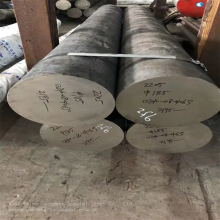

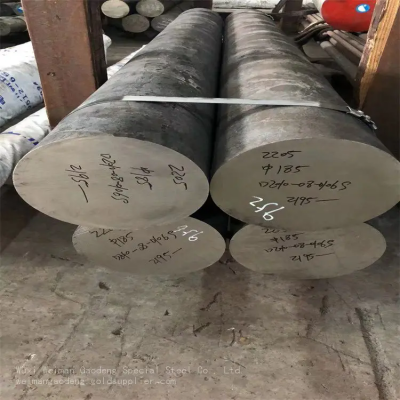

Factory Price Alloy Steel Round Bar Inconel751,Inconel939

Welcome to explore our high - quality alloy steel round bars, specifically Inconel 751 and Inconel 939. These products are crafted by Wuxi Weiman Gaodeng Special Steel Co., Ltd., a reputable manufacturer established in 2017. With an annual export volume ranging from US$5 Million - US$10 Million, our products have gained a solid foothold in various global markets including North America, South America, Europe, Asia, Africa, and Oceania.

Type: Our alloy steel round bars belong to the nickel - based precision alloy category. Nickel - based alloys are renowned for their excellent performance under extreme conditions, making them ideal for a wide range of industrial applications.

Surface Treatment: The round bars undergo a meticulous polishing process. This surface treatment not only gives the bars a smooth and shiny silver appearance but also enhances their corrosion resistance. A polished surface reduces the chances of surface defects and makes the bars more resistant to environmental factors such as moisture and chemical exposure.

Shape: We understand that different customers may have different requirements. Therefore, we offer the option to customize the shape of the round bars according to your provided blueprint. Whether it's a simple cylindrical shape or a more complex design, our experienced team can manufacture the bars to meet your exact specifications.

High - Temperature Resistance: Inconel 751 is well - known for its outstanding high - temperature performance. It can maintain its mechanical properties even at elevated temperatures, making it suitable for applications in high - temperature environments such as aerospace engines and gas turbines.

Strength and Toughness: This alloy has excellent strength and toughness, which allows it to withstand heavy loads and mechanical stresses. It can resist deformation and cracking under harsh operating conditions, ensuring long - term reliability in critical applications.

Corrosion Resistance: Inconel 751 offers good corrosion resistance in a variety of corrosive media, including acids, alkalis, and salts. This property makes it a popular choice for applications in chemical processing plants, marine environments, and other corrosive settings.

Oxidation Resistance: Inconel 939 has superior oxidation resistance, especially at high temperatures. A stable oxide layer forms on its surface, which acts as a protective barrier against further oxidation and degradation. This makes it an excellent choice for components exposed to high - temperature oxidizing atmospheres.

Creep Resistance: Creep is the slow deformation of a material under a constant load at high temperatures. Inconel 939 exhibits excellent creep resistance, which means it can maintain its shape and integrity over long periods of time in high - temperature and high - stress applications.

Weldability: Another advantage of Inconel 939 is its good weldability. It can be easily welded using common welding techniques, allowing for the fabrication of complex structures and components.

Aerospace Industry: Both Inconel 751 and Inconel 939 are widely used in the aerospace industry. They are used to manufacture engine components, such as turbine blades, discs, and combustion chambers, where high - temperature resistance, strength, and corrosion resistance are crucial.

Power Generation: In power plants, these alloy steel round bars are used in gas turbines and steam turbines. Their high - temperature and creep resistance properties ensure the efficient and reliable operation of power generation equipment.

Chemical Processing: The corrosion resistance of Inconel 751 and Inconel 939 makes them suitable for use in chemical processing plants. They can be used to manufacture pipes, valves, and other equipment that come into contact with corrosive chemicals.

We are committed to providing high - quality products. Our manufacturing process adheres to strict quality control standards. Each batch of alloy steel round bars is thoroughly inspected for dimensions, surface quality, and mechanical properties. We use advanced testing equipment and techniques to ensure that our products meet or exceed international quality standards.

Our team of 11 - 20 experienced sales representatives is dedicated to providing excellent customer service. Whether you have questions about the product, need a quote, or want to discuss customization options, our manager, Sang Le, and the rest of the team are ready to assist you. You can reach us via WhatsApp at +8615995395119 or visit our factory at No. 168 Qiangao Road.

Choose our factory - price alloy steel round bars Inconel 751 and Inconel 939 for your next project, and experience the superior quality and performance that our products offer.

Send Inquiry to This Supplier

You May Also Like

-

Uns N02201 Nickel Bar High Purity Nickel200 Pure Nickel Rod N02200 Nickel Alloy Round BarNegotiableMOQ: 1 Ton

-

Custom Uns N02201Super Alloy Rod for Electronic Components Purity Nickel 201 Alloy BarNegotiableMOQ: 1 Ton

-

Manufacturer of Nickel 200/N02200 Bright Round Nickel Rod/Bar for Industrial Forged/Forging Round Bars NickelNegotiableMOQ: 1 Ton

-

Nickel 201/N02201 Custom Size Nickel Based Alloy Nickel Rod BarNegotiableMOQ: 1 Ton

-

Incoloy Alloy Bar Incoloy 925, N09925, Incoloy 800 for High-Temperature and Corrosion-Resistant ApplicationsNegotiableMOQ: 1 Ton

-

High-Strength Incoloy Alloy Bar Incoloy 330, N08330, RA330 for Industrial Heat TreatmentNegotiableMOQ: 1 Ton

-

Incoloy 800H Alloy Bar N08810, Incoloy 800HT for High-Temperature and Oxidation ResistanceNegotiableMOQ: 1 Ton

-

Incoloy 825 Bar N08825, Incoloy926, N08926 for Corrosive Environments in Chemical ProcessingNegotiableMOQ: 1 Ton

-

Incoloy Alloy Bar Incoloy 901, IncoloyA-286, S66286 for High-Stress and Aerospace ApplicationsNegotiableMOQ: 1 Ton

-

Incoloy 926 Bar N08926, Incoloy 800H for Marine and Chemical Industries With Superior Corrosion ResistanceNegotiableMOQ: 1 Ton