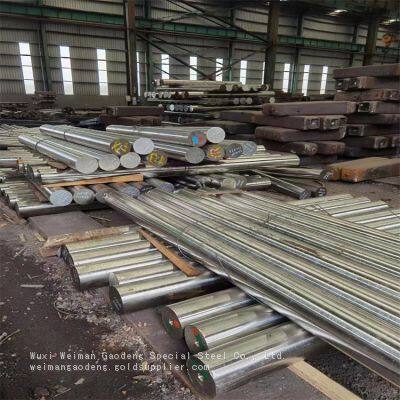

Nickel 201 Alloy (UNS N02201) /2.4068 Bright Nickel Alloy Steel Round Bar

The Nickel 201 Alloy (UNS N02201) / 2.4068 Bright Nickel Alloy Steel Round Bar is a high - quality product designed to meet the diverse needs of various industries. This round bar is part of the nickel - based precision alloy category, offering exceptional performance and reliability.

Chemical CompositionThis alloy is primarily composed of nickel, with a high purity level. The low carbon content in Nickel 201 (UNS N02201) makes it suitable for applications where resistance to corrosion in high - temperature environments is crucial. In addition to nickel, it may contain small amounts of other elements such as iron, manganese, carbon, silicon, and sulfur. These elements are carefully balanced to enhance the overall properties of the alloy, including its mechanical strength and chemical stability.

The surface of the round bar undergoes a polishing treatment. This not only gives it a smooth and shiny silver appearance but also offers several practical advantages. The polished surface reduces friction, which can be beneficial in applications where the bar will be in contact with other components. It also provides an additional layer of protection against corrosion, as it is less likely to accumulate dirt, moisture, or other contaminants compared to a rough surface.

One of the key features of this product is its ability to be customized according to the blueprint provided by the customer. Whether you need a specific diameter, length, or any other geometric specification, our manufacturing process can accommodate your requirements. This flexibility makes it an ideal choice for a wide range of industries, including aerospace, automotive, and chemical processing. For example, in the aerospace industry, where precision is of utmost importance, customized round bars can be used in the construction of engine components or structural parts.

Physical and Mechanical PropertiesDensity: The density of the Nickel 201 Alloy round bar is relatively high, which is typical of nickel - based alloys. This high density contributes to its strength and durability.

Tensile Strength: It exhibits excellent tensile strength, allowing it to withstand significant pulling forces without breaking. This property makes it suitable for applications where the bar will be subjected to heavy loads, such as in the construction of bridges or large - scale machinery.

Corrosion Resistance: The nickel - based composition gives the round bar outstanding corrosion resistance. It can resist corrosion in various environments, including acidic, alkaline, and marine conditions. This makes it a reliable choice for applications in the chemical and offshore industries.

Chemical Processing: In the chemical industry, the round bar can be used in the construction of reactors, pipes, and valves. Its corrosion resistance ensures long - term performance in harsh chemical environments.

Electronics: Due to its electrical conductivity and corrosion resistance, it can be used in the manufacturing of electronic components, such as connectors and circuit boards.

Food Processing: The smooth and corrosion - resistant surface makes it suitable for use in food processing equipment, where hygiene and durability are essential.

As a manufacturer established in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is committed to providing high - quality products. With an export share ranging from US$5 Million - US$10 Million and a team of 11 - 20 experienced salespeople, we have the resources and expertise to ensure that each round bar meets the highest quality standards. Our products are sold in major markets around the world, including North America, South America, Europe, Asia, Africa, and Oceania.

Packaging and ShippingWe take great care in packaging the Nickel 201 Alloy round bars to ensure they arrive at your location in perfect condition. They are typically packed in protective materials to prevent damage during transportation. We also offer various shipping options to meet your delivery requirements, whether you need express shipping for urgent orders or standard shipping for more cost - effective solutions.

Send Inquiry to This Supplier

You May Also Like

-

High-Strength Incoloy Alloy Bar Incoloy 330, N08330, RA330 for Industrial Heat TreatmentNegotiableMOQ: 1 Ton

-

Incoloy 800H Alloy Bar N08810, Incoloy 800HT for High-Temperature and Oxidation ResistanceNegotiableMOQ: 1 Ton

-

Incoloy 825 Bar N08825, Incoloy926, N08926 for Corrosive Environments in Chemical ProcessingNegotiableMOQ: 1 Ton

-

Incoloy Alloy Bar Incoloy 901, IncoloyA-286, S66286 for High-Stress and Aerospace ApplicationsNegotiableMOQ: 1 Ton

-

Incoloy 926 Bar N08926, Incoloy 800H for Marine and Chemical Industries With Superior Corrosion ResistanceNegotiableMOQ: 1 Ton

-

Incoloy 945X, Incoloy 945, Incoloy 925 for Power Plant Equipment and Heavy-Duty ApplicationsNegotiableMOQ: 1 Ton

-

Incoloy 800 Alloy Bar N08810, Incoloy 800HT for High-Temperature Furnace and Reactor ApplicationsNegotiableMOQ: 1 Ton

-

Incoloy 803, Incoloy 907, Incoloy 909 Alloy Bar for Heat-Resistant Components in Gas TurbinesNegotiableMOQ: 1 Ton

-

Incoloy 020, Incoloy 27-7MO, Incoloy 926 for Harsh Chemical and Marine EnvironmentsNegotiableMOQ: 1 Ton

-

Versatile Size Ranges of Inconel Alloy Bar Including Inconel 706 and Inconel 740H for Industrial UseNegotiableMOQ: 10 Kilograms