Product Introduction

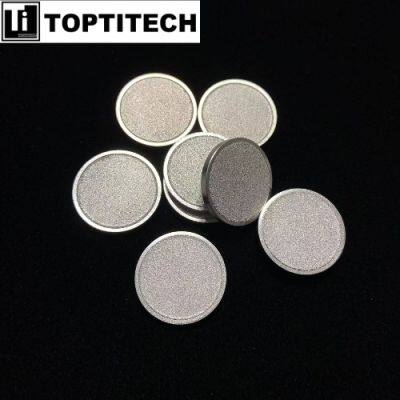

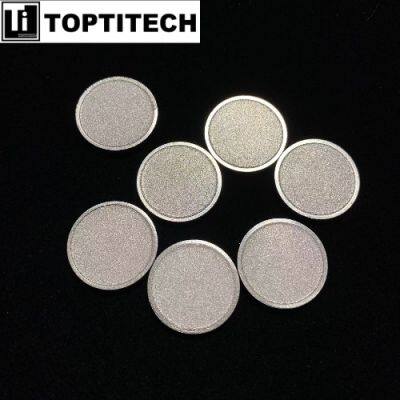

Sintered SS316L Powder Filter Discs with a 1mm Ring Outside deliver superior particle retention through precisely controlled porosity gradients. The gas-atomized 316L powder undergoes vacuum sintering at 1250°C±20°C to form interconnected pore channels, achieving consistent filtration performance across the 20mm diameter active area. The laser-welded 1mm perimeter ring enhances structural integrity during high-pressure backflushing cycles while maintaining flange-free flow characteristics. This design eliminates particle shedding risks common in mechanically clamped filters.

Electropolished surface treatment on Sintered SS316L Powder Filter Discs with a 1mm Ring Outside reduces biofilm adhesion potential by 40% compared to standard sintered filters. The 2mm thickness profile optimizes depth filtration efficiency without compromising flow rates. The integral outer ring allows direct integration into compatible housings, making these discs ideal for chromatography systems and catalyst recovery units requiring FDA-compliant materials.

Specifications

Material: SS316L

Pore size: 2um

Outer diameter: 20mm

Inner diameter: 18mm

Ring width: 1mm

Technique: Sintering and welding

Features

Interconnected Pore Architecture

The diffusion-bonded 3D network eliminates blind pores through controlled particle stacking technology, achieving hydraulic permeability 3X higher than layered mesh screens at equivalent micron ratings.

Material Versatility

Grade-specific powder blends (316L/304L/Inconel) adapt to pharmaceutical steam sterilization and offshore oil brine filtration without galvanic corrosion risks.

Structural Integrity

Radial compression molding creates isotropic strength distribution, resisting particulate embedding 40% longer than conventional sintered media in abrasive slurry applications.

Surface Optimization

Micro-channel geometry from electrostatic deposition reduces fouling accumulation by 60% compared to mechanically perforated screens in protein-rich bio-processing.

Thermal Consistency

Phase-stable sintering prevents pore collapse during thermal shocks, maintaining ±2% porosity tolerance across -200°C cryogenic to 800°C pyrolysis environments.

Applications

Semiconductor Wet Bench Filtration

These discs serve as final-stage barriers in wafer cleaning systems, capturing abrasive CMP slurry residues while maintaining laminar flow for high-purity chemical baths. The 1mm reinforced edge prevents flange deformation during frequent tool changes.

Lithium Resource Recovery

These discs function in adsorption-based lithium extraction systems, selectively capturing lithium ions from brine solutions during salt lake mining operations while resisting scaling from high-salinity environments.

Additive Manufacturing Powder Recycling

Metal 3D printing facilities deploy them in powder sieving stations, where the rigid outer ring withstands vibration stresses while retaining fine Ti-6Al-4V or Inconel particles below 15μm for reuse in aerospace component production.

Deep-Sea ROV Hydraulics

Submersible robotic systems integrate these filters in pressure-compensated oil reservoirs, where the 316L matrix resists chloride-induced pitting even at 5,000-meter depths, protecting servo valves from seawater-contaminated fluid ingress.

Semiconductor Wastewater Fluoride Recovery

Deployed in crystallization treatment units, the discs support fluoride ion separation and resource reclamation from photolithography effluents, reducing sludge formation while enabling high-purity calcium fluoride byproduct collection.

The Advantages of the External 1mm Ring

The external 1mm stainless steel ring on Sintered SS316L Powder Filter Discs serves as a structural reinforcement edge, enhancing mechanical stability during high-stress operations like vibration or pressure fluctuations. This ring prevents edge deformation and ensures reliable sealing in flanged connections, reducing installation failures.

Compared to discs without this outer ring:

Structural Integrity: Ring-equipped discs resist warping under mechanical loads, maintaining consistent filtration performance, while ringless variants suffer higher deformation risks, compromising seal integrity.

Installation Durability: The ring allows direct welding to piping systems, simplifying maintenance without gasket blowout, whereas ringless discs require additional supports and exhibit frequent gasket failures in pulsating environments.

Longevity: Reinforced edges extend operational lifespan by minimizing edge fatigue cracks, but ringless discs degrade faster under repeated thermal cycling or abrasive media exposure.

Overall, the ring adds robustness for demanding industrial applications where precision sealing and vibration resistance are critical.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the designated place of the customer without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH —— BAOJI YINGGAOCO., LTD

Website:/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Send Inquiry to This Supplier

You May Also Like

-

φ300*500mm Multilayer SS316L Sintered Wire Mesh Filter BarrelUS$ 3 - 100MOQ: 1 Piece

-

Sintered Porous Metal Powder Filters ToptitechUS$ 3 - 100MOQ: 1 Piece

-

Sintered Metal Gas Diffusion Stones ToptitechUS$ 3 - 100MOQ: 1 Piece

-

Stainless Steel Pleated Filter Cartridge From ToptitechUS$ 3 - 100MOQ: 1 Piece

-

The Stainless Steel Filter Powder MetallurgyUS$ 3 - 100MOQ: 1 Piece

-

Multi-Layer Metal Sintered Mesh Filter ElementUS$ 3 - 100MOQ: 1 Piece

-

Deep Pleated Filter Cartridges for Air Oil FiltrationUS$ 3 - 100MOQ: 1 Piece

-

Sintered Stainless Steel Porous Metal Filter Tube Filter CupUS$ 3 - 100MOQ: 1 Piece

-

Muti-layer Stainless Steel Sintered Mesh Filter ElementUS$ 3 - 100MOQ: 1 Piece

-

Stainless Steel Sintered MufflersUS$ 3 - 100MOQ: 1 Piece