| Model series | MCT- 6060Series | ||||

| MCT-6060-1000 | MCT-6060-1500 | MCT-6060-2000 | MCT-6060-3000 | MCT-6060-6000 | |

| Output Power | 1000w | 1500w | 2000w | 3000w | 6000w |

| type | continuous | ||||

| Cutting product accuracy | 0.03mm | ||||

| Minimum hole diameter for cutting through holes | 0.1mm | ||||

| Processing materials | Aluminum, copper, stainless steel metal materials | ||||

| Effective cutting size | 600mm×600mm | ||||

| Fixing method | Pneumatic clamping and fixture support | ||||

| Drive system | Linear Motors |

| Positioning accuracy | ≦+/-0.008mm | ||||

| Repeatability | 0.008mm | ||||

| CCD alignment accuracy | 10um | ||||

| Cutting gas source | Air, nitrogen, oxygen | ||||

| Cutting line width and fluctuation | 0.02mm-0.1mm | ||||

| Cutting surface | Smooth, no burrs, no black edges | ||||

| Overall warranty period | 1 year (excluding wearing parts) | ||||

| weight | 1700Kg | ||||

| Maximum cutting thickness | Stainless steel: 4MM (air) Aluminum plate: 2MM (air) Copper plate: 1.5MM (air) | Stainless steel: 6MM (air) Aluminum plate: 3MM (air) Copper plate: 3MM (air) | Stainless steel: 8MM (air) Aluminum plate: 5MM (air) Copper plate: 5MM (air) | Stainless steel: 10MM (air) Aluminum plate: 6MM (air) Copper plate: 6MM (air) | Stainless steel: 10MM (air) Aluminum plate: 8MM (air) Copper plate: 8MM (air) |

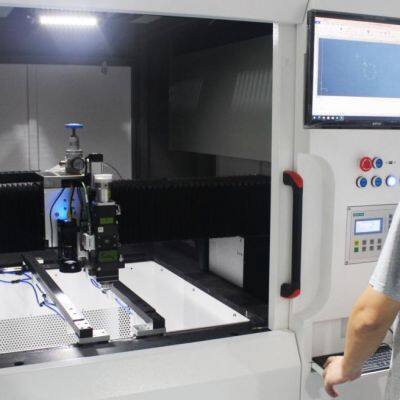

MCT-6060 high-speed precision cutting machine is suitable for precision deformation-free cutting of metals, electronic components, ceramic materials, crystals, carbide, and other precious metal materials. The equipment is driven by imported magnetic suspension linear motors, with high positioning accuracy: large speed regulation range: strong cutting ability: built-in circulating cooling system: preset feed speed: menu-style control: LCD display; users can freely define cutting methods; closed safety cutting room. It is one of the ideal equipment for industrial and mining precision processing enterprises and scientific research institutes to prepare high-quality samples. It adopts a customized fully enclosed cutting control system and uses imported linear motors, which are high-precision, fast, and can handle small products twice as fast as the screw platform: the marble platform frame is integrated with a reasonable structure, safe and reliable, imported linear motor platform, high-speed cutting head, and can be equipped with fiber lasers from any manufacturer; the CNC system adopts a dedicated laser control system and an imported non-contact height tracking system, which is sensitive and accurate, not affected by the shape of the workpiece, and can process any graphics: the guide rail adopts fully enclosed protection to reduce dust pollution, imported high-precision linear motor transmission, and imported high-precision linear guide rail guidance.

Good interactive control system expands the tolerance range and cutting width of processed parts, solves the disadvantage of overall smallness, and has better cutting shape: the cut section is smooth without burrs and deformation, and post-processing is easier: it has a safety alarm and automatically locks the light after removing the workpiece, which is highly safe: it has high positioning accuracy and sensitive response, and adopts shockproof design. There is no need to move the product manually, and cutting is carried out by automatic movement. A variety of power cutting heads can be configured to meet the cutting needs of different products.

Send Inquiry to This Supplier

You May Also Like

-

Q8C Handheld Smart Laser Marking MachineNegotiableMOQ: 1 Set

-

Q8E Handheld Intelligent Laser Marking MachineNegotiableMOQ: 1 Set

-

Q8R Handheld Smart Laser Marking MachineNegotiableMOQ: 1 Set

-

Q8V Handheld Intelligent Laser Marking MachineNegotiableMOQ: 1 Set

-

Q8Z Handheld Smart Laser Marking MachineNegotiableMOQ: 1 Set

-

MZF-C Small Hand-cranked Portable Laser Marking MachineNegotiableMOQ: 1 Set

-

MZF-F Compact Desktop Laser MarkerNegotiableMOQ: 1 Set

-

MZU Ultraviolet Desktop Laser Marking Machine.NegotiableMOQ: 1 Set

-

Q7 Small Hand-cranked Portable Laser Marking MachineNegotiableMOQ: 1 Set

-

Q7 Small Slope Laser Marking MachineNegotiableMOQ: 1 Set