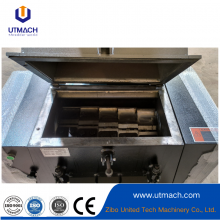

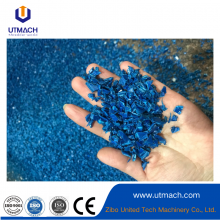

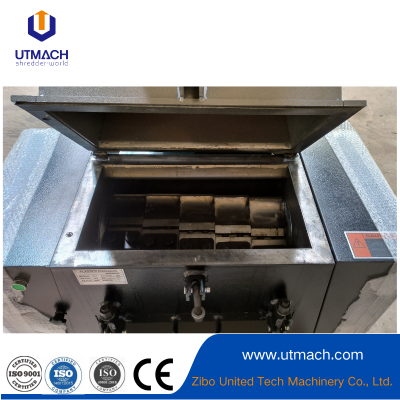

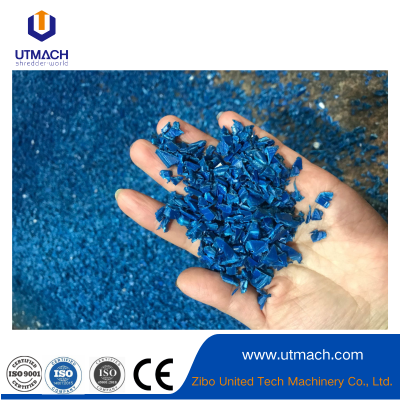

Precision Pellet-forming and Consistent-output Plastic Granulator

A granulator or pelletizer is a specialized machine designed to convert powdery, flaky, or viscous materials into uniform, spherical or cylindrical particles (granules or pellets) through processes like compression, extrusion, or agglomeration. Below is a comprehensive overview of its key aspects:

1. Types of Granulators

Extrusion-Type Pelletizer:

Uses screw-driven extrusion to melt/soften material, which is then cut into pellets.

Common in plastics, chemicals, and food industries.

Roller-Type Granulator:

Relies on rotating rollers to compact powder into sheets, which are crumbled into granules.

Suitable for pharmaceuticals and fine chemicals.

Compression Granulator:

Presses powder into dense granules using rollers or hydraulic pressure.

Often used for brittle materials like coal or fertilizers.

Spray Granulator:

Atomizes liquid onto a moving bed of powder, forming granules through layering.

Used in pharmaceuticals and detergent production.

2. Key Components

Feed System: Delivers raw material (powder, molten plastic, etc.) into the machine.

Screw/Barrel (for Extrusion): Heats and conveys material under pressure.

Die/Nozzle: Shapes extruded material into specific pellet sizes.

Cutting Mechanism: Cuts extruded strips into pellets (e.g., rotary knives).

Cooling System: Rapidly cools pellets to solidify them.

Control Panel: Automates parameters like temperature, speed, and pressure.

3. Working Principle

Material Feeding: Raw material is fed into the hopper.

Processing:

Extrusion: Screw heats/melts material, forcing it through a die.

Compression: Rollers press powder into compacted sheets.

Agglomeration: Liquid binder bonds fine particles into larger granules.

Shaping & Cooling: Extruded material is cut into pellets and cooled.

Output: Uniform granules/pellets are collected for further use.

4. Applications

Plastics Industry: Recycles plastic waste into reusable pellets.

Pharmaceuticals: Forms tablet-ready granules from active ingredients.

Chemicals & Fertilizers: Produces uniform pellets for easy handling/storage.

Food Industry: Pelletizes powders (e.g., milk, spices) for packaging.

Biomass Energy: Compacts wood/straw into biofuel pellets.

5. Key Features

Precision Control: Adjustable speed, temperature, and pressure for consistent output.

High Capacity: Suitable for large-scale industrial production.

Material Versatility: Can process plastics, metals, ceramics, and organic materials.

Energy Efficiency: Modern designs minimize power consumption.

Safety Systems: Overload protection, emergency stops, and dust extraction.

6. Technological Advancements

Automation: PLC/HMI systems for real-time monitoring and adjustment.

Twin-Screw Extruders: Improve mixing efficiency for complex formulations.

Underwater Pelleting: Cools pellets instantly for higher throughput.

Sustainability: Energy recovery systems and low-emission designs.

7. Maintenance & Safety

Regular Cleaning: Prevent material buildup, especially in food/pharma applications.

Component Inspection: Check screws, rollers, and dies for wear.

Safety Protocols: Lockout/tagout procedures, dust masks, and thermal protection.

8. Terminology

Granulation: Process of forming particles from powder.

Pelletizing: Extrusion-based method for plastics/chemicals.

Agglomeration: Particle growth via liquid or heat bonding.

Spheronitizing: Rounding particles for better flow/handling.

Send Inquiry to This Supplier

You May Also Like

-

Non-stop Continuous and Precision Pellet-forming Plastic GranulatorNegotiableMOQ: 1 Set

-

Supercritical-processed and Fully-automated Plastic GranulatorNegotiableMOQ: 1 Set

-

Recyclate-specialized and Modular-designed Plastic GranulatorNegotiableMOQ: 1 Set

-

Clean-production and Precision Controlled Plastic GranulatorNegotiableMOQ: 1 Set

-

Intelligently Temperature-controlled and Wear-resistant Lined Plastic GranulatorNegotiableMOQ: 1 Set

-

Modular-designed and Recyclate-specialized Plastic GranulatorNegotiableMOQ: 1 Set

-

Heat-sensitive Optimized and Recipe-storing Plastic GranulatorNegotiableMOQ: 1 Set

-

Multi-functional and Low-maintenance Plastic GranulatorNegotiableMOQ: 1 Set

-

Corrosion-resistant and High-capacity Plastic GranulatorNegotiableMOQ: 1 Set

-

Environmentally-friendly and Customizable Industrial-grade Plastic GranulatorNegotiableMOQ: 1 Set