Home > Products > PVD Coating Machine > SIMVACO Large Glass Anti-Reflection Sputter Deposition Production Line PVD Coating Machine

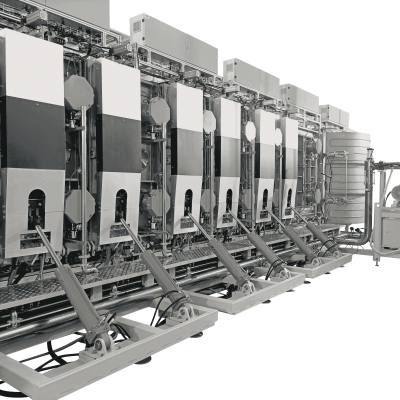

SIMVACO Large Glass Anti-Reflection Sputter Deposition Production Line PVD Coating Machine

- Shanghai

- T/T L/C

You May Like

-

SIMVACO Horizontal PVD Coating Continuous Production Line Metal & Glass Substrate Magnetron Sputtering

-

SIMVACO Large-Area Multi-Arc Ion Decorative Coating Machine for Metal Surfaces

-

SIMVACO Eco-Friendly Vacuum Evaporation Coating Machine for Plastic Christmas Products

-

SIMVACO Advanced Vacuum Evaporation Coating Equipment for Automotive Lighting

-

SIMVACO High-Performance Metal Ceramic PVD Coating Machine Hard Vacuum Coating

-

SIMVACO Perovskite Solar Cell PVD Coating Machine Thermal Evaporation Vacuum Coating

Product Details

| Brand Name | SIMVACO | Place of Origin | China | |

| Type | Coating Production Line | Certification | ISO9001 | |

| After-sales Service Provided | Engineers available to service machinery overseas | Warranty | 1 year | |

| Condition | New | Coating | Vacuum Coating | |

| Substrate | Glass |

Product Description

The large glass anti-reflection sputter deposition production line is an advanced vacuum coating system designed for the efficient and precise application of high-quality anti-reflective (AR) coatings on large glass panels. Utilizing magnetron sputtering technology, this system ensures uniform thin-film deposition, stable process control, and scalability for industrial-scale production.

Key Features

Magnetron Sputtering Technology: Provides controlled and consistent thin-film deposition for anti-reflection coatings, improving optical transparency and reducing surface reflectivity.

High Uniformity: Achieves a coating uniformity of ±2% across large-area substrates, ensuring consistent performance.

Large Substrate Compatibility: Supports glass panels up to 1,500×1,200 mm for large-scale production.

Multi-Layer Coating Capability: Enables the deposition of multi-layer AR structures using materials such as SiO₂, TiO₂, and other optical-grade materials.

Real-Time Process Monitoring: Integrated monitoring systems for plasma stability, film thickness, and deposition rate ensure reliable and repeatable coating quality.

Inline Production System: Continuous inline processing for high throughput and reduced production downtime.

Technical Specifications

| Parameter | Specification |

|---|---|

| Deposition Technology | Magnetron Sputtering |

| Coating Material | SiO₂, TiO₂, and other AR materials |

| Substrate Type | Glass panels |

| Substrate Size | Up to 1,500×1,200 mm |

| Coating Uniformity | ±2% |

| Film Thickness Range | 20nm - 500nm |

| Deposition Speed | Up to 5nm/s |

| Vacuum Pressure | ≤1×10⁻⁴ Pa |

| Automation | Fully automated inline system |

| Heating Capability | Up to 350°C |

Applications

Display Panels: AR layers for large-format displays, improving optical clarity and reducing glare.

Automotive Glass: Anti-reflection coatings for windshields and interior screens to enhance visibility.

Optical Glass: Precision coatings for lenses and optical components requiring low reflectivity.

Architectural Glass: Anti-reflective coatings for windows, facades, and skylights to enhance light transmission.

Process Advantages

Stable Coating Process: Real-time control of deposition parameters ensures consistent film quality and thickness.

Scalable Production: Designed for large-area glass panels, meeting the needs of high-throughput production.

Material Efficiency: Optimized sputtering processes minimize material waste while maximizing coating coverage.

Energy Management: Integrated systems reduce power consumption, enhancing cost-efficiency during continuous production.

With its robust technical specifications and focus on high-quality output, it is the ideal solution for industries seeking reliable and efficient anti-reflective coatings on large glass panels. Utilizing precise magnetron sputtering technology, real-time process control, and compatibility with large glass substrates, SIMVACO provides a reliable solution for enhancing optical performance in automotive, display and architectural industries.

Contact Us

- Zhejiang Shengbo Intelligent Equipment Co., Ltd.

- Contact nameSimon Chat Now

- AddressHaining, Jiaxing, Zhejiang

Product Categories

| PVD Coating Machine |

New Products

Popular Searches

- vacuum pump

- pvd vacuum coating machine

- plating machine

- vacuum coating equipment

- plating equipment

- coating system

- vacuum metallizing plant

- vacuum coating machine

- color coating machine

- titanium coating machine

- gold plating machine

- coating equipment

- film coating machine

- vacuum metallizing machine

- gold coating machine

- vacuum coating

- plasma coating machine

- magnetron sputtering

- vacuum plating system

- vacuum metallizing system

- deposition machine

- magnetron sputtering coating machine

- magnetron sputtering vacuum coating machine

- coating system machine

- automotive control

- pvd vacuum coating machine

- plating machine

- vacuum coating equipment

- plating equipment

- coating system

Recommended Products

- SIMVACO Perovskite Solar Cell PVD Magnetron Sputtering Machine Thin Film Deposition System

- SIMVACO Perovskite Solar Cell PVD Coating Machine Thermal Evaporation Vacuum Coating

- SIMVACO High-Performance Metal Ceramic PVD Coating Machine Hard Vacuum Coating

- SIMVACO Advanced Vacuum Evaporation Coating Equipment for Automotive Lighting

- HY-K09 Large Motor Stator and Rotor Tunnel Electrostatic Powder Spraying Production Line

- HY-K09 Electric Toothbrush 3 Small Stator and Rotor Electrostatic Powder Coating Machine

- SIMVACO Eco-Friendly Vacuum Evaporation Coating Machine for Plastic Christmas Products

- SIMVACO Large-Area Multi-Arc Ion Decorative Coating Machine for Metal Surfaces

- SIMVACO Horizontal PVD Coating Continuous Production Line Metal & Glass Substrate Magnetron Sputtering

- SIMVACO Tool Superhard Coating Ion Plating Machine Enhanced Hard Film Deposition Hardware

- Powder Coating Machine ,coating Machine,powder Coating, Powder Output 300-400g/min,powder Paint

- HXC-600A Factory Direct Sales In Line With Human Mechanics Design Powder Cartridge Electrostatic Powder Metal Coating Machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Coating Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Simon

Hi there! Welcome to my shop. Let me know if you have any questions.

Simon

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile