules, e.g., IS200PWRPG1A), power consumption ≤1.5W (no load) or ≤3W (full DO channel load).

- Protection: Reverse polarity protection (via Schottky diodes) to prevent damage from incorrect power wiring. |

| Signal Isolation | - Analog Channels: Galvanic isolation (500V AC, 1 minute) between each AI channel and system ground to suppress common-mode noise.

- Digital Channels: Optical isolation (2500V AC, 1 minute) between DI/DO channels and control system to isolate field-side EMI from core electronics.

- Isolation Resistance: ≥100MΩ @500V DC (all isolated circuits). |

| Environmental Adaptability | - Operating Temperature: -40°C to +70°C (extended range via high-temperature capacitors and terminal blocks rated for -40°C to +85°C).

- Relative Humidity: 5%–95% RH (non-condensing), with PCB conformal coating (IPC-CC-830 acrylic, 50μm thickness) to resist moisture and oil mist.

- Vibration Resistance: 5g (10–2000Hz, IEC 60068-2-6) for sinusoidal vibration; 10g shock (11ms half-sine, IEC 60068-2-27).

- EMC Compliance: EN 61000-6-2 (industrial immunity) – withstands 10V/m RF interference (80MHz–1GHz) and 4kV contact ESD. |

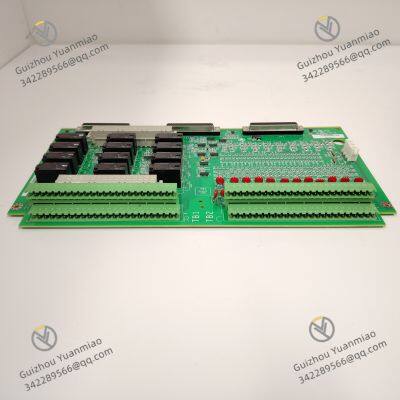

| Physical Dimensions | - Size (L × W × H): 180mm × 120mm × 30mm (fits standard 19-inch Mark VIe I/O racks, 1U height).

- Terminal Blocks: Phoenix-style pluggable terminal blocks (3.81mm pitch), tool-less clamping (accepts 0.5–2.5mm² stranded wire).

- Weight: ~0.3kg (including terminal blocks and mounting hardware). |

III. Core Functions & Technical Features1. Signal Conditioning & Noise Suppression

Industrial environments generate significant electrical noise (e.g., from variable-frequency drives, high-voltage cables), which can distort sensor signals. The IS200TDBTH6ACD mitigates this via targeted hardware design:

Low-Pass & Notch Filtering: Analog channels use 2nd-order RC low-pass filters (10Hz cutoff) to block high-frequency noise, while RTD channels add a 50Hz notch filter to eliminate power-line harmonics—critical for temperature measurements, where even small noise can cause ≥1°C reading errors.

Surge & ESD Protection: Every I/O channel integrates TVS (Transient Voltage Suppression) diodes (50V for analog, 36V for digital) that clamp voltage spikes (e.g., lightning-induced surges) to safe levels within 1ns. This prevents damage to expensive downstream I/O modules (e.g., IS200IBDHG1A).

2. Hardware-Based Channel Flexibility

The board supports on-site reconfiguration without software programming, adapting to diverse field device requirements:

Analog Channel Jumpers: Jumper blocks (J1–J4) on the PCB let users switch each AI channel between 4–20mA, 0–10V, or Pt100 RTD inputs. For example, setting J1 to "CURR" configures CH1 for 4–20mA pressure sensors, while "RTD" adapts it for Pt100 temperature probes.

Digital Channel DIP Switches: A 2-position DIP switch (SW1) sets CH5–CH6 to DI or DO mode. SW1-1 = "ON" configures CH5 as a DO relay output; SW1-1 = "OFF" sets it to a DI input. This eliminates the need for separate DI/DO terminal boards, reducing inventory and installation costs.

3. Maintenance-Focused Design

The board minimizes downtime with features that simplify troubleshooting and replacement:

Front-Panel Status LEDs: 6 LED indicators (1 per channel) provide at-a-glance status:

Analog channels (CH1–CH4): Green = signal within 0–110% FS; Red = signal out of range or open circuit.

Digital channels (CH5–CH6): Green = DI active/DO relay energized; Yellow = DO relay fault (e.g., contact sticking).

Pluggable Terminal Blocks: Terminal blocks are detachable (Phoenix-style), allowing technicians to disconnect the board from field wiring without removing individual wires. This cuts module replacement time from ~30 minutes (for soldered terminals) to <5 minutes.

Remote Fault Reporting: The board communicates fault status (e.g., open AI channel, DO short circuit) to the Mark VIe controller via the system bus. Fault codes (e.g., "E03-AI CH2 Open") are visible in GE’s ToolboxST software, enabling remote diagnostics without on-site visits.

4. Rugged Industrial Construction

To withstand harsh operating conditions, the board incorporates durability-focused features:

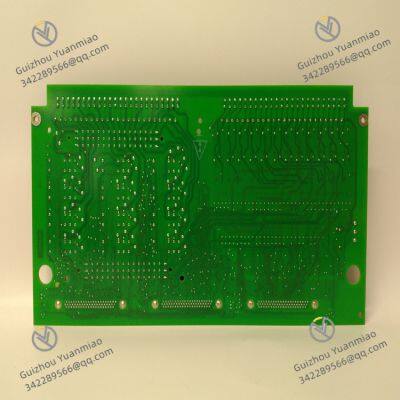

Conformal Coating: The PCB is coated with a 50μm acrylic layer (IPC-CC-830) that resists moisture, dust, and chemical exposure (e.g., oil mist in turbine enclosures), preventing solder joint corrosion and short circuits.

High-Temperature Components: Passive components (capacitors, resistors) and terminal blocks use materials rated for -40°C to +70°C, ensuring stable performance in unconditioned cabinets (e.g., offshore platforms, desert power plants).

Vibration-Resistant Mounting: The board uses M3 threaded standoffs with lock washers for rack mounting, preventing loosening under 5g vibration (common in turbine halls or compressor stations).

IV. Compatible Systems & Maintenance Guidelines1. Compatible Hardware & Software

The IS200TDBTH6ACD requires specific GE Mark VIe/VI components to function; it cannot be used with non-GE systems:

Core I/O Modules: Must pair with Mark VIe/VI analog/digital I/O modules:

Power Supply: GE IS200PWRPG1A (24V DC, 5A) or IS200PWRPG2A (redundant 24V DC) auxiliary power module.

Configuration Software: GE ToolboxST (version ≥ V9.0) for monitoring channel status, reading fault codes, and verifying signal integrity (no programming required—only for diagnostics).

2. Installation Guidelines

Wiring Best Practices:

Use shielded twisted-pair (STP) cable for analog signals (e.g., 22AWG STP for 4–20mA) to minimize EMI. Ground the shield at the terminal board (single-point grounding) to avoid ground loops.

For digital DI signals, use 18–22AWG stranded wire (max length 100m for dry contacts, 50m for wet contacts) to prevent voltage drop.

Mounting Requirements: Install in the Mark VIe/VI I/O rack’s "terminal layer" (above core I/O modules) for easy access to wiring. Maintain ≥10mm clearance between adjacent boards for airflow and heat dissipation.

Power Polarity Check: Verify 24V DC power wiring (terminal 1 = "+," terminal 2 = "-") before energizing. Reverse polarity triggers the built-in diode protection but may disable the board until corrected.

3. Routine Maintenance

Monthly Inspections: Check front-panel LEDs for abnormal status (e.g., red AI LEDs without open circuits) and tighten terminal blocks (torque 0.5–0.8N·m) to prevent loose connections.

Quarterly Cleaning: Use a soft brush to remove dust from the board and terminal blocks (avoid compressed air, which may damage the conformal coating). Inspect terminals for corrosion (common in humid environments) and clean with isopropyl alcohol if needed.

Annual Calibration: For critical analog channels (e.g., turbine bearing temperature), use a standard signal generator (e.g., Fluke 726) to inject known signals (4mA, 20mA for current inputs) and verify accuracy via ToolboxST. Adjust the paired I/O module’s calibration offset if deviation exceeds ±0.1% FS.

4. Troubleshooting Reference

| Symptom | Possible Cause | Resolution |

|---|

| AI channel LED is red (out of range) | 1. Field sensor failure (e.g., broken Pt100); 2. Open signal cable; 3. Incorrect jumper setting. | 1. Test sensor with a multimeter (e.g., check Pt100 resistance); 2. Verify cable continuity; 3. Adjust jumper to match sensor type. |

| DO channel LED is yellow (fault) | 1. Short circuit in load (e.g., solenoid valve); 2. Blown 2.5A fuse; 3. Relay contact sticking. | 1. Disconnect load and test for shorts; 2. Replace fuse (F1/F2 on PCB); 3. Replace the terminal board if the relay is faulty. |

| All LEDs off (no power) | 1. Power module failure; 2. Reverse polarity; 3. Loose power terminal. | 1. Check IS200PWRPG1A output (22.8–26.4V DC); 2. Correct power wiring; 3. Tighten power terminals (1–2). |

III. Core Functions & Technical Features1. Signal Conditioning & Noise Suppression

III. Core Functions & Technical Features1. Signal Conditioning & Noise Suppression IV. Compatible Systems & Maintenance Guidelines1. Compatible Hardware & Software

IV. Compatible Systems & Maintenance Guidelines1. Compatible Hardware & Software