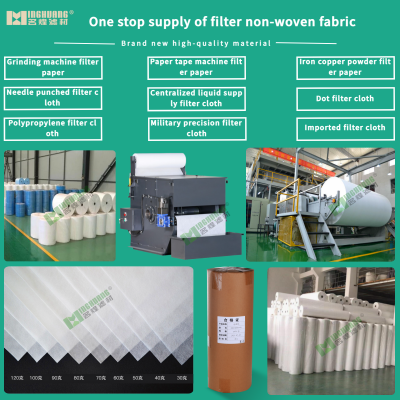

Industrial Grinder Filter Paper, Hemp Dot Filter Cloth, Polyester Filter Cloth, Needle Punched Filter Cloth, Polyester Filter Cloth

Industrial filter cloth is a high-performance filtering material used for solid-liquid or gas-solid separation, widely used in industries such as mining, chemical, environmental protection, food processing, metallurgy, etc. Its core function is to separate solid particles, suspended solids, or dust in the mixture through physical interception or adsorption, thereby achieving material purification, recovery, or environmentally friendly emissions.

1、 Working principle

Industrial filter cloth forms a dense filtering layer through its fiber weaving structure. When liquid or gas flows through, particles are trapped on the surface or internal pores of the filter cloth, and clean fluid is discharged through the filter cloth. According to the process requirements, industrial filter cloth can work in combination with pressure filtration (such as filter press), vacuum filtration (such as belt filter), or gravity filtration.

2、 Material and Type

1. Common materials:

Polyester fiber (PET): acid and alkali resistant, high strength, suitable for general industrial filtration (such as sewage treatment, mineral dewatering).

Polypropylene (PP): Strong corrosion resistance, lightweight, and low cost, suitable for the chemical or food industries.

Nylon (PA): Good wear resistance, suitable for high wear environments (such as slurry filtration).

Fiberglass: High temperature resistant (up to 280 ℃), used for high-temperature flue gas dust removal or molten metal filtration.

PTFE (polytetrafluoroethylene): resistant to strong acids, strong alkalis, and high temperatures, suitable for extreme chemical environments.

2. Weaving structure:

Monofilament filter cloth: Smooth surface, easy to clean, suitable for precision filtration (such as clarifying edible oil).

Multi layer interwoven filter cloth with strong dirt holding capacity, suitable for high solid content liquids (such as sludge dewatering).

Non woven filter cloth: randomly arranged fibers with high porosity, used for air filtration or coarse liquid filtration.

3. Filtering accuracy:

The precision range of industrial filter cloth is wide, ranging from 1 micron to several millimeters, and can be selected according to needs:

Coarse filtration (over 100 microns): intercepts large particles such as mineral sand and sawdust.

Fine filtration (1-100 microns): Separate small particles such as dust and metal powder.

3、 Core advantages

1. Efficient separation: High porosity and precise pore size design improve filtration efficiency and flux.

2. Strong durability: Wear resistant, stretch resistant, suitable for high-pressure and high flow conditions.

3. Wide adaptability: high temperature resistance, corrosion resistance, and can handle complex media such as acid, alkali, oil, organic solvents, etc.

4. Economic and environmental protection: Reusable for cleaning and use, reducing consumable costs and minimizing waste generation.

4、 Application Fields

1. Mining and Metallurgy:

Slurry dewatering (such as gold and copper tailings treatment).

Molten metal filtration in metal smelting (such as aluminum liquid purification).

2. Chemical and Environmental Protection:

Solid liquid separation of chemical raw materials (such as titanium dioxide and calcium carbonate).

Wastewater treatment (sludge filtration, industrial wastewater purification).

Smoke dust removal (filter bag in bag filter).

3. Food and pharmaceuticals:

Clarify and filter syrup and juice.

Separation of bacterial cells from fermentation broth (such as antibiotic production).

4. Energy industry:

Catalyst recovery in petroleum refining.

Coal slurry dewatering in coal washing.

5、 Selection and usage precautions

1. Selection principle:

Select the material and pore size based on the properties of the filter medium (particle size, temperature, acidity or alkalinity).

Determine the size and structure of the filter cloth based on the type of filtration equipment (plate and frame filter press, centrifuge, belt filter).

2. Maintenance points:

Regularly clean the filter cloth to prevent pore blockage (high-pressure water gun or chemical cleaning can be used).

Avoid overloading and prevent the filter cloth from tearing or deforming.

When used in high temperature or corrosive environments, it is necessary to monitor the aging of the filter cloth and replace it in a timely manner.

3. Environmental protection treatment:

Waste filter cloth needs to be classified and processed according to its material, and some can be recycled and reused (such as polyester and polypropylene).

Filter cloth containing hazardous chemicals should be disposed of as hazardous waste to avoid environmental pollution.

Industrial filter cloth is an indispensable separation medium in industrial production, and its performance directly affects filtration efficiency and cost. Through scientific selection and standardized maintenance, the lifespan of filter cloth can be significantly extended, resource utilization can be improved, and environmental protection and safety production requirements can be met. In complex working conditions, combining coating treatment (such as anti-static and oleophobic coatings) or composite material design can further expand its application scenarios and efficiency.

Send Inquiry to This Supplier

You May Also Like

-

Paper Industrial Shredder Aluminum Foil ShredderNegotiableMOQ: 1 Set

-

Belt Filter Press Used for Wastewater Treatment and Paper Industry for SaleUS$ 1,000 - 88,888MOQ: 1 Set

-

CATERPILLAR 321-2411 CAT 3212411 Truck Air Filter for ENGINE - INDUSTRIAL C4.4,C7.1NegotiableMOQ: 1 Piece

-

ABB AOFC-02NegotiableMOQ: 1 Piece

-

Industrial Dust MaskUS$ 1.5 - 4MOQ: 200 Pieces

-

0.01 Micro Air Filter Industrial Compressed Air FilterNegotiableMOQ: 1

-

Hot Selling Original Oil Filter Paper For ExcavatorNegotiableMOQ: 1

-

Genuine Ail Filter Parts for SEM656D Loader Fast Delivery for Construction IndustriesUS$ 9.00 - 10.00MOQ: 1 Unit

-

Shredder Machine/double Shaft Shredder/paper Shredder Machine IndustrialUS$ 2600 - 12096MOQ: 1 Set

-

Nylon Filter Cloth 80-500 Mesh White Screen Filtration Food Grade Water Industrial ClothUS$ 1 - 20MOQ: 10 Square Meters