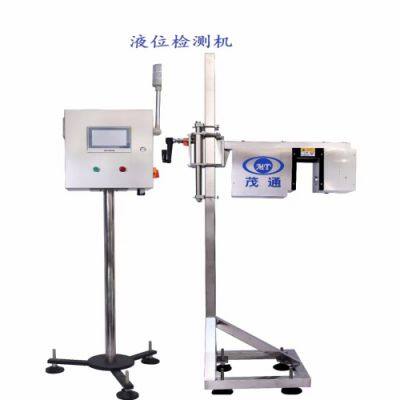

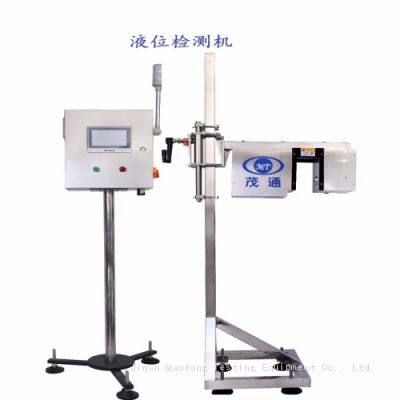

Easy to Pull Can Product Liquid Level Detection Equipment, High-speed Liquid Level Inspection Machine

Easy to pull can product liquid level detection equipment, high-speed liquid level inspection machine

The liquid level detection equipment for cans plays an important role in beverage, beer and other filling production lines, and its core advantages are mainly reflected in the following aspects:

---1. High precision detection to ensure product quality-Precise control of liquid level: Advanced technologies such as optics, ultrasound, or gravity sensing are used to detect liquid level height in real time, with an accuracy of up to ± 0.5mm, avoiding insufficient liquid level (affecting consumer experience) or excessive liquid level (causing overflow or poor sealing).-Reduce product waste: By precisely controlling the filling volume, the scrap rate caused by insufficient liquid level can be reduced, saving raw material costs.

---2. Improve production efficiency and automation level-High speed online detection: adapted to high-speed production lines (such as over 1000 cans per minute), providing real-time feedback data to ensure synchronization with the production line rhythm.-Automation integration: No manual intervention required, seamlessly integrated into PLC or industrial IoT systems, achieving full process automation control and reducing labor costs.

---3. Flexible compatibility and adaptabilityMulti specification support: Through modular design or parameter adjustment, it can adapt to different capacities (such as 250ml, 330ml, 500ml, 1000ml) and shapes of cans.Adaptation to complex environments: Strong anti-interference ability, capable of stable operation in industrial environments with humidity, vibration, or changes in lighting.

---4. Advantages of non-contact detection technology-Avoid contamination: Optical or ultrasonic testing does not require contact with the tank and complies with food hygiene and safety standards (such as HACCP, FDA).-Non destructive testing: does not damage the tank or label, ensuring the integrity of the product's appearance.

---5. Data traceability and quality management-Real time monitoring and alarm: When abnormal liquid level is detected, an alarm or shutdown is immediately triggered to prevent the production of batches of defective products.-Data recording and analysis: Store detection data, support production batch traceability and quality analysis, and assist in optimizing process flow.

---6. Reduce long-term operating costs-Low maintenance cost: Non contact sensors have a long lifespan and simple daily maintenance.-Energy saving and environmental protection: reducing raw material waste caused by excessive filling, in line with the concept of green production.

---7. Enhance brand reputation-Consistency guarantee: Ensure that the liquid level of each can of product is uniform, avoid consumer complaints, and maintain brand image.-Complies with industry standards: meets the quality supervision requirements of the food and beverage industry both domestically and internationally.

---Typical application scenarios-Quality control of filling line: Real time detection and interception of non-conforming products during the filling process.-Production line upgrade: replacing traditional manual sampling and improving the level of intelligence.-New product development support: Quickly adapt to new tank types and shorten product launch cycles.

---summarizeThe liquid level detection equipment for cans, with its advantages of high precision, automation, and dataization, helps enterprises achieve cost reduction and efficiency improvement, ensure quality compliance, and support flexible production needs. It is one of the essential core equipment for modern filling production lines.

Send Inquiry to This Supplier

You May Also Like

-

PET Bottle Cap Liquid Level Spray Code Detection Equipment On-line Vision DetectorNegotiableMOQ: 1 Set

-

On-line Leak Detector for Leak Detection of Bagged ProductsNegotiableMOQ: 1 Combo

-

Maotong Visual Inspection Equipment All-in-one Machine for Online Detection of PET BottlesNegotiableMOQ: 1 Combo

-

3000470-510 Detect Liquid Level Height/such As Ultrasonic Sensors or Float SwitchesUS$ 3868.00MOQ: 1 Pallet

-

Condensate Auto Drain Valve Zero Compressed Air Consumption Capacitive Electronic Liquid Level Sensor DetectionNegotiableMOQ: 1

-

Liquid Detect Ultrasonic Tank Level SensorUS$ 100 - 120MOQ: 1 Set

-

Liquid Level Ultrasonic Test EquipmentUS$ 1 - 700MOQ: 1 Unit

-

Leak Detection Liquid for Level Measurement,data Logger for Flow MeterUS$ 50 - 100MOQ: 1 Piece

-

Water Level Sensor Probe Module Depth of Detection Liquid Surface Height Water Tank Level SensorUS$ 0.82 - 0.82MOQ: 100 Units

-

Geological Equipment Inclination Detection Switch Sensor Level Control WaterproofNegotiableMOQ: 1 Piece