High Strength Commercially Pure Titanium Round Bar Industrial Grade Titanium Alloy

High Strength Commercially Pure Titanium Round Bar: Industrial Grade Titanium Alloy

Introduction

In the realm of industrial materials, the high - strength commercially pure titanium round bar stands out as a remarkable product. This titanium alloy is a result of advanced manufacturing techniques and high - quality raw materials, offering a wide range of benefits for various industrial applications.

Product Specifications

Shape

The bar comes in a round shape, which is a classic and highly versatile form. The round shape allows for easy machining, welding, and integration into different industrial setups. It can be used as a core component in machinery, as a structural element in construction projects, or as a part in precision instruments.

Grade

Available in multiple grades including Gr1, Gr2, Gr16, Gr7, Gr12, and Gr5. Each grade has its unique set of properties. For instance, Grade 1 is known for its excellent formability and corrosion resistance, making it suitable for applications where the material needs to be shaped without sacrificing its integrity. Grade 5, on the other hand, is a high - strength alloy that combines good ductility with enhanced mechanical properties, often used in aerospace and high - stress industrial applications.

Technique

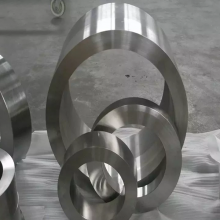

These titanium bars are forged. Forging is a manufacturing process that involves shaping metal using compressive forces. This technique enhances the internal structure of the titanium, resulting in a bar with superior strength, toughness, and resistance to fatigue. The forging process also allows for better control over the grain structure of the metal, which in turn improves its overall performance in industrial environments.

Industrial Applications

Aerospace

In the aerospace industry, the high - strength and lightweight nature of these titanium round bars make them ideal for use in aircraft components. They can be used in engine parts, landing gear, and structural frames. The corrosion resistance of titanium ensures that these components can withstand the harsh conditions of high - altitude flight, including exposure to moisture, chemicals, and extreme temperatures.

Chemical Processing

Titanium's excellent corrosion resistance makes it a top choice for the chemical processing industry. These round bars can be used in the construction of reaction vessels, pipelines, and heat exchangers. They can resist the corrosive effects of acids, alkalis, and other chemicals, ensuring the long - term stability and safety of chemical processing plants.

Medical

In the medical field, commercially pure titanium is biocompatible, which means it can be safely used in contact with the human body. The round bars can be used to manufacture medical implants such as bone plates, screws, and dental implants. Their strength and durability ensure that these implants can support the body's functions over an extended period.

Material Advantages

High Strength - to - Weight Ratio

One of the most significant advantages of this titanium alloy is its high strength - to - weight ratio. Compared to traditional metals like steel, titanium offers similar or even higher strength while being much lighter. This property is crucial in industries where weight reduction is essential, such as aerospace and automotive. It allows for the design of more fuel - efficient vehicles and aircraft, reducing energy consumption and environmental impact.

Corrosion Resistance

Titanium has a natural oxide layer on its surface that provides excellent protection against corrosion. This means that the round bars can be used in harsh environments without the need for additional protective coatings. Whether it's in a marine environment, a chemical plant, or an outdoor structure, the titanium bars will maintain their integrity over time, reducing maintenance costs and increasing the lifespan of the products.

Manufacturer Information

The high - strength commercially pure titanium round bars are manufactured by a reputable company. Established in 2017, this manufacturer has a team of 11 - 20 experienced salespersons. With an export share ranging from US$5 Million - US$10 Million, the company has a strong presence in multiple markets around the world, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as the domestic market. The company's commitment to quality and innovation ensures that customers receive products that meet the highest industry standards.

Send Inquiry to This Supplier

You May Also Like

-

Factory High-Accuracy Polish Gr1 Gr2 Gr5 Gr7 Gr16 Gr12 Round Titanium Bar Titanium Alloy Bar Titanium RodsNegotiableMOQ: 1 Ton

-

Hot/Cold Rolled 4X8 Gr1 Gr2 Gr5 Titanium Alloy Plate Sheet Metal Price Per KgNegotiableMOQ: 1 Ton

-

Titanium Alloy Sheet Gr1, Gr2, Gr5 (Ti-6Al-4V) , Gr7,, Gr12 (Ti-0.3-Mo-0.8Ni) and Titanium PlateNegotiableMOQ: 1 Ton

-

Round Grade 5 Titanium Bar Rod,ti-6al-4v Titanium Alloy Rod,titanium Rod Gr 5NegotiableMOQ: 1 Ton

-

High Purity Gr5 Titanium Ti-13nb-13zr Alloy Rounded Bar for MedicalNegotiableMOQ: 1 Ton

-

China Manufacturers High Quality Astm Gr2 Gr1 Gr5 Gr7 Gr12 Gr16 Titanium Bar / RodNegotiableMOQ: 1 Ton

-

Factory Kilogram Price High-Quality Titanium Rod Titanium Rod 1 Gr 2 High-Quality Titanium RodNegotiableMOQ: 1 Ton

-

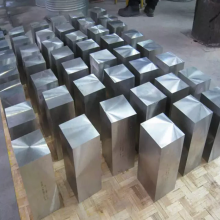

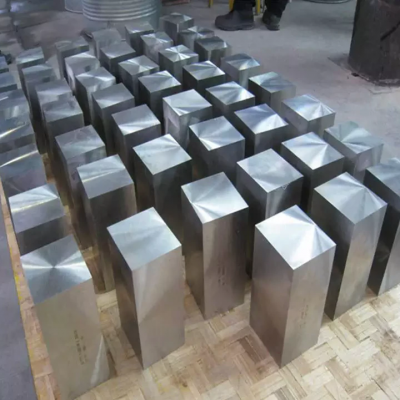

Gr2 Gr5 Industrial Pure Titanium TA1 Titanium Alloy Square Bar High Temperature Solid Square Round Titanium BarNegotiableMOQ: 1 Ton

-

Gr 1 Gr 2 Gr 5 Titanium Alloy Rod Titanium Alloy Round BarsNegotiableMOQ: 1 Ton

-

Gr7 Gr5 Gr12 Gr16 Titanium Rods Titanium Round Bar Price Per KGNegotiableMOQ: 1 Ton