I. Core Parameters

1. Structural Parameters

Model | SC-AF1 | SC-AF2 | SC-AF3 |

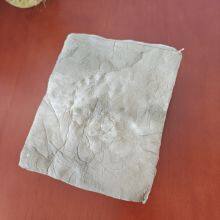

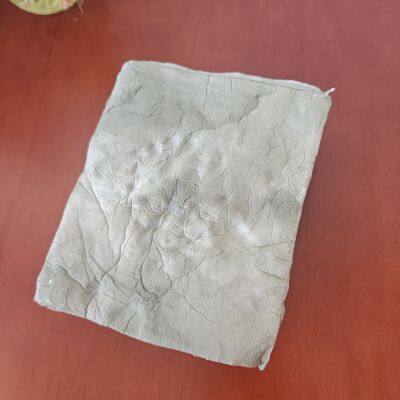

Thickness/mm | 5 | 10 | 20 |

Thermal Conductivity at Room Temperature/W·m-1·K-1 | 0.022 | 0.025 | 0.030 |

Density /g·cm-3 | 0.025 | 0.032 | 0.040 |

Compressive Strength/kPa@ 10% | 100 | 150 | 250 |

Operating Temperature/°C | >1000 | >1000 | >1000 |

Hydrophobicity Rate | >99.0% | >99.0% | >99.0% |

2. Thermal Properties

●Thermal conductivity: ≤ 0.0221 W/(m·K) at room temperature, ≤ 0.030 W/(m·K) at high temperature (400℃);

●Temperature resistance limit:

●Inert atmosphere: 1300℃ (withstand for 2 hours);

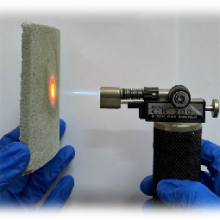

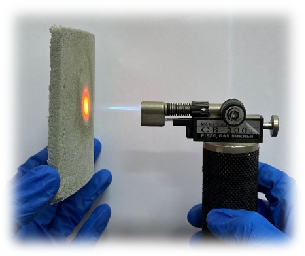

●Oxidizing atmosphere: 1600℃ (instantaneous);

●Coefficient of thermal expansion: 2.77×10-6K-1 (well matched with metal matrix).

3. Mechanical and Physical Properties

●Density: 0.025 g/cm³, adjustable according to compression ratio;

●Compressive strength: 1.365 MPa (3D printed enhanced type), Young's modulus 21.8 MPa;

●Flexibility: Bendable and foldable, tensile strength ≥ 100 kPa;

●Porosity: 90% - 99.8%, specific surface area 15 - 40 m²/g.

II. Core Features

●Lightweight and High Strength: The interpenetrating network of nanofibers endows the material with high porosity (>98%) and mechanical stability, combining low density with compressive resistance.

●Integrated Functionality: Combining the typical characteristics of aerogels (such as sound insulation and corrosion resistance) with the inherent advantages of SiC ceramics (such as oxidation resistance and thermal shock resistance).

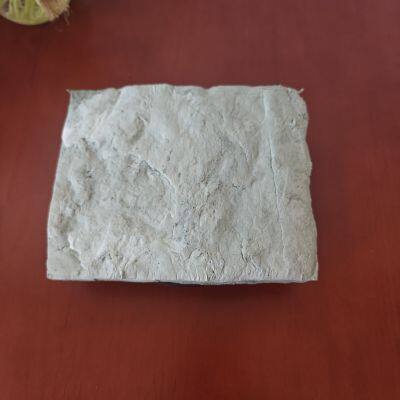

●Processability: The bulk form supports post-treatment such as cutting and coating, suitable for complex engineering scenarios.

●Multi-functionality

- Electromagnetic Wave Absorption: The one-dimensional nanowire structure optimizes radar wave absorption, suitable for military stealth coatings.

- Hydrophobic and Flame Retardant: Overall hydrophobic, with a flame retardancy rating of UL94-V0.

III. Application Fields

1. Aerospace and High-Temperature Equipment

●Spacecraft Thermal Protection: Used in the insulation layer of high-speed aircraft, it can withstand aerodynamic heating up to 1600℃.

●Aviation Engine: Turbine blade ablation-resistant coating, reducing weight by 30% and extending service life by three times.

2. New Energy and Electric Vehicles

●Battery Thermal Insulation: Insert 1-3mm aerogel felt between battery cells to prevent thermal runaway spread (withstand 400℃);

●Fuel Cell Thermal Management: Insulation layer for hydrogen fuel cell stacks to reduce cold start energy consumption.

3. Industrial Energy Conservation and Protection

●High-temperature pipelines/tanks: Replace traditional glass wool, reducing thickness by 60% (6mm aerogel blanket is equivalent to 30mm rock wool);

●Chemical reactors: Corrosion-resistant inner lining, resistant to strong acid environments.

4. Emerging Fields

●Electronic Device Heat Dissipation: 5G base station power semiconductor packaging, thermal conductive fillers enhance heat dissipation efficiency;

●Special Clothing: Firefighter suit interlayer (≤ 450℃), delays heat transfer;

●Building Energy Conservation: Ultra-thin thermal insulation curtains (2mm thick, sound insulation 12dB).

Send Inquiry to This Supplier

You May Also Like

-

Thermal Insulation Material, Insulation Cotton, Insulation BoardUS$ 0.7 - 5MOQ: 100 Kilograms

-

EN1279 Certified Insulating Glass Units With Thermal Break SpacerUS$ 1 - 10MOQ: 1 Square Meter

-

Double Layer Vacuum Electric Thermal Insulation Can Heat the Travel Cup(Wechat:13510231336)NegotiableMOQ: 2000 Pieces

-

Eco-Friendly Rockwool Insulation Panel With Fire Rating A 600x1200mm Rock Wool Panels for Partition 40kgs DensitiUS$ 0.8MOQ: 2000 Square Meters

-

ELVAX EVA DowDuPont EVA 440 Wire Insulation Antioxidant Thermal Stability Blow Molding EVA Elastic Material Raw Material EVA 670US$ 2.53 - 2.65MOQ: 25 Kilograms

-

Alloy Steel/Hastelloy/Incoloy/Tube/Steel China Stock Ta7/Gr6 Ti6al4V Titanium Alloy PipeNegotiableMOQ: 100000 Tons

-

Quick Assembled Convenient Thermal Insulation Prefab House Casa FabricadaUS$ 900 - 1200MOQ: 18 Sets

-

DH108x1c-20fzd3 Frequency Conversion, Thermal Insulation and Moisture Compressor 1.5CNY 300 - 9800MOQ: 1 Piece

-

Insulation Material 99.5% Enameled Aluminum Conductor ChinaUS$ 3.70 - 4.00MOQ: 500 Kilograms

-

Top Sale Asa Roofing Sheet Insulation Fireproof Thermal Insulation Synthetic Resin Roofing Tile for Farm WarehouseUS$ 2.02 - 2.2MOQ: 25 Kilograms