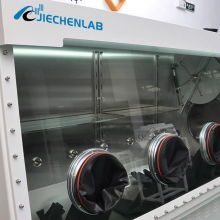

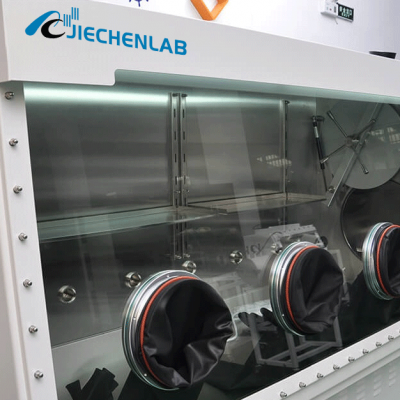

Product Introduction

The dual station purification system glove box 4GBS is a high-performance, high-quality closed cycle working system that automatically absorbs water and oxygen molecules, purifies the working environment, and provides an inert atmosphere with H2O&O2<0.1PPM that can meet your specific experimental needs. This system is an economical circulating purification system designed to meet customer research and development needs;

Structure composition and principle

The 4GBS system includes a sealed enclosure, a set of (large and small) transition chambers that can be evacuated, a rotary vane vacuum pump, and a circulation system integrated with a microcontroller operation panel. The equipped inert gas purification system is equipped with a set of purification columns (fully automatic and renewable) and fans, which are used to purify and maintain the atmosphere inside the glove box, so as to always maintain an environmental atmosphere of H2O&O2 ≤ 0.1PPM inside the box, meeting your experimental needs;

application area

Mainly creating anaerobic and non humid environments for organic metal chemistry, organic synthesis, 3D printing of new material powders, special anaerobic and hydrophobic chemical treatment, biomedical, electronic component processing, solar cell assembly, lithium battery materials and battery assembly experiments, catalyst treatment, pharmaceutical synthesis, nuclear industry, membrane industry, etc;

Performance characteristics

304 stainless steel box design, tempered glass or polycarbonate front window (optional);

• Indicator: Water and oxygen ≤ 0.1ppm;

Leakage rate: ≤ 0.001vol%/h;

The solenoid valve adopts modular design, which reduces leakage rate and is easy to replace;

A large transition compartment with a sliding tray, featuring a unique design for the transition door that is lightweight and easy to open;

• Inert gas purification system; HEPA high-efficiency filter;

SIEMENS microcontroller; SIEMENS operation touch screen, easy to access various functions;;

Closed gas circulation, oil-free and vacuum free; All stainless steel gas flow pipes and fittings;

• Data memo: Automatically record system data;

Replacing manual pressure control with foot pedals;

Automatic pressure control, the working pressure can be set within the range of+12mbar;

Technical Parameter

box

Box size 2640mm (L) * 950mm (W) * 2100mm (H)

Window panel: 8mm thick safety tempered glass or 10mm thick polycarbonate (optional)

Glove opening made of hard aluminum alloy or polyoxymethylene material (optional) with a diameter of 220mm and sealed with an O-ring

Imported butyl gloves

Filter outlet and inlet filters, filtering<0.3 μ m

LED lighting is located at the top of the front window

The final acceptance test shall be conducted according to the standard of leakage rate<0.001 vol%/h

sensor

Oxygen analyzer (optional zirconia) American AII

Accuracy ± 0.1PPM

Electrochemical cells have the advantages of accurate zero point, small drift, less influence of organic solvents on detection results, and low replacement costs (only replacing electrochemical cells). Other types of probes (zirconia heads) can also be replaced according to customer needs

Water analyzer from Vaisala, Finland

Accuracy ± 0.1PPM

Range 0-1000ppm, low drift

Gas purification system

describe

Automatic removal of H2O and O2; single purification column system; Automatic regeneration (optional high-efficiency dual purification column); Closed gas circulation pipeline;

Voltage AC 230V/50-60 Hz, 10A or AC 115 V/50-60 Hz, 20A {optional}

Gas requirements

Working gas: N2, Ar, He (purity ≥ 99.999%); Angry again: H2 accounts for 5% -10%, the rest is working gas

(Purity ≥ 99.999%)

Vacuum pump specifications: rotary vane vacuum pump, equipped with oil mist filter, with pneumatic control; Flow rate: 8m3/h (7 cfm), vacuum degree<2x10-3mbar (optional dry pump)

Circulating unit oil-free high-speed fan: air volume: 0-90m3/h

Valve electromagnetic high vacuum valve

The final acceptance test for port leakage rate shall be conducted according to the standard of leakage rate<0.001 vol%/h

Optional

Organic solvent adsorption system

Material: Stainless steel 1.4 301 (SUS type 304), thickness 3mm;

Internal dimensions: 220mm (Ø) x450mm (H);

High quality activated carbon;

fridge

Independent control system, integrated on the side panel of the box, temperature -35 ℃ C, optional capacity of 18L or 32L;

Main body made of 304 stainless steel plate, with 5 layers of variable compartments;

R404 environmentally friendly refrigerant, imported with original packaging;

The large transition cabin of the heating chamber is equipped with a heating system, with a temperature of 200 ℃ and a temperature control of ± 1 ℃

Send Inquiry to This Supplier

You May Also Like

-

Glove Box B SeriesUS$ 1700MOQ: 1 Piece

-

Laboratory Air Purifying Fume HoodUS$ 2660MOQ: 1 Piece

-

Clean Air Type Pharmaceutical Fume HoodUS$ 2754MOQ: 1 Piece

-

DV2T Touch Screen ViscometerUS$ 1530MOQ: 1 Combo

-

QM-3SP04 Ball Mill(0.4L)US$ 1660MOQ: 1 Piece

-

QM-3SP2 Ball Mill(2L)US$ 1980MOQ: 1 Piece

-

QM-3SP4 Ball Mill(4L)US$ 2250MOQ: 1 Piece

-

QM-3SP20 Ball Mill(20L)US$ 4350MOQ: 1 Piece

-

J-P200 High-speed Miniature Planetary Ball MillUS$ 4500MOQ: 1 Piece

-

J-P400H Micro Planetary Ball Mill Horizontal Tank TypeUS$ 1750MOQ: 1 Piece