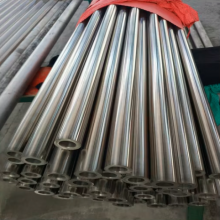

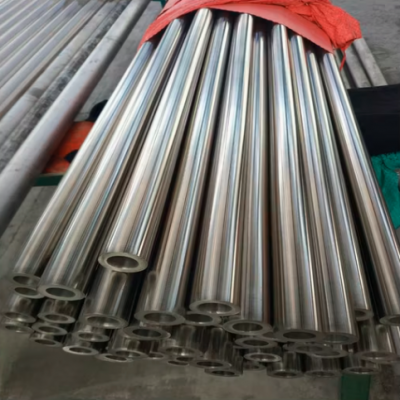

Nickel Alloy Steel Seamless Pipe Incoloy N08825/2.4858 ASTM B423 for Oil & Gas

Material Summarylncoloy 825 is an austenitic nickel-iron-chromium-molybdenum-copper alloy containing high levels of chromium, nickel, copper, and molybdenum to provide high levels of corrosion resistance to both moderately oxidizing and moderately reducing environments. This balance of alloying elements grants this alloy exceptional resistance to both chloride stress corrosion cracking, as well as crevice corrosion and general corrosion. It is the high level of nickel in combination with the amount of molybdenum and copper in this nickel alloy produces substantially improved corrosion resistance in a corrosive environment such as reducing environments compared to stainless steel. The addition of titanium in this alloy also helps to stabilize the alloy against intergranular corrosion. Chloride stress corrosion cracking is a type of localized intergranular corrosion on materials that are put under tensile strength, in high temperatures and in an environment that includes oxygen and chloride ions such as seawater.

As an austenitic, nickel alloy, the material is ductile over a wide range of temperatures from cryogenic to well more than 1000 °F (538 °C). Fabricability is typical for a nickel alloy, with the material readily formable and weldable by a variety of techniques.

| Grade | Ni | Cr | Fe | Mn | C | Cu | Si | S | Al | Ti | Mo |

| Alloy 825 | 38 - 46 | 19.5 - 23.5 | ≥22.00 | ≤1.0 | ≤0.05 | 1.50-3.00 | ≤0.5 | ≤0.03 | ≤0.2 | 0.06 -1.2 | 2.50 - 3.50 |

Mechanical Properties

| Grade | Condition | Tensile Strength | Yield Strength | Elongation(%) |

| N08825 | Annealed | ≥85(586) | ≥35(241) | ≥30 |

| N08825 | Hot finished annealed | ≥75(517) | ≥25(172) | ≥30 |

| N08825 | Cold-worked | ≥85(586) | ≥35(241) | ≥30 |

| N08825 | Hot-forming quality | - | - | - |

APPLICATIONSAlloy 825 is widely used in oil and gas applications. Other uses include chemical process equipment, exhaust systems, and power generation. CRA offers specialty alloy 825 seamless pipe & tube for use in multiple industries and applications, including:

Corrosive well conditions containing the presence of CO2 , H2S, and chlorides, in temperatures up to 300°F, without the presence of sulfur

Tubing, Casing, & Liners

Base Pipe for Sand Screens

Swell Packers

Exhaust Systems

Chemical Processing

Power Generation

Geothermal

Carbon Capture & Sequestration (CCS)

| C | Mn | Fe | P | S | Si | Cu | Ni | Co | Al | Ti | Cr | Nb+Ta | Mo | |

| Inconel 600 | ≤0.15 | ≤1.0 | 6.0-10.0 | ≤0.015 | ≤0.015 | ≤0.5 | ≤0.5 | ≥72.0 | -- | -- | -- | 14.0-17.0 | -- | -- |

| Inconel 601 | ≤0.1 | ≤1.5 | balance | ≤0.02 | ≤0.015 | ≤0.5 | ≤1.0 | 58.0-63.0 | -- | 1.0-1.7 | -- | 21.0-25.0 | -- | -- |

| Inconel 625 | ≤0.1 | ≤0.5 | ≤5.0 | ≤0.015 | ≤0.015 | ≤0.5 | -- | ≥58.0 | ≤1.0 | ≤0.4 | ≤0.4 | 20.0-23.0 | 3.15-4.15 | 8.0-10.0 |

| Inconel 617 | 0.05-0.15 | ≤1.0 | -- | ≤0.012 | ≤0.015 | ≤1.0 | ≤0.5 | ≥44.5 | 10.0-13.0 | 0.8-1.5 | ≤0.6 | 20.0-24.0 | -- | 8.0-10.0 |

| Inconel 690 | ≤0.05 | ≤0.5 | 7.0-11.0 | -- | ≤0.015 | ≤0.5 | ≤0.5 | ≥58.0 | -- | -- | -- | 27.0-31.0 | -- | -- |

| Inconel 718 | ≤0.08 | ≤0.35 | balance | ≤0.015 | ≤0.015 | ≤0.35 | ≤0.3 | 50.0-55.0 | ≤1.0 | 0.2-0.8 | 0.65-1.15 | 17.0-21.0 | 2.8-3.3 | |

| Inconel 725 | ≤0.03 | ≤0.35 | ≤0.015 | ≤0.010 | ≤0.20 | 55.0-59.0 | 19.0-22.5 | 7.0-9.5 | ||||||

| Inconel 750 | ≤0.08 | ≤1.0 | 5.0-9.0 | -- | ≤0.01 | ≤0.5 | ≤0.5 | ≥70.0 | ≤1.0 | 0.4-1.0 | 2.25-2.75 | 14.0-17.0 | 0.7-1.2 | -- |

| Inconel 20 | ≤0.07 | ≤2.0 | balance | ≤0.045 | ≤0.035 | ≤1.0 | 3.0-4.0 | 32.0-38.0 | -- | -- | -- | 19.0-21.0 | 8*C-1 | 2.0-3.0 |

| Inconel 28 | ≤0.02 | ≤2.5 | balance | ≤0.02 | ≤0.015 | ≤1.0 | 0.6-1.4 | 30.0-34.0 | 26.0-28.0 | 3.0-4.0 | ||||

| Inconel 925 | ≤0.03 | ≤1.0 | balance | ≤0.03 | ≤0.03 | ≤0.5 | 1.5-3.0 | 42.0-46.0 | -- | 0.15-0.5 | 1.9-2.4 | 19.5-23.5 | -- | 2.5-3.5 |

| Inconel 926 | ≤0.02 | ≤2.0 | balance | ≤0.03 | ≤0.01 | ≤0.5 | 0.5-1.5 | 24.0-26.0 | -- | -- | -- | 19.0-21.0 | -- | 6.0-7.0 |

| Inconel 825 | ≤0.05 | ≤1.0 | balance | ≤0.02 | ≤0.03 | ≤0.5 | 1.5-3.0 | 38.0-46.0 | -- | ≤0.2 | 0.6-1.2 | 19.5-23.5 | -- | 2.5-3.5 |

| Inconel 800 | ≤0.1 | ≤1.5 | balance | -- | ≤0.015 | ≤1.0 | ≤0.75 | 30.0-35.0 | -- | 0.15-0.6 | 0.15-0.6 | 19.0-23.0 | -- | -- |

| Inconel 800H | 0.05-0.1 | ≤1.5 | balance | ≤0.015 | ≤1.0 | ≤0.75 | 30.0-35.0 | -- | 0.15-0.6 | 0.15-0.6 | 19.0-23.0 | -- | -- | |

| Inconel 800HT | 0.06-0.1 | ≤1.5 | balance | ≤0.015 | ≤1.0 | ≤0.75 | 30.0-35.0 | 0.15-0.6 | 0.15-0.6 | 19.0-23.0 |

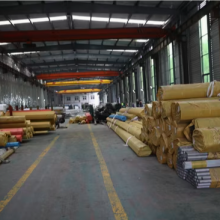

Zhongzheng Stainless Steel Co., Ltd. was established in 2018 with aregistered capital of 20 million yuan. lt is a manufacturing company thatintegrates the production of special materials, manufacturing andprocessing, sales, and technology development. The company covers anarea of 2,000 square meters and has 200 employees. it has built worldclass stainless steel seamless pipe (hot piercing, cold drawing, cold rollingproduction lines, precision steel pipe production lines, and large, mediumand small-sized welded pipe production lines. The company has beencommitted to providing high performance, high precision, hightemperature-resistant, high pressure-resistant, and corrosion-resistantsolutions and technical services for industrial equipment pipeline systems.The company specializes in producing a series of steel pipes, pipe fittingsflanges, etc., such as high-temperature (nickel-based) alloys, austeniticduplex steel, urea grade stainless steel, super stainless steel, etc. Thecompany is equipped with an annual production capacity of 5,000 tons ofstainless steel seamless pipe production line, 7,000 tons of welded pipeproduction line, and 500 tons of pipe fittings production line, etc. lt canoroduce stainless steel seamless pipes with diameters ranging from Φ6 toΦ762 and wall thicknesses ranging from 0.5 to 70 mm, stainless steelwelded pipes with diameters ranging from Φ15 to Φ2200 and wallthicknesses ranging from 0.5 to 80 mm, pipe fittings, and various stainlesssteel ingots, round steel, rough pipes, etc., according to customerrequirements and in accordance with standards such as GB, ASTM, etc.

Packaging & Shipping

Call to Action (CTA)

📞 Contact Now for Best Price!

📧 Email: jane@zjzzgy.cn

💬 WhatsApp: +86 19005872308

Send Inquiry to This Supplier

You May Also Like

-

Good Quality Tube Nickel Based Stainless Steel Hastelloy C-276 Pipe SeamlessUS$ 800 - 1100MOQ: 1 Ton

-

SUS201 304 316 Austenitic Welded Tube Stainless Steel Seamless PipeUS$ 800 - 1100MOQ: 1 Ton

-

Large Diameter 304 Stainless Steel Seamless Pipe Round Tube 304/L/H/Ln 316L/H/Ln/Ti Super Austenitic Stainless Steel Seamless PipeUS$ 800 - 1100MOQ: 1 Ton

-

Alloy 310 & 310S Austenitic Stainless Steel Seamless Tubes in Standards Astma312/A269 for Oil and Gas Industry Pipeline UsingUS$ 800 - 1100MOQ: 1 Ton

-

Ss AISI China Factory Cheap Industrial SS304 316L Grade Stainless Steel Pipe PriceUS$ 1500MOQ: 1 Ton

-

Welding Industrial Material 1.5 Inch 304 316L Stainless Steel Food Grade Tube and PipeUS$ 1600MOQ: 1 Ton

-

Stainless Steel Heat Resistance Industrial Grade Seamless Pipes for Pharmaceutical IndustryUS$ 2000MOQ: 1 Ton

-

304/L/H/Ln 316L/H/Ln/Ti Super Austenitic Stainless Steel Seamless PipeUS$ 800 - 1100MOQ: 1 Ton

-

304/L 316 316L Austenitic Ss Seamless Tube Bright Annealing Stainless Steel TubeUS$ 800 - 1100MOQ: 1 Ton

-

S30432 S31042 N08367 (6Mo) S30803/253mA Super Austenitic Stainless Steel PipeUS$ 800 - 1100MOQ: 1 Ton