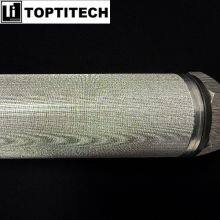

SUS304 Sintered Multilayer Wire Mesh Filter for Cooling Water Filtration

Product Introduction

TOPTITECH’s SUS304 Sintered Multilayer Wire Mesh Filter for Cooling Water Filtration delivers precision filtration through its gradient-pore architecture, combining corrosion-resistant SUS304 alloy with vacuum diffusion bonding technology. Unlike conventional 316L variants, this filter optimizes cost-performance ratios while maintaining chloride resistance in industrial cooling systems; its multilayer stacking integrates protective, separation, and drainage layers to achieve sustained particulate retention without flow decay. Customizable end connections ensure seamless integration with diverse piping configurations, while the metallurgical bonding process eliminates media migration risks even under thermal cycling conditions.

Engineered for hydrodynamic stability, TOPTITECH’s SUS304 Sintered Multilayer Wire Mesh Filter for Cooling Water Filtration features a self-supporting structure capable of bidirectional flow operations. The SUS304 substrate offers built-in passivation against biofilm adherence, while the sintered surfaces improve mechanical integrity against hydraulic shocks. Applications span from HVAC chillers to chemical process cooling loops, where its balanced porosity and anti-fouling properties reduce maintenance frequency. Advanced surface finishing techniques further mitigate scaling tendencies, making it a durable alternative to polymer or ceramic filters in high-temperature water treatment scenarios.

Specifications

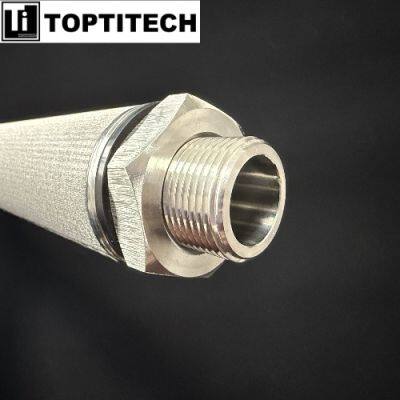

Material: SUS304

Pore size: 2um

Size:φ50*670mm

Connector: Customized according to the drawings

Technique: Sintering

Features

Metallurgical Bonding via Vacuum Sintering

By creating diffusion-bonded connections through regulated high-temperature sintering, TOPTITECH’s SUS304 Sintered Multilayer Wire Mesh Filter removes the possibility of media displacement. This process ensures fixed aperture geometry under cyclic pressure, critical for aerospace hydraulic systems and medical-grade filtration, where structural failure is intolerable.

Multi-Layer Gradient Porosity Design

The filter is designed to combine precision filtration layers with coarse protection meshes using stacked layers of different weave densities. This architecture enables bidirectional contaminant retention while maintaining hydrodynamic efficiency, outperforming single-layer wire screens in high-viscosity fluid applications.

Enhanced Material Properties

Post-sintering thermal treatment improves tensile strength and corrosion resistance through recrystallization. The SUS304 substrate demonstrates superior chloride ion tolerance compared to standard 316L alloys, particularly in marine cooling systems with elevated salinity levels.

Self-Supporting Structural Integrity

Integrated drainage layers and sintered interfaces create a rigid framework capable of withstanding reverse flushing pressures. This monolithic construction prevents layer delamination during pulsating flow conditions, ensuring long-term dimensional stability.

High-Temperature Operational Resilience

The sintered matrix maintains pore geometry under thermal cycling, resisting creep deformation in foundry cooling loops and steam-injected processes. Oxide layer formation during sintering further enhances oxidation resistance at elevated temperatures.

Sustainable Maintenance Protocol

Ultrasonic cleaning restores original permeability without mechanical degradation, supporting multiple regeneration cycles. The fully metallic composition permits arc furnace recycling, aligning with circular manufacturing principles.

Applications of SUS304 Sintered Multilayer Wire Mesh Filter in Cooling Water Filtration

Biofilm Mitigation in Open Recirculating Cooling Towers

Through carefully regulated high-temperature sintering, the SUS304 Sintered Multilayer Wire Mesh Filter creates diffusion-bonded joints that remove the possibility of media displacement. Its electro-polished surface topology disrupts bacterial adhesion mechanisms, critical for systems using non-chlorinated biocides in food processing plants.

Chloride Stress Corrosion Cracking (CSCC) Prevention

In coastal power plant condensers handling brackish coolant, the filter’s SUS304 substrate acts as a sacrificial barrier against chloride ion penetration. It safeguards copper-nickel alloy tubing from pitting initiation, particularly in mixed-metallurgy cooling circuits with galvanic corrosion risks.

Turbidity Control for Once-Through Cooling Systems

The gradient-pore structure traps suspended silts and carbonate precipitates in steel mill blast furnace cooling loops, maintaining optical clarity for laser-based flow monitoring equipment. Multidirectional flow compatibility allows installation in vertical/horizontal pipe orientations without performance deviation.

Scale Particle Arrestance in High-Hardness Water

Industrial chillers operating with calcium-rich makeup water utilize the filter’s interlocking mesh layers to capture crystalline nuclei before they reach plate heat exchangers. This application minimizes frequency of EDTA-based chemical cleaning in district cooling networks.

Erosion-Corrosion Protection in Hydrodynamic Cavitation Zones

The material degradation is accelerated by the sintered mesh, which is positioned upstream of centrifugal pump intakes and dissipates micro-bubble implosion energy. This application proves vital for paper mill cooling systems experiencing frequent flow velocity fluctuations.

Microplastic Filtration in Environmental Control Circuits

The filter’s 2um retention capability addresses synthetic fiber contamination in data center immersion cooling fluids, where polymer degradation products threaten pump seal integrity and dielectric fluid stability.

Magnetic Particle Separation in Hybrid Cooling Systems

When paired with electromagnetic pre-filters in automotive test bench coolers, the sintered mesh provides secondary capture of ferrous wear debris below 100μm, extending glycol-based coolant service intervals by 2-3 operational cycles.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer's designated place without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH -- BAOJI YINGGAOCO., LTD

Website:/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Powder Sinter Filters From ToptitechUS$ 3 - 100MOQ: 1 Piece

-

φ300*500mm Multilayer SS316L Sintered Wire Mesh Filter BarrelUS$ 3 - 100MOQ: 1 Piece

-

Sintered Porous Metal Powder Filters ToptitechUS$ 3 - 100MOQ: 1 Piece

-

Sintered Metal Gas Diffusion Stones ToptitechUS$ 3 - 100MOQ: 1 Piece

-

Stainless Steel Pleated Filter Cartridge From ToptitechUS$ 3 - 100MOQ: 1 Piece

-

The Stainless Steel Filter Powder MetallurgyUS$ 3 - 100MOQ: 1 Piece

-

Multi-Layer Metal Sintered Mesh Filter ElementUS$ 3 - 100MOQ: 1 Piece

-

Deep Pleated Filter Cartridges for Air Oil FiltrationUS$ 3 - 100MOQ: 1 Piece

-

Sintered Stainless Steel Porous Metal Filter Tube Filter CupUS$ 3 - 100MOQ: 1 Piece

-

Muti-layer Stainless Steel Sintered Mesh Filter ElementUS$ 3 - 100MOQ: 1 Piece