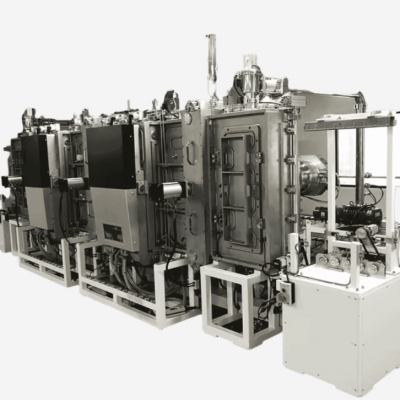

SIMVACO Perovskite Solar Cell PVD Magnetron Sputtering Machine Thin Film Deposition System

SIMVACO magnetron sputtering equipment is designed for precision thin-film deposition of perovskite materials, widely used in advanced solar cell manufacturing. This system delivers high-efficiency and uniform coatings, enabling consistent layer quality essential for improving energy conversion in perovskite solar cells.

Precision Magnetron Sputtering: Ensures controlled and uniform deposition of perovskite thin films with optimized layer thickness and material density.

Large Substrate Compatibility: Handles substrates up to 600×600 mm, supporting R&D and pilot-scale production for solar cell manufacturing.

Stable Vacuum Performance: Achieves vacuum levels of ≤1×10-4 Pa, ensuring a clean process environment that minimizes contamination and defects.

Real-Time Process Monitoring: Integrated systems track film thickness, deposition rate, and vacuum stability for repeatable and precise results.

Multi-Layer Deposition: Supports the creation of multi-stack thin-film structures critical for efficient perovskite solar cell production.

Substrate Heating Control: Adjustable heating up to 350°C enhances film crystallization and adhesion, improving overall solar cell performance.

Technical SpecificationsApplications

Perovskite Solar Cells: Uniform and stable thin-film deposition for improving solar energy conversion efficiency.

Multi-Layer Solar Coatings: Deposition of conductive and functional layers required for advanced solar cell architectures.

Research and Development: Ideal for perovskite material testing, prototyping, and pilot-scale production.

Optoelectronic Devices: Thin-film coatings for sensors, flexible displays, and related optoelectronic components.

High Uniformity: Delivers consistent coating thickness and material properties across the entire substrate surface.

Scalable Production: Designed for large substrates, ensuring adaptability from laboratory to pilot-scale manufacturing.

Precision Control: Real-time monitoring systems ensure accuracy and repeatability for complex multi-layer thin films.

Material Efficiency: Optimized sputtering processes minimize target material waste and enhance deposition performance.

Our magnetron sputtering equipment for perovskite coating represents advanced technology for high-precision deposition critical to next-generation solar cell manufacturing. With stable vacuum performance, substrate heating, and multi-layer capability, it meets the demands of research and industrial applications focused on improving solar efficiency. For more information or to request a demonstration, please contact us today!

Contact UsContact SIMVACO today to learn more about our advanced Perovskite Thin Film Coating and how it can support your manufacturing goals.

Send Inquiry to This Supplier

You May Also Like

-

SIMVACO Eco-Friendly Vacuum Evaporation Coating Machine for Plastic Christmas ProductsUS$ 50000 - 60000MOQ: 1 Set

-

SIMVACO Advanced Vacuum Evaporation Coating Equipment for Automotive LightingUS$ 70000 - 1000000MOQ: 1 Set

-

SIMVACO High-Performance Metal Ceramic PVD Coating Machine Hard Vacuum CoatingUS$ 350000 - 500000MOQ: 1 Set

-

SIMVACO Perovskite Solar Cell PVD Coating Machine Thermal Evaporation Vacuum CoatingUS$ 200000 - 400000MOQ: 1 Set

-

GELGOOG Chocolate Sugar Coating Machine / Chocolate Coating Machine For ChocolateNegotiableMOQ: 1 Set

-

Stainless Steel Coil Colored Rolled Gold Finished 0.3-3.0mm PVD Color 304 Stainless Steel Coil 8K MirrorNegotiableMOQ: 1 Ton

-

High-Reflectivity PVD Coated Decorative Stainless Steel CoilUS$ 1800 - 2150MOQ: 1 Ton

-

Portable Adhesion Tester for Coatings Digital Adhesion Tester for Paint and Coatings Adhesion Bond Strength Testing MachineUS$ 1100 - 1200MOQ: 1 Set

-

PVC PE-Coated Zigzag Wiggle Wire Making Machine Line, Greenhouse Spring Wire Production EquipmentNegotiableMOQ: 1 Set

-

Custom Plastic Parts Plastic Parts For Assembly Surface Painting / PolishingNegotiableMOQ: 1 Piece