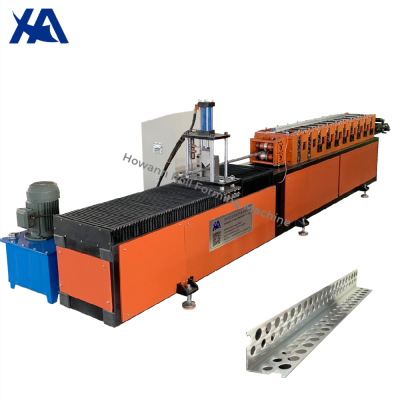

Advanced Technology Corner Bead Keel V Shape Angle Iron Light Keel Roll Forming Machine With Punching

Steel Purlin Hat/C/U/Z/L Profile Channel 120mm Size C purlin Roll Forming Machine is widely used around the world. This galvanized keel forming machine have two forming lines, but they have seperated control systems, this kind of double line light gauge keel stud track steel roll forming machine will save the space for the factory. And the products this machine produced is mainly used for the drywall and theceiling structure. As a basic material, keel steel is widely used for many aspects as assistant supporters.

1.PLC Control

You can add in-Line Printing, and PC-Controller Software allowing you to lable components and control your double line light gauge keel stud track c channel steel roll forming machine from your computer. Each option may be included with your machine or added later as your needs evolve

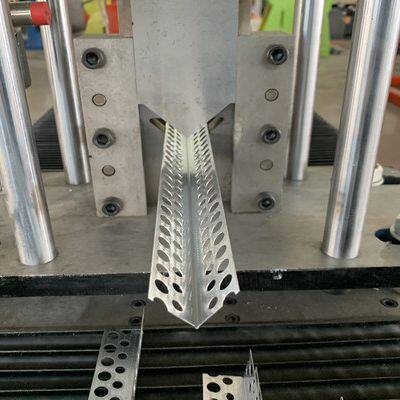

2.Holes (embossing, logo punching)

All double line light gauge keel stud track c channel steel roll forming machines can be set-up with a Service Hole, Dimple Punch, Index/Bolt Hole and Web-notch tools.

3.High speed

Servo driven punch provides close tolerance accuracy and none stop punching for increased production, with interchangeable tooling for different hole sizes and shapes.

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point. High quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machines need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q3. What’s your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name for competitive ocean freight.

Q4. What about the quality control?

A4: All raw materials we use are quality controlled.Workers will take care of every detail when handling production and packaging.

Q5. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones for free.

Q6. Is the packaging form?

A6: Yes, of course! All our machines will be packaged in dust and water proof, and they can be reinforced after loading to fully meet export packaging standards.

Q7. How long is your delivery cycle?

1) In the case of stock, we can deliver the machine within 7 days.

15-20 days.

Send Inquiry to This Supplier

You May Also Like

-

Low Cost Channel C/Z Machine Fully Automatic Cold Steel Profile C/Z Purlin Roll Forming MachineryUS$ 10000 - 12000MOQ: 1 Piece

-

High Speed Round and Square Downspout Water Gutter Pipe Bending Roll Forming MachineUS$ 19800 - 29800MOQ: 1 Piece

-

Solar Panel Strut Channel Machinery Manufacturer Unistrut C Channel Photovoltaic Support Roll Forming MachineUS$ 14000 - 16000MOQ: 1 Piece

-

Hot Sale Road Barrier Two Waves Highway Guardrail Fence Crash Production Line Rolling Forming Machinery Cold Forming MachineUS$ 25000 - 35000MOQ: 1 Piece

-

New Product Steel Pipe Making Machine Stainless Steel Pipes Making Machine Pipe Making MachineryUS$ 19800 - 26800MOQ: 1 Piece

-

High Quality Automatic Galvanized Steel Metal Floor Deck Roll Forming Machine PLC Control Used Motor Engine Tile PurlinUS$ 11000 - 12000MOQ: 1 Piece

-

Factory Processed Highway Guardrail Roll Forming Machine Road Safety Barrier Fence Roll Forming MachineUS$ 81900 - 86900MOQ: 1 Piece

-

New Photovoltaic Panel Bracket Roll Forming Machine Auto Solar Mounting System Production Line Unistrut C Channel Making MachineUS$ 21500 - 25500MOQ: 1 Piece

-

2 Layers Roofing Panel Making Machine Roof Tile Roll Forming Machine South Africa Ibr Double Layer Roll Forming MachineUS$ 7200 - 7900MOQ: 1 Piece

-

China Supplier Metal Roofing Panel Sheet Roll Forming Machine Profiling Tiles Making Machine for Building Material MachineryUS$ 4865 - 5850MOQ: 1 Piece