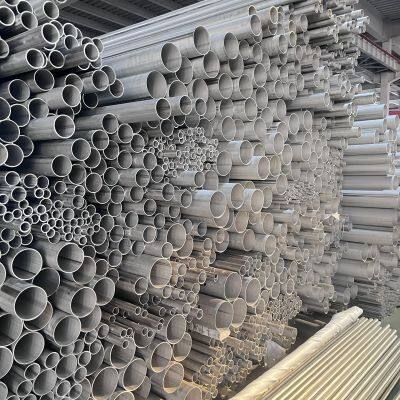

SUS201 304 316 Austenitic Welded Tube Stainless Steel Seamless Pipe

In addition to brand, material and production process, the most important factor affecting the price of stainless steel pipe is the surface treatment of steel pipe. In order to further improve the material properties of pipelines, there are four methods to treat the inner and outer surfaces of pipelines: acid pickling passivation (AP), mechanical polishing (MP), bright annealing (BA) and electrolytic polishing (EP). The experimental data and practice prove that the roughness of pipeline material decreases and the surface adsorbability decreases after surface treatment. So what is the difference between AP, MP, BP and EP stainless steel pipes?

AP (Acid Pickling) pickling treatment

The corrosion resistance of stainless steel is mainly due to the reaction of chromium with oxygen to form a dense protective layer on its surface. The function of pickling is to make it happen in advance to improve the corrosion resistance of stainless steel pipes. During pickling, oil stains and other contaminants on the surface of pipes will be removed. The inner and outer surface of the pipeline is rough and easy to adhere to suspended impurities.

Seamless stainless steel pipe after pickling treatment

MP (Mechanical polishing) mechanical polishing

Polishing wheel or polishing belt polishes the surface of stainless steel pipe with the help of abrasive in polishing agent, so as to achieve smooth polishing effect on the surface of stainless steel pipe. Its brightness and effect depend on the type of processing method. In addition, mechanical polishing can reduce the corrosion resistance although it is more beautiful, so when used in corrosive environment, it needs passivation treatment, and there are often polishing material residues on the surface of steel pipe.

Mechanically polished stainless steel welded pipe

Bright Annealing Bright Annealing Annealing

In the manufacturing process of steel pipes, the grain of grease used for lubrication will also be deformed due to processing. In order to avoid grease residue in steel pipes, argon is used as atmosphere in furnace at high temperature during annealing. By combining argon with carbon and oxygen combustion on the surface of steel pipes, the surface of steel pipes can be further cleaned to produce bright effect. This kind of method uses pure argon annealing to heat and cool rapidly to brighten the bright side. Type A is called glow annealing. Although using this method to brighten the surface can ensure that the steel pipe is fully clean and free from any external pollution. But if the brightness of this surface is compared with other polishing methods, mechanical, chemical and electrolytic will have the feeling of fog. Of course, the effect is also related to the argon content and heating times.

Small caliber stainless steel pipe after bright annealing

EP (Electro Polishing) Electropolishing

Electrolytic polishing is the best way to brighten the surface by means of anodic treatment and by means of electrochemical principle, adjusting the voltage, current, acid composition and polishing time appropriately. It can not only make the surface bright, smooth and clean, but also improve the corrosion resistance of the surface. Of course, its cost and technology are also improved correspondingly.

Electropolished steel pipe

However, because electrolytic polishing will highlight the original state of the steel pipe surface, if there are serious scratches, holes, or slag inclusions, precipitates on the steel pipe surface, it may cause electrolytic failure. The difference between chemical polishing and polishing is that although it is also carried out in acidic environment, there will be no grain boundary corrosion on the surface of steel pipe. The corrosion resistance of steel pipe can be achieved by controlling the thickness of chromium oxide film on the surface.

Company Profile

FAQ

Q: Are you trading company or manufacturer?

A: We are professional manufacturer for steel pipes,and our company also is a very professional and technical foreign trade company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

Q:Will you delivery the goods on time?

A: Yes,we promise to provide best quality products and delivery on time no matter if the price change lot or not. Honesty is our company's tenet.

Q: Do you provide samples ? is it free or extra?

A: The sample could can provide for customer with free,but the freight will be covered by customer account. The sample freight will be returned to customer account after we cooperate.

Q: How can I get your quotation as soon as possible?

A: The email and fax will be checked within 24 hours,meanwhile,Wechat and WhatsApp will be online in 24 hours. Please send us your requirement and order information,specification(Steel grade,size,quantity,destination port),we will work out a best price soon.

Q: Do you have any certifications?

A: Yes,that's what we guarantee to our clients. we have IS09000,IATF16949 certinicate,ISO 14001 certificates etc.Our products are of high quality and we have professional engineers and development team.

Q: What is your terms of payment?

A:Payment

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Call to Action (CTA)

📞 Contact Now for Best Price!

📧 Email: jane@zjzzgy.cn

💬 WhatsApp: +86 19005872308

Send Inquiry to This Supplier

You May Also Like

-

304/L/H/Ln 316L/H/Ln/Ti Super Austenitic Stainless Steel Seamless PipeUS$ 800 - 1100MOQ: 1 Ton

-

304/L 316 316L Austenitic Ss Seamless Tube Bright Annealing Stainless Steel TubeUS$ 800 - 1100MOQ: 1 Ton

-

S30432 S31042 N08367 (6Mo) S30803/253mA Super Austenitic Stainless Steel PipeUS$ 800 - 1100MOQ: 1 Ton

-

Tp310/310S/310h, 1.4841/1.4845, Uns S31000/S31008/S31009 Stainless Steel PipesNegotiableMOQ: 1 Ton

-

Aviation Standard Superalloy AMS 5565 55304 316 Austenitic Stainless Steel Tube Tp321h Cold Drawn Hastelloy X Stainless Steel PipeNegotiableMOQ: 1 Ton

-

Premium Super Austenitic Stainless Steel Pipes for AerospaceNegotiableMOQ: 1 Ton

-

Austenitic Stainless Steel Industrial Grade Seamless Pipe 304 321 316 310S GB/T14976-2012US$ 800 - 1100MOQ: 1 Ton

-

Ss 304 316 38mm for BS Chrome Austenitic Stainless Steel PipeUS$ 800 - 1100MOQ: 1 Ton

-

Aviation Standard Superalloy AMS 316 Zecor-Z Uns38815 Uns S32750 Austenitic Stainless Steel Tube Cold Drawn Hastelloy X Stainless Steel PipeUS$ 800 - 1100MOQ: 1 Ton

-

Stainles Steel Seamless Tubes TP304/31/321/321H Pickled and Annealed Heat Exchanger PipeUS$ 800 - 1100MOQ: 1 Ton