ASTM A333 Gr.6 grade 6 low temperature seamless steel pipe

Low-temperature seamless steel pipes are industrial pipes manufactured through two main production processes: cold drawing and hot rolling, specifically designed for low-temperature working conditions. Its manufacturing standards need to meet the mechanical property requirements under specific low-temperature conditions and are applicable to fields such as liquefied natural gas transportation and cryogenic storage tanks

Name:Low-temperature seamless steel pipe

Standard:ASTM A333

Impact temperature:- 45 ℃ -- 195 ℃

Yield strength:≥205MPa

Tensile strength:≥380MPa

ASTM A333--Seamless Steel Pipe for Low-Temperature Service

Mechanical Properties | |||||||||||||||||||||

Standard | Steel Grade | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | |||||||||||||||||

Longitudinal | Horizontal | ||||||||||||||||||||

ASTM A333 | Grade 1 | ≥380 | ≥205 | ≥35 | ≥25 | ||||||||||||||||

Grade 3 | ≥450 | ≥240 | ≥30 | ≥20 | |||||||||||||||||

Grade 4 | ≥415 | ≥240 | ≥30 | ≥16.5 | |||||||||||||||||

Grade 6 | ≥415 | ≥240 | ≥30 | ≥16.5 | |||||||||||||||||

Grade 7 | ≥450 | ≥240 | ≥30 | ≥22 | |||||||||||||||||

Grade 8 | ≥690 | ≥515 | ≥22 | ||||||||||||||||||

Grade 9 | ≥435 | ≥315 | ≥28 | ||||||||||||||||||

Grade 10 | ≥550 | ≥450 | ≥22 | ||||||||||||||||||

Grade 11 | ≥450 | ≥240 | ≥18 | ||||||||||||||||||

Impact temperature | |||||||||||||||||||||

Steel grade | Minimum impact test temperature | ||||||||||||||||||||

F | ℃ | ||||||||||||||||||||

Grade 1 | -50 | -45 | |||||||||||||||||||

Grade 3 | -150 | -100 | |||||||||||||||||||

Grade 4 | -150 | -100 | |||||||||||||||||||

Grade 6 | -50 | -45 | |||||||||||||||||||

Grade 7 | -100 | -75 | |||||||||||||||||||

Grade 8 | -320 | -195 | |||||||||||||||||||

Grade 9 | -100 | -75 | |||||||||||||||||||

Grade 10 | -75 | -60 | |||||||||||||||||||

Chemical Composition | |||||||||||||||||||||

Standard | Steel grade | Chemical composition(%) | |||||||||||||||||||

C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V | Al | |||||||||||

ASTM | Grade 1 | ≤0.30 | 0.40-1.06 | ≤0.025 | ≤D.025 | ||||||||||||||||

Grade 3 | ≤0.19 | 0.18-0.37 | 0.31-0.64 | ≤0.025 | ≤D.025 | 3.18-3.82 | |||||||||||||||

Grade 4 | ≤0.12 | 0.18-0.37 | 0.50-1.05 | ≤0.025 | ≤D.025 | 0.44-1.01 | 0.47-0.98 | 0.40-0.75 | 0.04-0.30 | ||||||||||||

Grade 6 | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.025 | ≤D.025 | ||||||||||||||||

Grade 7 | ≤0.19 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤D.025 | 2.03-2.57 | |||||||||||||||

Grade 8 | ≤0.13 | 0.13-0.32 | ≤D.90 | ≤0.025 | ≤0.025 | 8.40-9.60 | |||||||||||||||

Grade 9 | ≤0.20 | 0.40-1.06 | ≤0.025 | ≤0.025 | 1.60-2.24 | 0.75-1.25 | |||||||||||||||

Grade 10 | ≤0.20 | 0.10-0.35 | 1.15-1.50 | ≤0.03 | ≤0.015 | ≤0.15 | ≤0.25 | ≤0.015 | ≤0.50 | ≤0.12 | ≤0.06 | ||||||||||

Grade 11 | ≤0.10 | ≤0.35 | ≤0.6 | ≤0.025 | ≤D.025 | ≤0.50 | 35.0-37.0 | ≤0.50 | |||||||||||||

Production process:

The main production processes of low-temperature steel pipes include cold drawing and hot rolling.

Application field:

This pipe material is mainly applied in low-temperature industrial scenarios such as liquefied natural gas (LNG) transportation pipelines, liquid nitrogen storage and transportation equipment, and ethylene cracking units. In the liquefied natural gas receiving station, it needs to withstand a low-temperature medium of -162℃, and the pipe material is required to have the ability to resist low-temperature brittle fracture.

Technical characteristics:

The alloying element ratio of seamless steel pipes for low-temperature use needs to be optimized, with the content of carbon and manganese, and at the same time, nickel, molybdenum and other elements should be added to enhance low-temperature stability. Before leaving the factory, the pipes need to undergo tensile tests at a low temperature of -100℃ to ensure that the yield strength and elongation meet the standard requirements.

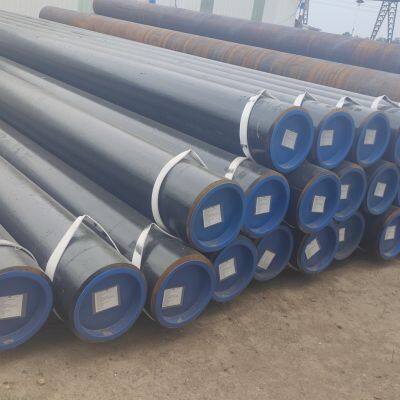

The wall thickness tolerance control is stricter than that of conventional seamless steel pipes. The tolerance of cold-drawn process products can reach ±5%, while that of hot-rolled process products is usually controlled within ±10%. The inner surface needs to be shot peened to reduce the resistance of medium flow, and the outer surface is coated with epoxy powder to enhance corrosion resistance.

Quality control:

The manufacturer needs to establish a low-temperature impact test laboratory and conduct drop weight tear tests (DWTT) by sampling batches. For pipes with a thickness exceeding 20mm, Z-direction performance tests should be added to prevent layered tearing.

Finished pipes must undergo ultrasonic flaw detection one by one, and the echo amplitude of defects must not exceed the value specified in the standard. The pipe ends need to be beveled and protective measures should be implemented to ensure the fusion quality during on-site welding.

Send Inquiry to This Supplier

You May Also Like

-

34CrMo4 37Mn Gas Cylinder TubeNegotiableMOQ: 30 Metric Tons

-

Baotou Steel NACE MR0175 ISO15156 Sour Service X52 PSL2 X60QS Seamless Steel PipeNegotiableMOQ: 30 Metric Tons

-

Baotou Steel GB/T9948 10# 20# 15CrMo Petroleum Cracking Steel PipesNegotiableMOQ: 30 Metric Tons

-

Baotou Steel GB/T6479 20# Q345B Q345C Q345D Q345E High Pressure Fertilizer Steel PipeNegotiableMOQ: 30 Metric Tons

-

Baotou Steel GB/T17396 30CrMnSiA 27SiMn Hydraulic Prop Steel PipeNegotiableMOQ: 30 Metric Tons

-

Baotou Steel GB/T9808 DZ50 R780 DZ40 Geological Steel PipeNegotiableMOQ: 30 Metric Tons

-

Baotou Steel API 5L Seamless Steel PipeNegotiableMOQ: 30 Metric Tons

-

Baotou Steel HG20553 (Ia) GB/T9948 15CrMo 10# 20# Seamless Steel Pipes for Chemical IndustryNegotiableMOQ: 30 Metric Tons

-

Baotou Steel Seamless PipesNegotiableMOQ: 30 Metric Tons

-

Baotou Steel Sour Service X60 X52 Seamless PipesNegotiableMOQ: 30 Metric Tons