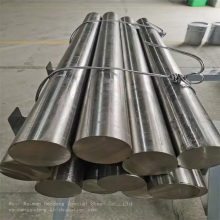

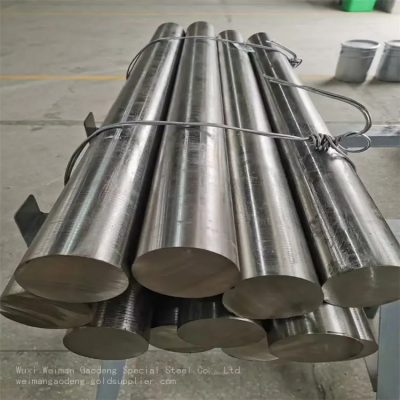

Nichrome Round Circle Rod Inconel 713 718 Pure Nickel Round Bar UNS N07713 713C Alloy Bar

Our Nichrome Round Circle Rod, specifically the Inconel 713 and 718 variants, along with the Pure Nickel Round Bar and UNS N07713 713C Alloy Bar, represents a pinnacle of engineering and metallurgical excellence. These rods are crafted with precision to meet the most demanding industrial applications across the globe.

Material CompositionInconel 713 and 718: These are nickel - based superalloys that offer a unique combination of high - temperature strength, oxidation resistance, and corrosion resistance. Inconel 713 contains significant amounts of chromium, molybdenum, and other alloying elements, which contribute to its excellent mechanical properties at elevated temperatures. Inconel 718, on the other hand, has a high nickel content along with chromium, iron, and niobium, providing outstanding strength and toughness.

Pure Nickel Round Bar: As the name suggests, it is made of nearly pure nickel. Nickel is known for its good electrical and thermal conductivity, as well as its resistance to corrosion in many chemical environments.

UNS N07713 713C Alloy Bar: This alloy is a specialized form of the Inconel 713 series. It has a carefully balanced composition that enhances its performance in extreme conditions, such as high - stress and high - temperature applications.

The rods undergo a meticulous polishing process as a surface treatment. This not only gives them an aesthetically pleasing silver color but also offers several functional benefits.

Enhanced Corrosion Resistance: A polished surface reduces the number of surface irregularities where corrosion can initiate. It forms a smooth barrier that is more resistant to the penetration of corrosive agents, ensuring a longer service life for the rods.

Improved Cleanability: The smooth surface is easier to clean, making it suitable for applications where hygiene is crucial, such as in the food and beverage or pharmaceutical industries.

Better Lubrication: In applications involving moving parts, the polished surface allows for better lubrication, reducing friction and wear.

One of the key advantages of our products is the ability to customize the shape according to the customer's blueprint.

Precision Manufacturing: Our state - of - the - art manufacturing facilities are equipped with advanced machinery that can produce rods with extremely high precision. Whether it's a simple round rod with specific dimensions or a complex shape with intricate details, we can meet the exact requirements of our customers.

Flexibility for Diverse Applications: This customization option makes our rods suitable for a wide range of industries, including aerospace, automotive, energy, and more. For example, in the aerospace industry, custom - shaped rods can be used in engine components, while in the automotive industry, they can be used in high - performance braking systems.

High - Temperature Resistance: The Inconel 713, 718, and UNS N07713 713C alloys are designed to maintain their strength and integrity at high temperatures. They can withstand temperatures up to several hundred degrees Celsius without significant loss of mechanical properties. This makes them ideal for use in gas turbines, jet engines, and other high - temperature applications.

Corrosion Resistance: All our rods, including the pure nickel round bar, offer excellent corrosion resistance in various environments. They can resist corrosion in acidic, alkaline, and salt - water environments, making them suitable for marine applications, chemical processing plants, and oil and gas industries.

Mechanical Strength: These rods have high tensile strength and yield strength, allowing them to withstand heavy loads and stresses. They can be used in structural applications where reliability and durability are of utmost importance.

We are a manufacturer with a strong commitment to quality. Since our establishment in 2017, we have built a reputation for producing high - quality products.

Strict Quality Control: Our products undergo multiple stages of quality control during the manufacturing process. From raw material inspection to final product testing, we ensure that every rod meets the highest standards of quality.

International Market Presence: With an export share of US$5 Million - US$10 Million, we have a wide - reaching market presence that includes North America, South America, Europe, Asia, Africa, and Oceania. Our products are trusted by customers in diverse industries around the world.

Aerospace Industry: Used in engine components, turbine blades, and structural parts due to their high - temperature strength and corrosion resistance.

Automotive Industry: Employed in high - performance braking systems, engine components, and exhaust systems.

Energy Sector: Ideal for use in power generation plants, especially in gas turbines and nuclear reactors, because of their ability to withstand extreme conditions.

Chemical and Petrochemical Industries: Suitable for equipment such as pipes, valves, and heat exchangers due to their corrosion resistance.

Our Nichrome Round Circle Rods, including Inconel 713, 718, Pure Nickel Round Bar, and UNS N07713 713C Alloy Bar, offer a combination of high - performance materials, excellent surface treatment, customizable shapes, and reliable quality, making them the top choice for a wide range of international customers.

Send Inquiry to This Supplier

You May Also Like

-

Nickel 201 Alloy (UNS N02201) /2.4068 Bright Nickel Alloy Steel Round BarNegotiableMOQ: 1 Ton

-

Uns N02201 Nickel Bar High Purity Nickel200 Pure Nickel Rod N02200 Nickel Alloy Round BarNegotiableMOQ: 1 Ton

-

Custom Uns N02201Super Alloy Rod for Electronic Components Purity Nickel 201 Alloy BarNegotiableMOQ: 1 Ton

-

Manufacturer of Nickel 200/N02200 Bright Round Nickel Rod/Bar for Industrial Forged/Forging Round Bars NickelNegotiableMOQ: 1 Ton

-

Nickel 201/N02201 Custom Size Nickel Based Alloy Nickel Rod BarNegotiableMOQ: 1 Ton

-

Incoloy Alloy Bar Incoloy 925, N09925, Incoloy 800 for High-Temperature and Corrosion-Resistant ApplicationsNegotiableMOQ: 1 Ton

-

High-Strength Incoloy Alloy Bar Incoloy 330, N08330, RA330 for Industrial Heat TreatmentNegotiableMOQ: 1 Ton

-

Incoloy 800H Alloy Bar N08810, Incoloy 800HT for High-Temperature and Oxidation ResistanceNegotiableMOQ: 1 Ton

-

Incoloy 825 Bar N08825, Incoloy926, N08926 for Corrosive Environments in Chemical ProcessingNegotiableMOQ: 1 Ton

-

Incoloy Alloy Bar Incoloy 901, IncoloyA-286, S66286 for High-Stress and Aerospace ApplicationsNegotiableMOQ: 1 Ton