Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating Voltage

220V

Output Frequency

50kHz

Dimensions

15.2cm (L) × 15cm (W) × 3.8cm (H)

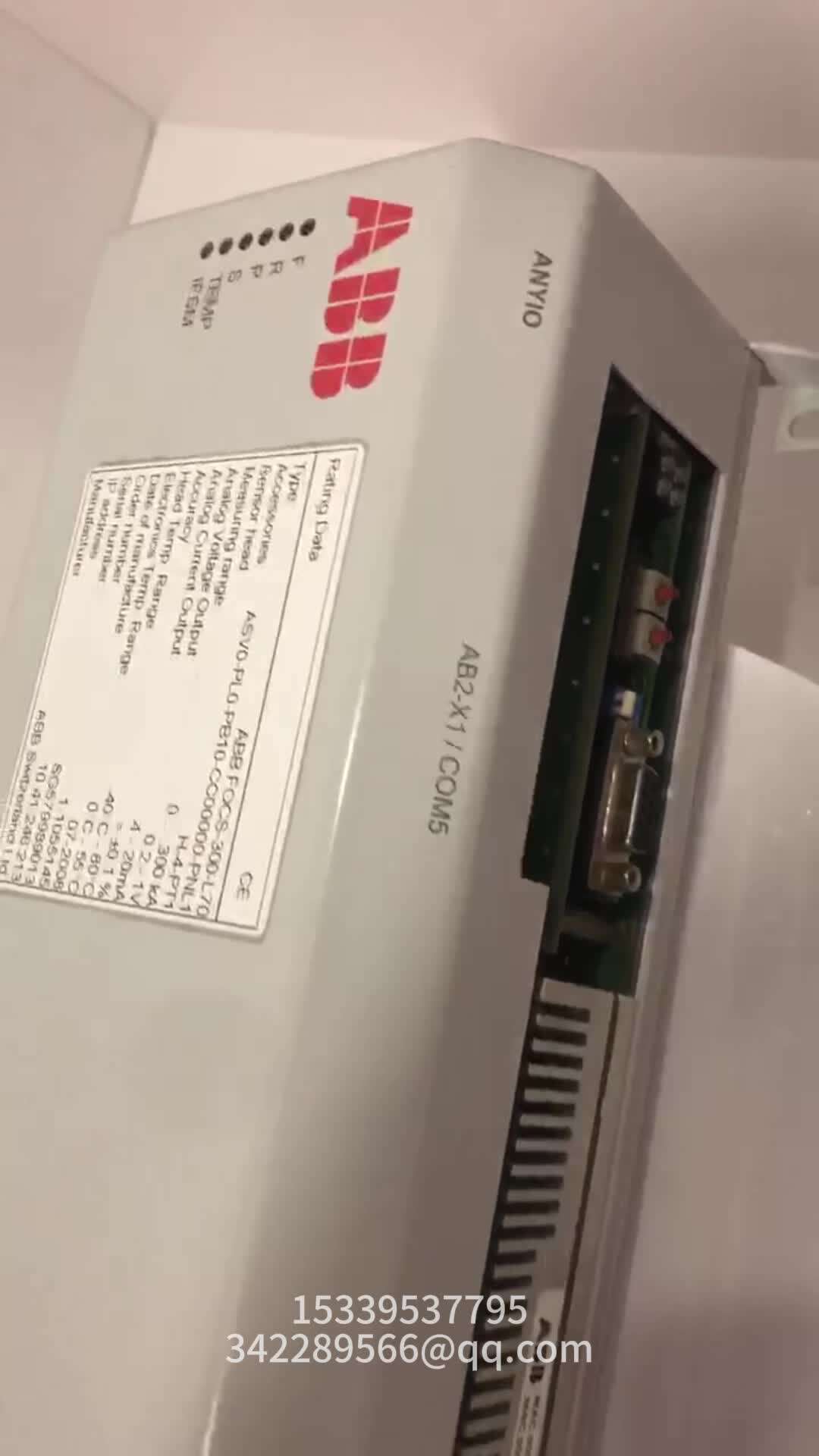

ABB 3BHE017628R0102 PPD115A102Overview

The ABB 3BHE017628R0102 PPD115A102 is a high-performance controller module specially designed for industrial automation systems. With its excellent performance and reliability, it ensures stable and efficient operation in harsh industrial environments such as manufacturing plants and complex production lines. As a key component of ABB's industrial control product portfolio, this module delivers precise control signals based on sophisticated engineering design, widely applied in manufacturing, process control, robotics, and other fields to provide critical support for industrial automation.

Functional FeaturesPowerful Computing and Control Capability

Featuring a bandwidth of up to 200MHz and a sampling rate of 2GS/s, it processes complex control tasks quickly and accurately. When facing high-speed industrial signals, its advanced real-time waveform acquisition technology provides more precise digital measurement results than traditional digital oscilloscopes, enabling clear display and measurement of higher-frequency signals with faster rise times and significantly reducing the possibility of signal aliasing.

Flexible Signal Processing Characteristics

It achieves full bandwidth at scales of 5mV/div and above, outperforming some similar products (e.g., TDS200 has a 20MHz bandwidth limitation at 2mV/div and 5mV/div scales). All models offer a bandwidth sensitivity of 20MHz at 2mV/div, making them ideal tools for analog circuit design and debugging.

User-Friendly Operation and Observation Design

Each channel is equipped with waveform displays, readouts, and cursors in different colors, simplifying the observation of complex multi-channel waveforms. It also features selectable automatic waveform settings, which can automatically detect sine waves, square waves, and video signals, and display these settings via a graphical interface. Users can further select additional settings (e.g., rise/fall edges, video lines/fields, FFT) and automatically display 4 types of parameter measurements based on signal types.

Intelligent Testing Assistance Functions

It includes an online probe connection guide to instruct users to correctly adjust probe compensation and confirm probe attenuation factors, optimizing probe settings for measurement accuracy. Additionally, it offers 11 automatic setup functions covering minimum/maximum values, rise/fall times, +/− pulse widths, period, average value, RMS value, peak-to-peak value, etc., simplifying and accelerating measurements, reducing human errors, and proving particularly useful for repeated testing.

Technical Parameters

Brand: ABB

Model: PPD115A102

Type: Controller Module

Order Number: 3BHE017628R0102

Operating Voltage: 220V

Output Frequency: 50kHz

Certifications: CE, UL

Material: Metal

Dimensions: 15.2cm (L) × 15cm (W) × 3.8cm (H)

Weight: 0.12kg

Application Scope: Steel manufacturing, papermaking, petroleum, thermal power generation, hydropower, etc.

Protection Level: IP65 (dust-tight and protected against water jets, suitable for harsh environments)

Communication Interfaces: Multiple interfaces (unspecified in documents, presumed to include common ones like RS232 for data transmission and system connection)

Working Principle

In an industrial automation system, the PPD115A102 first establishes connections with various sensors, actuators, and control devices via its rich communication interfaces to collect analog and digital signals in real time. For analog signals, the internal front-end circuit preprocesses them—filtering out noise and amplifying the amplitude to meet the input requirements of the subsequent A/D converter. The high-precision A/D converter then converts analog signals to digital signals for transmission to the core microprocessor.

The microprocessor performs high-speed calculations and logical judgments on these digital signals based on pre-programmed control logic and user-defined parameters. For example, in an industrial process control scenario, the microprocessor compares temperature signals from sensors with preset thresholds. If the temperature exceeds the threshold, it sends control signals via digital output channels to drive actuators (e.g., adjusting the speed of a cooling water pump to lower the temperature).

For digital signals, digital input channels monitor real-time status changes of external devices (e.g., switch on/off, equipment start/stop signals) and transmit this information to the microprocessor. After logical operations and judgments, the microprocessor controls external devices' operating states via digital output channels according to control strategies. Throughout operation, the module's electrical isolation and protection circuits continuously prevent external interference from affecting internal circuits, ensuring stable and reliable signal processing and control command output.