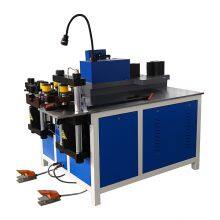

Open-Type Hydraulic Turret-Type 3 in 1 CNC Busbar Processing Machine/303A,303B,303/503C,303/503D

Open-Type CNC Busbar Processing Machine integrates three independent processing units: Punching, Cutting/Shearing, and Bending. Designed to efficiently handle copper/aluminum busbars of various specifications, all units can operate simultaneously without interference. It features simple operation, high productivity, and is widely used in switchgear and power transformer manufacturing.

Punching Unit:

Six-Station Turret Structure: Ensures absolute concentricity of upper and lower dies, extending service life and reducing long-term costs. Punching dies are made of high-strength CR12MOV steel; the center crossbeam is reinforced to 120mm.

Multi-Size Capability: Six built-in punches create six standard hole sizes, eliminating frequent die changes and significantly reducing labor intensity.

Three Positioning Modes: Pin positioning, scale positioning, and optical positioning for convenient and precise alignment.

Special Dies Compatibility: Accommodates custom dies for non-standard holes (e.g., square, oval, countersunk).

Dual Operation Modes: Foot pedal switch and push-button control.

Cutting/Shearing Unit:

Shearing-Cut Technology: Produces clean cuts with no collapse, burrs, or waste material.

Powerful Hydraulic Cylinder: Equipped with a robust 300/500KN hydraulic cylinder.

Reinforced Structure: Thickened ductile iron center crossbeam ensures superior shear guidance and prevents cylinder loosening.

Dual Operation Modes: Foot pedal switch and push-button control.

Bending Unit:

Dual-Level Worktable: Enables efficient workflow.

Precision Control: Siemens PLC control system ensures high bending accuracy.

Versatile Forming: Interchangeable dies handle flat bends, vertical bends, U-bends, embossing, flattening, twisting, and pressure cable terminals. Directly input height/length for complex bends (e.g., Z-bends). Bending accuracy: ±1°, Repeat bending accuracy: ±0.2°.

Independent Work Surfaces: Allows simultaneous operation of all three units without interference.

Simple Operation: Manual push-button or foot pedal control.

Control Cabinet:

Advanced Control & Protection: Bending angles controlled by imported Siemens PLC NC system. Enhanced protection with 6 Schneider relays, safeguarding system contacts, extending machine life, minimizing downtime, and reducing maintenance costs.

Electrical Safety & Efficiency: Integrated transformer provides effective input/output circuit isolation for electrical safety and prevents interference. Maintains input/output power balance to improve circuit efficiency.

Hydraulic System:

Independent & Efficient: Features three motors and three pumps, enabling each unit to operate independently or concurrently without interference.

Smart Energy Saving: PLC automatically stops motors during idle periods for intelligent power savings and comprehensive energy efficiency.

Machine parameters

Function | 303D | 303C | 303B | 303A | |

Punching | Max. Punching Force (KN) | 300 | 300 | 300 | 300 |

Punching Diameter Range (MM) | Ø4.3-Ø36 | Ø4.3-Ø36 | Ø4.3-Ø36 | Ø4.3-Ø36 | |

Max. Thickness (MM) | 16 | 16 | 16 | 16 | |

Max. Width (MM) | 160 | 160 | 160 | 160 | |

Shearing/ Cutting | Max. Shearing Thickness (MM) | 16 | 16 | 16 | 16 |

Max. Shearing Width (MM) | 160 | 160 | 160 | 160 | |

Vertical Bending | Max. Bending Force (KN) | 500 | 500 | 500 | 500 |

Max. Thickness (MM) | 16 | 16 | 16 | 16 | |

Max. Width (MM) | 160 | 160 | 160 | 160 | |

Horizontal Bending | Max. Width (MM) | 100 | 100 | 100 | 100 |

Max. Angle (Degree) | 90° | 90° | 90° | 90° | |

Out Dimension | MM | 1720*1220*1240 | 1720*1220*1240 | 1720*1220*1240 | 1720*1220*1240 |

First table size | MM | 170x1250 | 1750x1250 | 170x1250 | 1750x1250 |

Second table size | MM | 985X500 | / | 985X500 | / |

Power | KW | 3*4kw | 3*4kw | 1*4kw | 1*4kw |

Weight | KG | 1500kg | 1480kg | 1400kg | 1380kg |

CNC Precision | Bending Precision | ±1° | ±1° | ±1° | ±1° |

Repeat Bending Precision | ±0.5° | ±0.5° | ±0.5° | ±0.5° |

Main component:

| No. | Accessory Name | Quantity | Brand |

|---|---|---|---|

| 2 | PLC | 1 | German Siemens (SIMATIC S7-200) |

| 3 | Touch Screen | 1 | Kunlun Tongtai |

| 4 | Draw-wire Encoder | 1 | Matera |

| 5 | Motor | 3 | Xiangtan Xiangdian |

| 6 | Contactor/Thermal Relay | 3 | Schneider |

| 7 | Relay | 6 | Schneider |

| Transformer | 1 | Lanpu | |

| 8 | Oil Pump | 3 | Taiwan Xin Hong HGP-3A-F11R |

| 9 | Relief Valve | 3 | Taiwan Youtian RF-G02-3-20 |

| 10 | Solenoid Valve | 3 | Taiwan Youtian DSG-03-3C6-20 |

Random Accessories

| No. | Accessory Name | Quantity | Unit |

|---|---|---|---|

| 1 | Punching Mold | 8 | set |

| 2 | Flat Bending Mold | 3 | set |

| 3 | Vertical Bending Mold | 2 | set |

| 4 | U-bend Mold | 1 | set |

| 5 | Oil Can | 1 | set |

| 6 | Hex Key | 1 | set |

| 7 | Hydraulic Seal Ring | 1 | set |

| 8 | Foot Switch | 3 | set |

| 9 | Limit Switch | 2 | pcs |

| 10 | Punching Locating Pin | 1 | pcs |

| 11 | Relay | 2 | pcs |

| 12 | Fuse | 1 | pcs |

| 13 | U-shaped Mold | 1 | set |

| 14 | Embossing Mold | 1 | set |

Certifications:

CE certified (EU standards) & ISO 9001.

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-15 days after payment.

Send Inquiry to This Supplier

You May Also Like

-

CNC Busbar Punching Shearing Machine - Auto 3-in-1 (Punch/Shear/Bend) | CE ISO9001 | 0.1mm PrecisionUS$ 7000 - 9000MOQ: 1 Set

-

Servo CNC Busbar Bending Machine High Precision | Auto Angle Control | CE/ISO9001 for Switchgear BT-CB1600S/CB1600US$ 7000 - 9000MOQ: 1 Set

-

Busbar Leveling Machine | Auto Feed for Bent Busbar Recovery | CE/ISO9001US$ 2500 - 3800MOQ: 1 Set

-

Manual Control Hydraulic Turret-Type 3 in 1 Busbar Processing Machine-Closed Type BT-M303C/BT-M503CUS$ 4000 - 4500MOQ: 1 Set

-

CNC Double Table 3 in 1 Turret-Type Busbar Processing Machine Close Type ISO 9001 BT-C303C/BT-C503C/BT-C803CUS$ 4500 - 5500MOQ: 1 Set

-

Low Cost Universal Testing Machine Laboratory Tensile Testing MachineUS$ 3000 - 10000MOQ: 1 Set

-

Energy-Efficient Food Packing Machine With Low Power Consumption for Cost SavingsNegotiableMOQ: 1 Acre

-

Cnc Milling Machine Parts High Precision Cnc Machine Parts List PdfNegotiableMOQ: 1 Piece

-

Cheap Low Cost Soap Making MachineNegotiableMOQ: 1

-

Commercial Chocolate Conching Machine for Sale Low CostUS$ 7000 - 15000MOQ: 1 Set